A preparation method of high weather resistance nanometer rutile titanium dioxide

A technology of nano-rutile and titanium dioxide, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as difficult industrial production, affecting product purity, and difficult conditions to control, so as to achieve easy industrial production and improve the effect of alkali dissolution , the effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

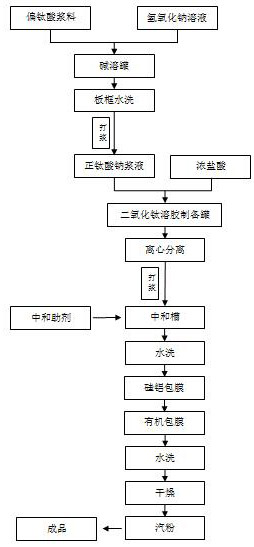

[0050] A preparation method of high weather resistance nano rutile titanium dioxide, the preparation process is as follows:

[0051] (1) Pump the metatitanic acid slurry with a concentration of 250g / L and the sodium hydroxide solution with a concentration of 600g / L into the metering tank respectively and preheat them. The mass ratio of sodium hydroxide to metatitanic acid is 1.8:1;

[0052] (2) After the sodium hydroxide solution is preheated to 90°C and the metatitanic acid slurry is preheated to 60°C, put the sodium hydroxide solution into the alkali-soluble tank first, and then put the preheated solution within 30 minutes The metatitanic acid slurry was put into an alkali solution tank, and the mixed solution was stirred at 105°C for 2 hours;

[0053] (3) Cool the mixture to room temperature, pump it into a plate and frame filter press for water washing, wash until the content of sodium hydroxide in the mixture is 4g / L, and unload to obtain the alkali-soluble material;

[...

Embodiment 2

[0071] A preparation method of high weather resistance nano rutile titanium dioxide, the preparation process is as follows:

[0072] (1) Pump the metatitanic acid slurry with a concentration of 280g / L and the sodium hydroxide solution with a concentration of 650g / L into the metering tank respectively and preheat them. The mass ratio of sodium hydroxide to metatitanic acid is 1.9:1;

[0073] (2) After the sodium hydroxide solution is preheated to 100°C and the metatitanic acid slurry is preheated to 70°C, put the sodium hydroxide solution into the alkali-soluble tank first, and then put the preheated solution within 30 minutes Put the metatitanic acid slurry into an alkali solution tank, and stir the mixed solution at 110°C for 2 hours;

[0074] (3) Cool the mixture to room temperature, pump it into a plate-and-frame filter press for water washing, wash until the content of sodium hydroxide in the mixture is 3g / L, and unload to obtain the alkali-soluble material;

[0075] (4) ...

Embodiment 3

[0092] A preparation method of high weather resistance nano rutile titanium dioxide, the preparation process is as follows:

[0093] (1) Pump the metatitanic acid slurry with a concentration of 285g / L and the sodium hydroxide solution with a concentration of 680g / L into the metering tank respectively and preheat them. The mass ratio of sodium hydroxide to metatitanic acid is 1.9:1;

[0094] (2) After the sodium hydroxide solution is preheated to 105°C and the metatitanic acid slurry is preheated to 78°C, put the sodium hydroxide solution into the alkali-soluble tank first, and then put the preheated solution within 30 minutes The metatitanic acid slurry was put into an alkali solution tank, and the mixed solution was stirred at 112°C for 3 hours;

[0095] (3) Cool the mixture to room temperature, pump it into a plate and frame filter press for water washing, wash until the content of sodium hydroxide in the mixture reaches 3.5g / L, and unload to obtain the alkali-soluble materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com