High-strength high-temperature-resistant 3D-printing clay wet sand material and preparation method thereof

A 3D printing, high temperature resistant technology, applied in the direction of casting molding equipment, casting mold, core, etc., to achieve the effect of good air permeability, good dispersion and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A high-strength and high-temperature-resistant 3D printing clay green sand material, in parts by weight, prepared from the following weight raw materials: 240 parts of Mujie clay, 11 parts of bentonite, 20 parts of hollow ceramic microspheres, 20 parts of magnesium silicate, wood 10 parts of striatum, 12 parts of volcanic tuff, 3 parts of anhydrous calcium sulfate, 5 parts of hydroxyapatite whiskers, 15 parts of andalusite, 10 parts of nano-fluorite powder, 10 parts of light calcium carbonate, 7 parts of expanded graphite, 6 parts of sodium aluminate, 8 parts of spinel, 5 parts of aluminum starch octenyl succinate, 3 parts of carboxymethyl cellulose, 2 parts of polyethyleneimine, 10 parts of water.

[0015] A preparation method of high-strength and high-temperature-resistant 3D printing clay green sand material, comprising the following steps:

[0016] (1) Put wood grain stone, volcanic tuff, andalusite, and spinel in a calcination furnace at 800-900°C for 4-5 hours, th...

Embodiment 2

[0019] A high-strength and high-temperature-resistant 3D printing clay green sand material, in parts by weight, prepared from the following weight raw materials: 250 parts of Mujie clay, 12 parts of bentonite, 25 parts of hollow ceramic microspheres, 22 parts of magnesium silicate, wood 12 parts of grain stone, 16 parts of volcanic tuff, 3.5 parts of anhydrous calcium sulfate, 7 parts of hydroxyapatite whiskers, 20 parts of andalusite, 12 parts of nano-fluorite powder, 12 parts of light calcium carbonate, 8 parts of expanded graphite, partial 7 parts of sodium aluminate, 10 parts of spinel, 8 parts of aluminum starch octenyl succinate, 4 parts of carboxymethyl cellulose, 3 parts of polyethyleneimine, 15 parts of water.

[0020] The preparation method is the same as in Example 1.

Embodiment 3

[0022] A high-strength and high-temperature-resistant 3D printing clay green sand material, in parts by weight, prepared from the following weight raw materials: 260 parts of Mujie clay, 13 parts of bentonite, 30 parts of hollow ceramic microspheres, 25 parts of magnesium silicate, wood 14 parts of striatum, 18 parts of volcanic tuff, 4 parts of anhydrous calcium sulfate, 9 parts of hydroxyapatite whiskers, 25 parts of andalusite, 15 parts of nano-fluorite powder, 14 parts of light calcium carbonate, 9 parts of expanded graphite, 8 parts of sodium aluminate, 12 parts of spinel, 10 parts of aluminum starch octenyl succinate, 5 parts of carboxymethyl cellulose, 4 parts of polyethyleneimine, 20 parts of water.

[0023] The preparation method is the same as in Example 1.

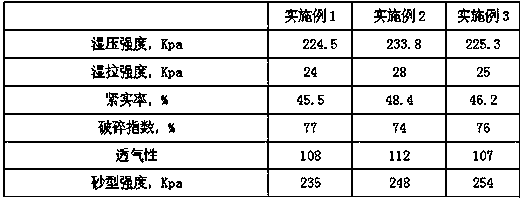

[0024] The performance test results of the high-strength and high-temperature-resistant 3D printing clay green sand material obtained in the above-mentioned Examples 1-3 are shown in the following table:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com