A method for preparing a transfer-free, high-adhesion metal grid transparent electrode

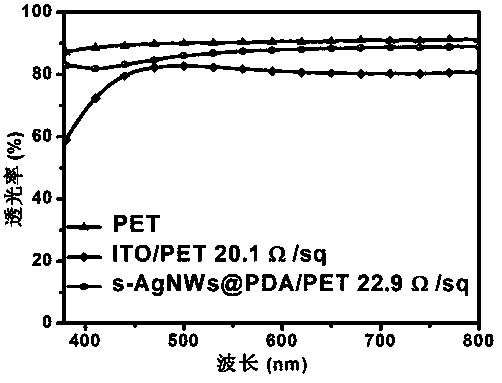

A metal grid and transparent electrode technology, which is applied in the manufacture of conductive/semiconductive layer equipment, cable/conductor manufacturing, circuits, etc., can solve the complex transfer process, poor adhesion, and limitations of large-area flexibility of organic optoelectronic devices and other problems, to achieve the effect of low cost, simple method, super mechanical bending resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]

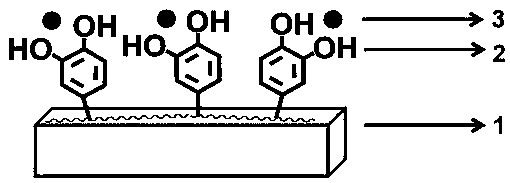

[0035] a) Weigh 0.09 g of tris(hydroxymethyl)methylamine hydrochloride and 0.17 g of tris(hydroxymethyl)aminomethane and dissolve them in 200 mL of deionized water, add 0.4 g of dopamine (DA) to dissolve and form a polydopamine (PDA) solution .

[0036]b) Immediately immerse the oxygen plasma-treated substrate (polyethylene terephthalate, PET) in the buffer solution a) and react for 20 min, and put the PDA-coated substrate in an oven at 60 °C for 15 min .

[0037] c) Add 0.815 g of silver nitrate into 20 mL of deionized water, stir to dissolve it, add dropwise 40 μL of 0.25mol / L potassium hydroxide solution, and add 28% ammonia water (about 950 μL) dropwise until the solution becomes cloudy again clarify.

[0038] d) Add 6.84 g of glucose into 20 mL of deionized water, stir to dissolve it, and add it into 10 mL of anhydrous methanol solution as a reducing agent.

[0039] e) The solutions obtained in steps c) and d) were quickly stirred and poured into a watch gl...

Embodiment 2

[0043]

[0044] a) Weigh 0.0301 g of polyethyleneimine (PEI), and dissolve it in 10 mL of deionized water by ultrasonic.

[0045] b) Spin-coat 50 μL of the solution in a) on the substrate treated with oxygen plasma at a speed of 4000 rpm for 1 min, put the PEI-coated substrate in an oven for 60 min and control the temperature at 60°C .

[0046] c) Add 0.815 g of silver nitrate into 20 mL of deionized water, stir to dissolve it, add dropwise 40 μL of 0.25mol / L potassium hydroxide solution, and add 28% ammonia water (about 950 μL) dropwise until the solution becomes cloudy again clarify.

[0047] d) Add 6.84 g of glucose into 20 mL of deionized water, stir to dissolve it, and add it into 10 mL of anhydrous methanol solution as a reducing agent.

[0048] e) The solutions obtained in steps c) and d) were quickly stirred and poured into a watch glass, and the substrate containing the surface coating was placed in the reaction for 10 min.

[0049] f) Place the conductive film ...

Embodiment 3

[0052]

[0053] a) Weigh 0.0503 g of polyallylamine (PAA), and ultrasonically dissolve it in 10 mL of deionized water.

[0054] b) Spin-coat 50 μL of the solution in a) on the substrate treated with oxygen plasma at a speed of 4000 rpm for 1 min, put the PAA-coated substrate in an oven for 60 min and control the temperature at 60°C .

[0055] c) Add 0.815 g of silver nitrate into 20 mL of deionized water, stir to dissolve it, add dropwise 40 μL of 0.25mol / L potassium hydroxide solution, and add 28% ammonia water (about 950 μL) dropwise until the solution becomes cloudy again clarify.

[0056] d) Add 6.84 g of glucose into 20 mL of deionized water, stir to dissolve it, and add it into 10 mL of anhydrous methanol solution as a reducing agent.

[0057] e) The solutions obtained in steps c) and d) were quickly stirred and poured into a watch glass, and the substrate containing the surface coating was placed in the reaction for 10 min.

[0058] f) Place the conductive film ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com