Extraction process for active ingredients of pericarpium trichosanthis

A technology of active ingredients and extraction technology, which is applied in the field of extraction technology of active ingredients of Trichosanthes pipis, can solve the problems that there are no reasonable methods for extracting other ingredients, and the value of Trichosanthes peels cannot be effectively utilized, so as to achieve maximum utilization and easy Operation, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

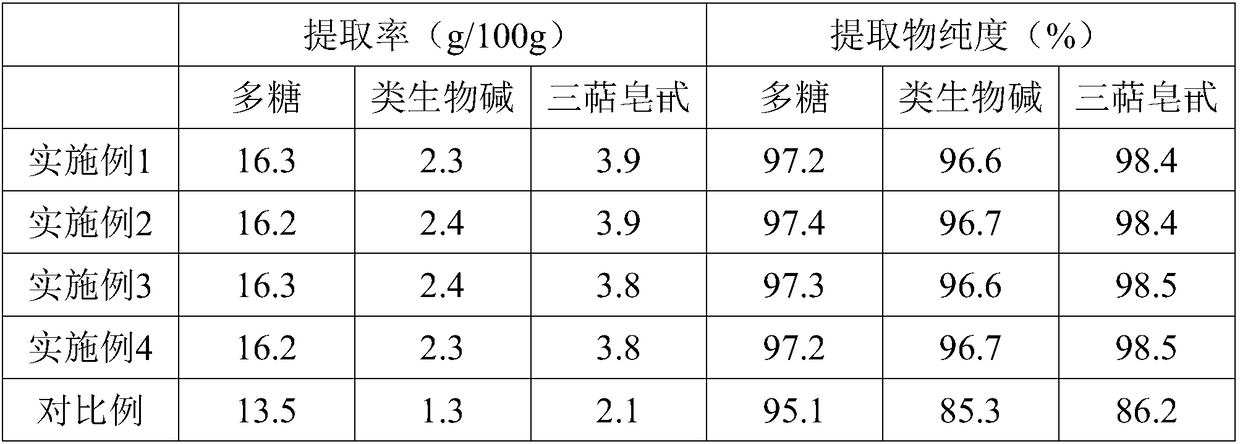

Examples

Embodiment 1

[0027] A process for extracting the active ingredient from Trichosanthes rind, comprising the following steps:

[0028] (1) Cleaning: Soak Trichosanthes rind in the mixed solution of magnesium sulfate of 6% mass concentration and molybdenum nitrate of 30% mass concentration for 20min, then rinse with water, dry with air cooler, pulverize, pass through a 30-mesh sieve, and obtain Trichosanthes skin powder;

[0029] (2) Freezing: Soak the Trichosanthes husk powder with water until the water content is 16%. The soaked Trichosanthes husk powder is frozen at -10°C for 4 hours, then thawed in water at 5°C, and put into a drying box after thawing Warm up to 70°C and keep warm for 10h;

[0030] (3) extracting polysaccharides: add Trichosanthes husk powder to powder quality 8% cellulase, 3% citric acid, 2% tert-butyl hydroquinone, 2% diallyl isophthalate and mix Uniform, add acetic acid to the mixture to adjust the pH to 6, enzymatic hydrolysis reaction at 28°C for 6h, after the reac...

Embodiment 2

[0033] A process for extracting the active ingredient from Trichosanthes rind, comprising the following steps:

[0034] (1) Cleaning: Soak Trichosanthes rind in the mixed solution of magnesium sulfate of 7% mass concentration and molybdenum nitrate of 25% mass concentration for 30min, then rinse with water, dry with air cooler, pulverize, and pass through a 30-mesh sieve to obtain Trichosanthes skin powder;

[0035] (2) Freezing: soak the Trichosanthes husk powder with water until the water content is 17%, freeze the soaked Trichosanthes quinces skin powder at -10°C for 3 hours, then thaw it in water at 10°C, and put it in a drying box after thawing Warm up to 65°C and keep warm for 11 hours;

[0036](3) extracting polysaccharides: add Trichosanthes husk powder to powder mass 7% cellulase, 4% citric acid, 1% tert-butyl hydroquinone, 1% diallyl isophthalate and mix Evenly, add acetic acid to the mixture to adjust the pH to 6, enzymolysis reaction at 30°C for 5 hours, after th...

Embodiment 3

[0045] A process for extracting the active ingredient from Trichosanthes rind, comprising the following steps:

[0046] (1) Cleaning: Soak Trichosanthes rind in the mixed solution of magnesium sulfate of 8% mass concentration and molybdenum nitrate of 30% mass concentration for 25min, then rinse with water, dry with air cooler, pulverize, and pass through a 30-mesh sieve to obtain Trichosanthes skin powder;

[0047] (2) Spread the melon skin powder into a thin layer of 1.5cm thick, first place the thin layer at 90°C and 0.07Mpa saturated vapor pressure for 30 minutes, and then transfer it to 120°C and 2Mpa high temperature and high pressure environment for standing 20min, then quickly collect the thin layer and put it into 3°C water to cool, then put it into a drying oven and dry it completely at 80°C after cooling, add 3.2% active aluminum in the vacuum environment and mix evenly, and stir at 300r / min After 30 minutes, add 5% hydrochloric acid solution to the mixture, stop a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com