Copper lithium nickelate positive electrode material and preparation method thereof and lithium ion battery

A technology of lithium cupronickel oxide and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., and can solve the problem of unsatisfactory electrochemical performance of lithium-ion batteries, poor electrochemical performance such as reversible capacity, and large particle size of positive electrode materials. problem, to achieve the effect of stable cycle performance, good crystallinity and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

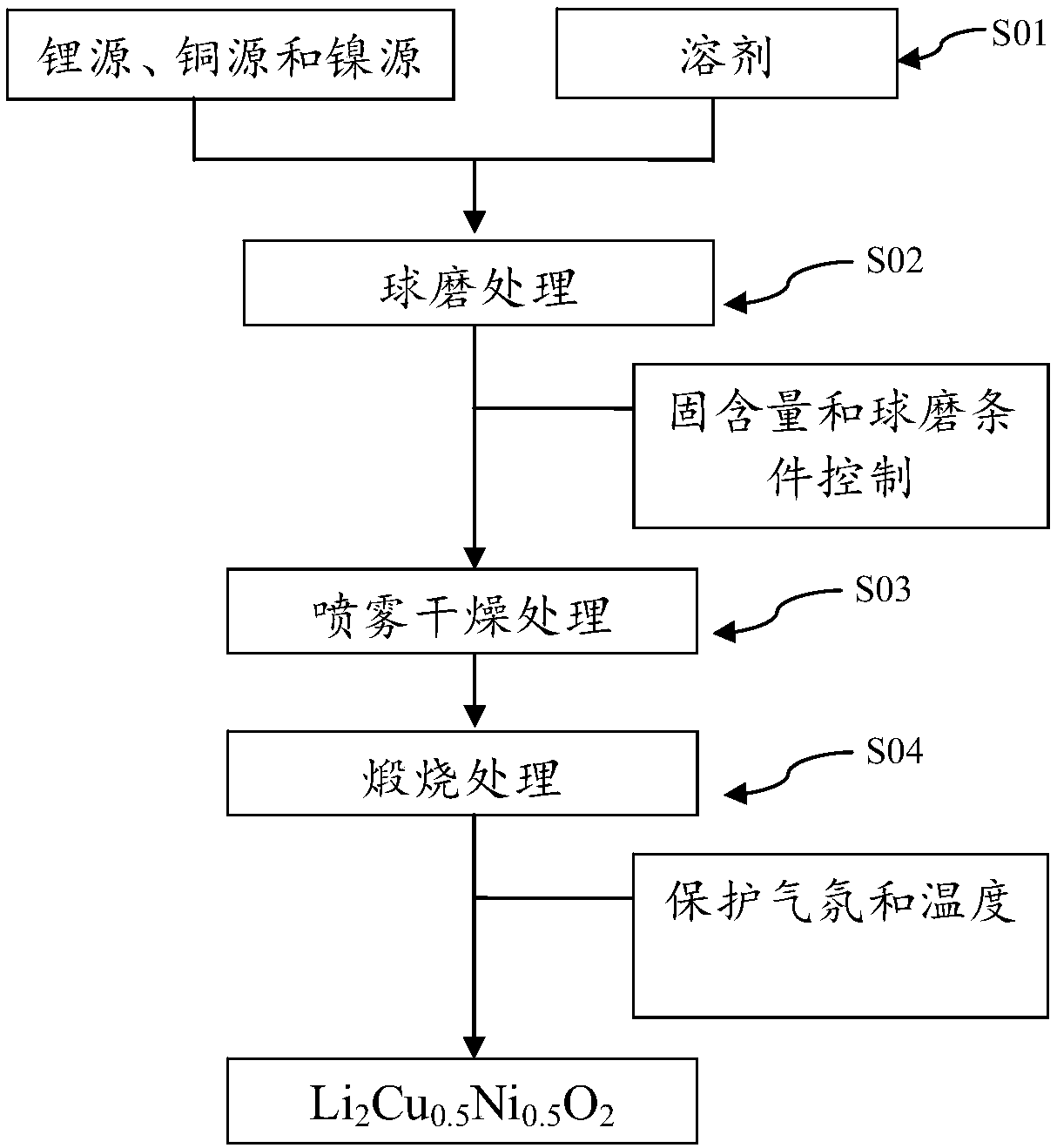

[0026] On the other hand, the embodiment of the present invention provides a preparation method of the above-mentioned lithium cupronickel oxide positive electrode material. The preparation method technological process of described lithium copper nickelate cathode material is as follows figure 1 As shown, it includes the following steps:

[0027] S01: According to Li 2 Cu 0.5 Ni 0.5 o 2 The stoichiometric ratio obtains lithium source, copper source and nickel source respectively;

[0028] S02. Prepare a mixture slurry containing lithium source, copper source and nickel source: add the lithium source, copper source and nickel source into a solvent, and perform ball milling to obtain a mixture slurry;

[0029] S03. Spray-drying the mixture slurry: performing spray-drying treatment on the mixture slurry to obtain lithium copper nickelate precursor powder;

[0030] S04: Sintering the precursor powder in a protective atmosphere.

