Biomedical hydrogel coating layer with 'sandwich' structure and preparation method of biomedical hydrogel coating layer

A sandwich structure, biomedical technology, applied in the field of medical materials, can solve the problems of poor film stability and fast drug release rate, and achieve the effect of improving binding force, good interface binding force, and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

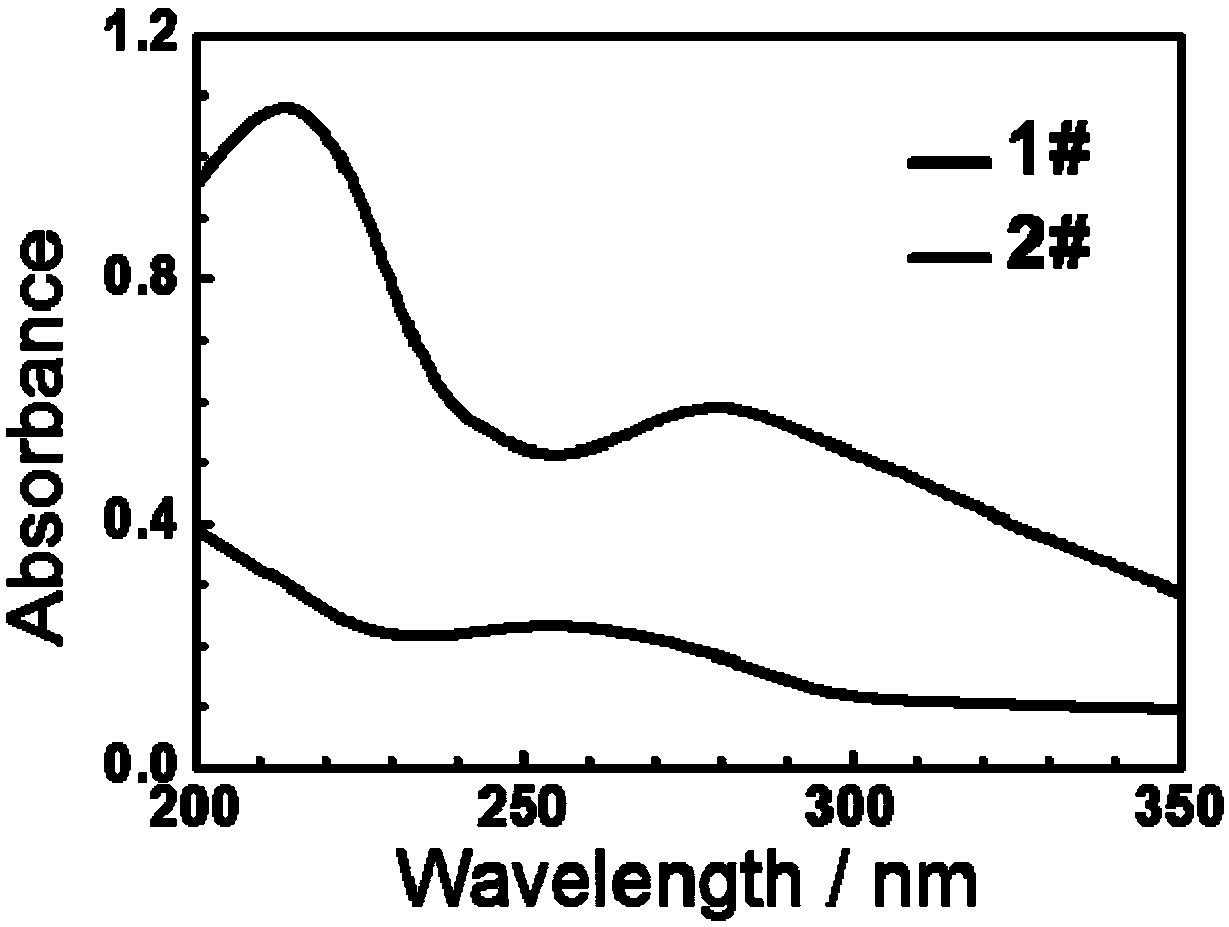

Image

Examples

Embodiment 1

[0032] A method for preparing a biomedical hydrogel coating with a "sandwich" sandwich structure, obtained by the following steps:

[0033] A. Clean and dry the silicon wafers to be modified;

[0034] B. Place the sample obtained in step A in PBS buffer solution with pH = 8.5, then add dopamine with a concentration of 3 mg / ml into the solution, react at 10°C for 2 hours, wash with deionized water for 3 to 5 times, and N 2 Dried and immediately put into a vacuum drying oven for future use;

[0035] C. First put the sample obtained in step B into a chitosan (CHI) solution with a concentration of 1mM and pH=7.4, react for 10min at 20°C, take it out and wash it with deionized water for 3 times; then put the sample into In an epigallocatechin gallate (EGCG) solution with a concentration of 0.2mM and pH=7.0, react at 10°C for 10min, take it out and wash it with deionized water for 3 times; then put the sample in a concentration of 0.2mM , in an anti-lymphocyte immunoglobulin (ALg...

Embodiment 2

[0038] A method for preparing a biomedical hydrogel coating with a "sandwich" sandwich structure, obtained by the following steps:

[0039] A. Clean and dry the stainless steel base material;

[0040] B. Place the sample obtained in step A in Tris-HCl buffer solution with pH = 8.5, then add dopamine with a concentration of 1.2 mg / ml into the solution, react for 2 hours at 20°C, and wash with deionized water for 3 to 5 times after N 2 Dried and immediately put into a vacuum drying oven for future use;

[0041] C. First put the sample obtained in step B into a chitosan (CHI) solution with a concentration of 0.01mM and pH=6, react for 30min at 10°C, take it out and wash it with deionized water for 3 times; then the obtained sample Put it into a gallic acid solution with a concentration of 0.01mM and pH=5.5, react at 30°C for 5 minutes, take it out and wash it with deionized water for 3 times; then put the obtained sample into a collagen solution with a concentration of 0.01mM a...

Embodiment 3

[0044] A method for preparing a biomedical hydrogel coating with a "sandwich" sandwich structure, obtained by the following steps:

[0045] A, the titanium sheet material is cleaned and dried;

[0046] B. Place the sample obtained in step A in a triethanolamine buffer solution with pH = 8, then add dopamine at a concentration of 2.0 mg / ml to the solution, react for 4 hours at 10°C, and wash with deionized water for 3 to 5 times via N 2 Dried and immediately put into a vacuum drying oven for future use;

[0047] C. First put the sample obtained in step B into a lysine solution with a concentration of 2mM and pH=7.4, react at 50°C for 4min, take it out and wash it with deionized water for 3 times; then put the sample into a lysine solution with a concentration of 1mM , pH = 6.8 epigallocatechin gallate (EGCG) solution, under the condition of 10 ℃, reacted for 20min, took out and washed 3 times with deionized water; then put the sample into 1mM, pH = 6.8 polyphenylene In sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com