Nanosheet sulfide hollow sphere and preparation method and application thereof

A nanosheet and sulfide technology, applied in the field of nanomaterials, can solve the problems of low first Coulombic efficiency, unstable material structure, easy pulverization and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

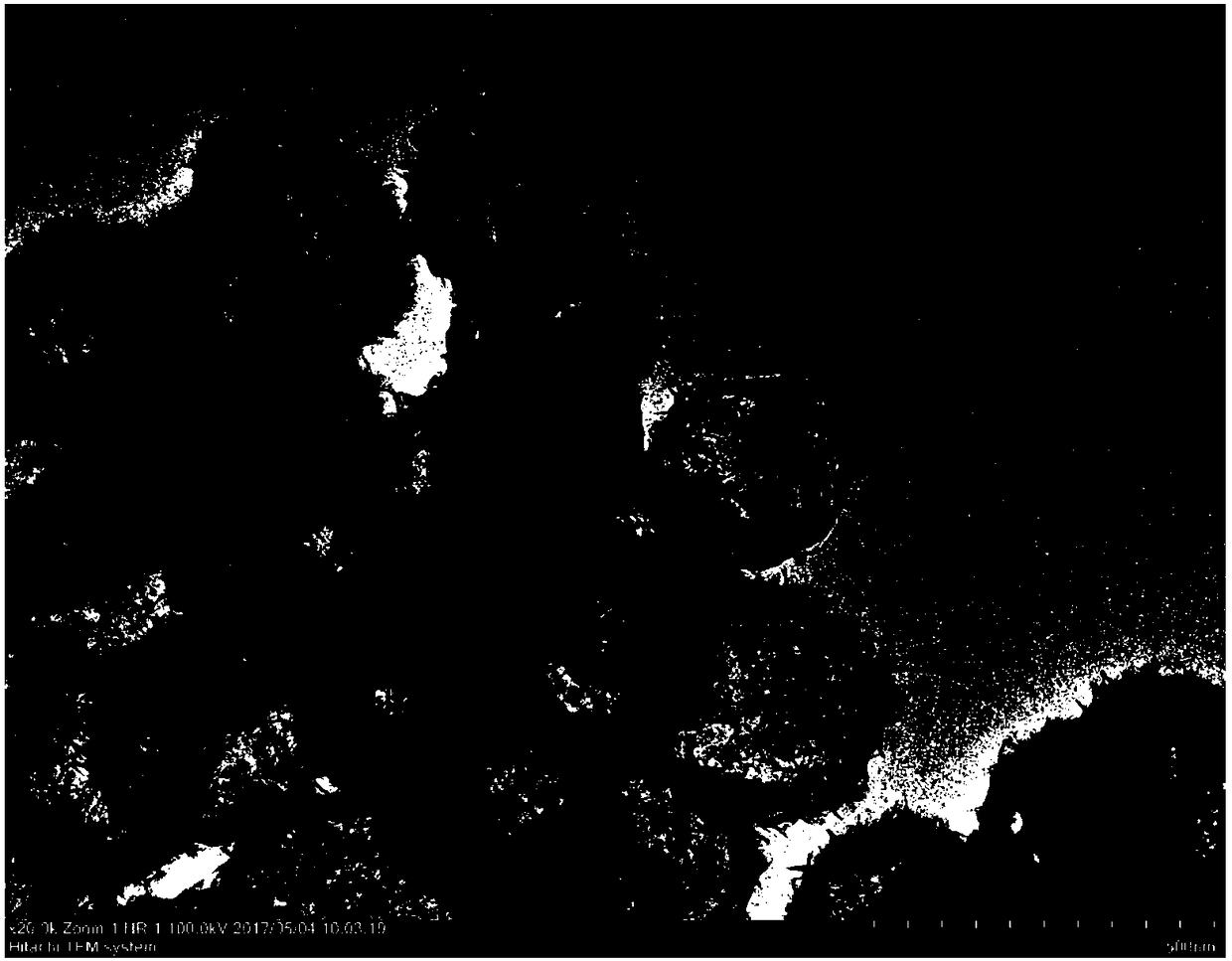

Image

Examples

preparation example 1

[0046] SiO 2 Ball preparation:

[0047] It is prepared on the basis of the method described in the document titled "Tailoring the Void Size of Iron Oxide@Carbon Yolk–Shell Structure for Optimized Lithium Storage", specifically: first drop 6ml of tetraethyl silicate (TEOS) Add 160mL isopropanol and 40mL distilled water (H 2 O) was stirred for 15 minutes, then 6 mL of NH 3 ·H 2 O was added to the above transparent solution and stirred for about 10 minutes until the transparent solution gradually turned milky white, and continued stirring at 25°C for 24 hours; finally, the white precipitate was collected by centrifugation, washed several times with deionized water and absolute ethanol, and then heated at 60 °C in a vacuum oven overnight.

Embodiment 1

[0049] 1) Add 3mmol of CoSO 4 ·7H 2O and 10mmol of thiourea were dissolved in 20mL of aqueous solution, and another 0.120g of SiO 2 Balls (average particle size: 350nm) were uniformly dispersed in 20mL aqueous urea solution (the content of urea was 8mmol), and then the two were continuously stirred, and reacted at 150°C for 24 hours; then the system was left to stand 12h, the filter cake was taken by suction filtration to obtain a black precipitate;

[0050] 2) Dry the black precipitate in a vacuum drying oven (the drying temperature is 70° C., and the drying time is 20 h) to a constant weight to obtain a black powder, that is, nanosheet sulfide hollow spheres A1.

Embodiment 2

[0052] According to the method of Example 1, the nanosheet sulfide hollow spheres A2 are prepared, the difference is that CoSO 4 ·7H 2 The consumption of O is 1mmol, the consumption of thiourea is 3mmol, the consumption of urea is 2.5mmol, SiO 2 The amount of balls used was 0.04 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com