[0031] Wherein, described Li in above-mentio...

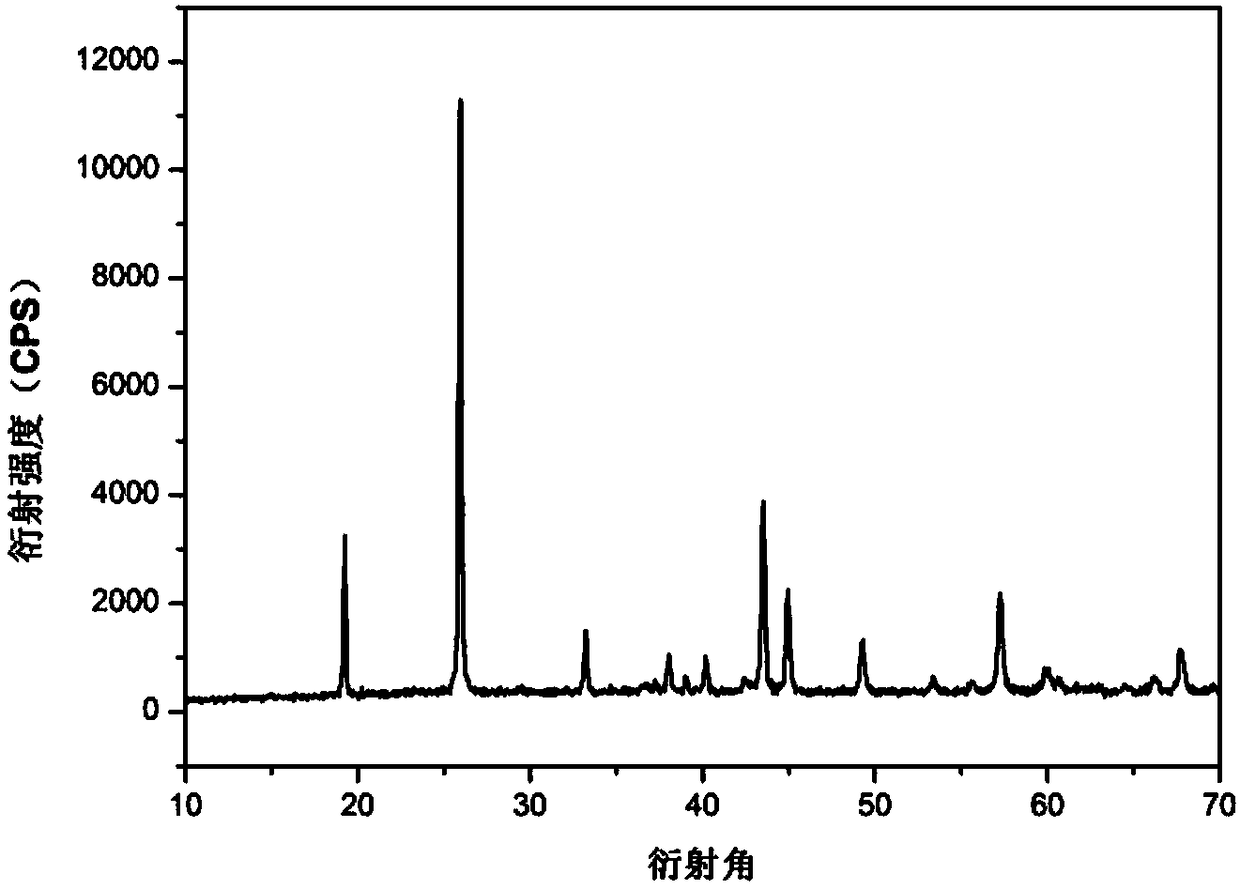

Embodiment 1

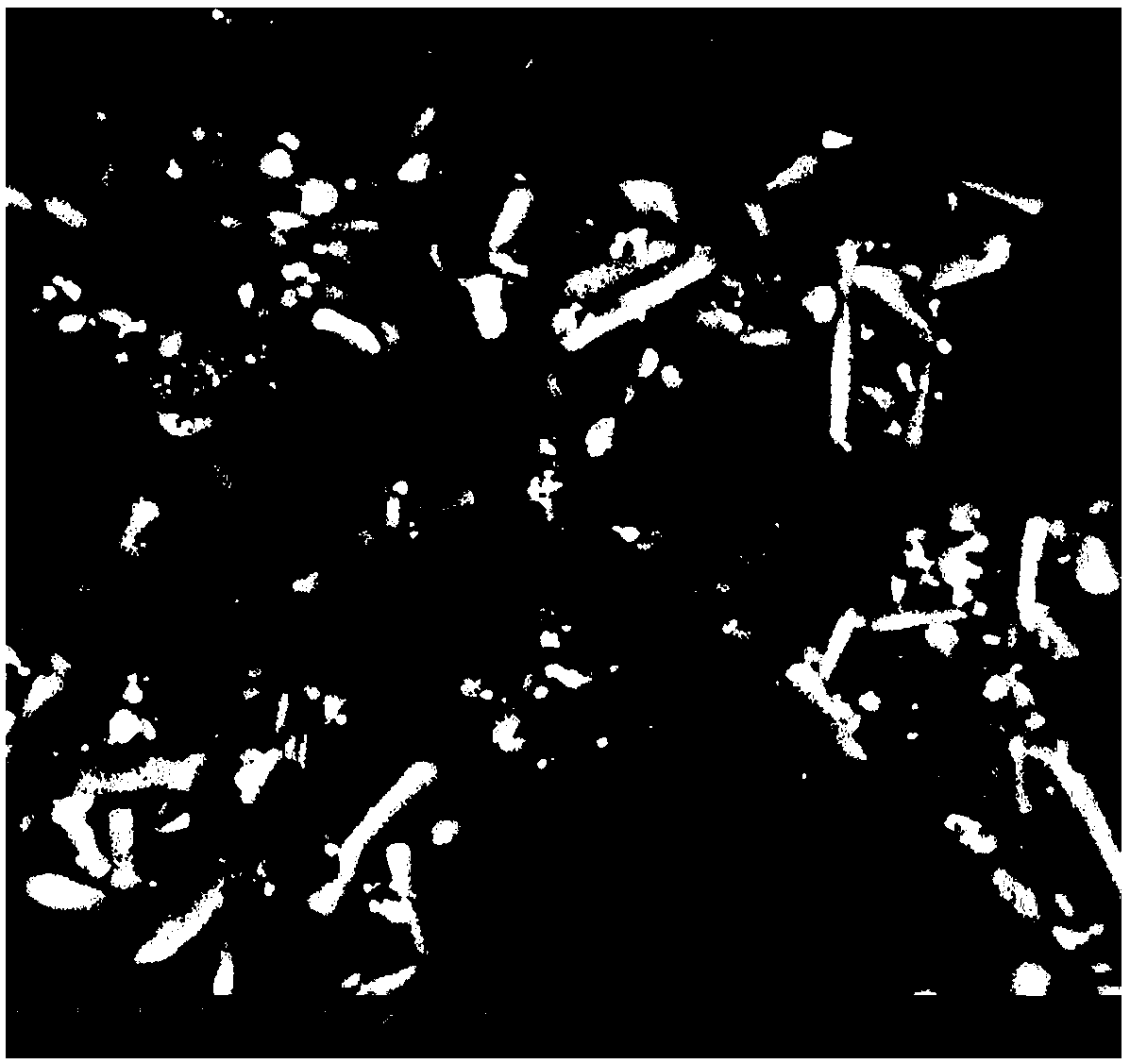

[0046] This embodiment provides a Li 2 Cu 0.5 Ni 0.5 o 2 Lithium cupronickel oxide positive electrode material and preparation method thereof. The crystal grain morphology of the lithium cuproniclate positive electrode material in this embodiment is a rod-like structure.

[0047] Its preparation method comprises the following steps:

[0048] (1) 90 parts of lithium hydroxide are added into 400 parts of deionized water for ultrasonic dissolution to obtain a clear solution of lithium hydroxide;

[0049] (2) Add the solution of step (1) into a ball mill for ball milling, then add 40 parts of copper oxide, 37.5 parts of nickel oxide and 100 parts of deionized water for ball milling, and control the solid content of the slurry to 25%;

[0050] (3) Stir the slurry in step (2) evenly and then spray-dry at 170°C, feed rate 13ml / min, needle pass frequency 10 times / min, and obtain spherical precursor powder;

[0051] (4) After calcining the precursor powder obtained in step (3) in...

Embodiment 2

[0055] This embodiment provides a Li 2 Cu 0.5 Ni 0.5 o 2 Lithium cupronickel oxide positive electrode material and preparation method thereof. The crystal grain morphology of the lithium cuproniclate positive electrode material in this embodiment is a rod-like structure.

[0056] Its preparation method comprises the following steps:

[0057] (1) 90 parts of lithium hydroxide are added into 400 parts of deionized water for ultrasonic dissolution to obtain a clear solution of lithium hydroxide;

[0058] (2) Add the solution of step (1) into a ball mill for ball milling, then add 40 parts of copper oxide, 37.5 parts of nickel oxide and 100 parts of deionized water for ball milling, and control the solid content of the slurry to 25%;

[0059] (3) Stir the slurry in step (2) evenly and then spray-dry at 170°C, feed rate 10ml / min, needle pass frequency 8 times / min, and obtain spherical precursor powder;

[0060] (4) After calcining the precursor powder obtained in step (3) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com