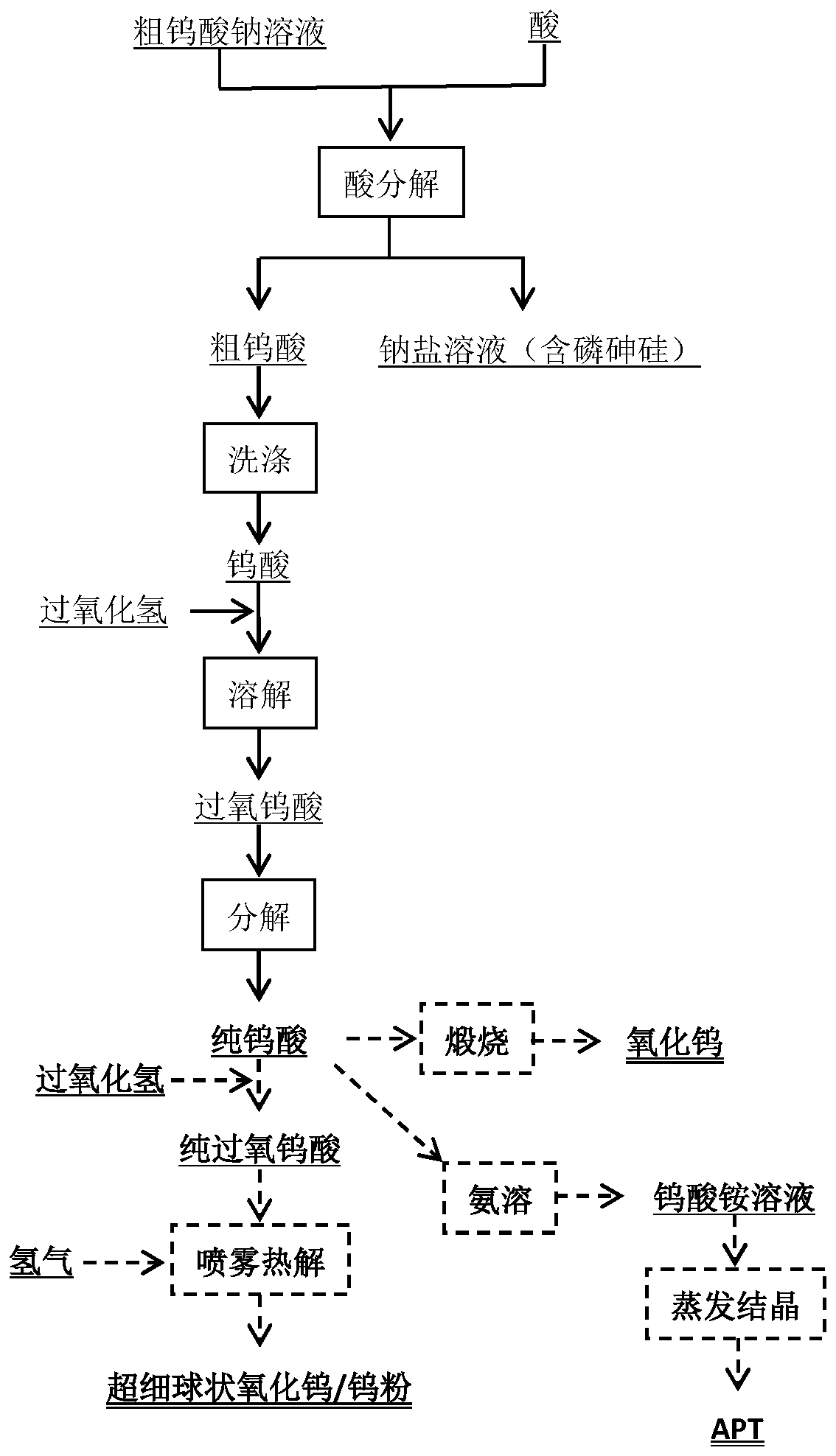

A method for preparing tungsten products from crude sodium tungstate solution

A technology of sodium tungstate and solution, which is applied in the preparation of tungsten compounds, chemical instruments and methods, tungsten oxide/tungsten hydroxide, etc. It can solve the problems of complexity and high content of impurities, difficult products, and no tungstic acid purity detection. , to achieve the effect of increasing product added value and reducing environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing tungsten products from crude sodium tungstate, comprising the steps of:

[0051] (1) Add 100g / L sulfuric acid to WO 3 In the sodium tungstate solution (scheelite alkali pressure cooking) with a concentration of 152g / L, the pH value of the solution is controlled at -0.5, the reaction temperature is 90°C, and the reaction time is 0.5 hours. After the reaction is completed, tungstic acid precipitate and Filtrate; the precipitation rate of tungsten was detected to be 98.5%;

[0052] (2) Contact the filtrate with D301 resin for 1 hour to absorb the tungsten in it, and control the reaction temperature to 50°C; add sulfuric acid to the solution after the adsorption and return to step (1) to precipitate tungsten from the sodium tungstate solution;

[0053] (3) after the tungstic acid precipitation that step (1) obtains is washed, then be the hydrogen peroxide solution dissolving of 30% with mass concentration, the mol ratio of the add-on of hydrogen pero...

Embodiment 2

[0058] A method for preparing tungsten products from crude sodium tungstate, comprising the steps of:

[0059] (1) Add 150g / L hydrochloric acid to WO 3 In the sodium tungstate solution with a concentration of 258g / L ( wolframite alkali pressure cooking), the pH value of the solution is controlled at 0.1, the reaction temperature is 85°C, and the reaction time is 2 hours. After the reaction is completed, it is filtered to obtain tungstic acid precipitate and filtrate ; The precipitation rate of tungsten was detected to be 99.2%

[0060] (2) Contact the filtrate with "30% N235 + 10% TBP + kerosene" at a water-to-oil ratio of 1:1 for 10 minutes to extract the tungsten, and control the extraction temperature to 50°C; add hydrochloric acid to the raffinate and return to step (1) Used to precipitate tungsten from sodium tungstate solution;

[0061] Alternatively, contact the filtrate with D301 resin for 1 hour to absorb the tungsten in it, and control the reaction temperature to 5...

Embodiment 3

[0067] A method for preparing tungsten products from crude sodium tungstate, comprising the steps of:

[0068] (1) Add 150g / L nitric acid to WO 3 In the sodium tungstate solution with a concentration of 300g / L (scheelite soda pressure cooking), add solid tungstic acid with 10% of the mass of tungsten in the sodium tungstate solution as a seed crystal at the same time, control the pH value of the solution to 1.1, and the reaction temperature is 100°C, the reaction time is 2 hours, after the reaction is completed, the tungstic acid precipitate and filtrate are obtained by filtration; the precipitation rate of tungsten is 99.7% after testing

[0069] (2) Contact the filtrate with "40% TBP + 10% 2-octanol + kerosene" at a water-to-oil ratio of 2:1 to extract the tungsten in it for 15 minutes, and control the extraction temperature to 50°C; add nitric acid to the raffinate and return to the step (1) Used to precipitate tungsten from sodium tungstate solution;

[0070] Alternative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com