Modified-starch composite gel, and preparation method and application thereof

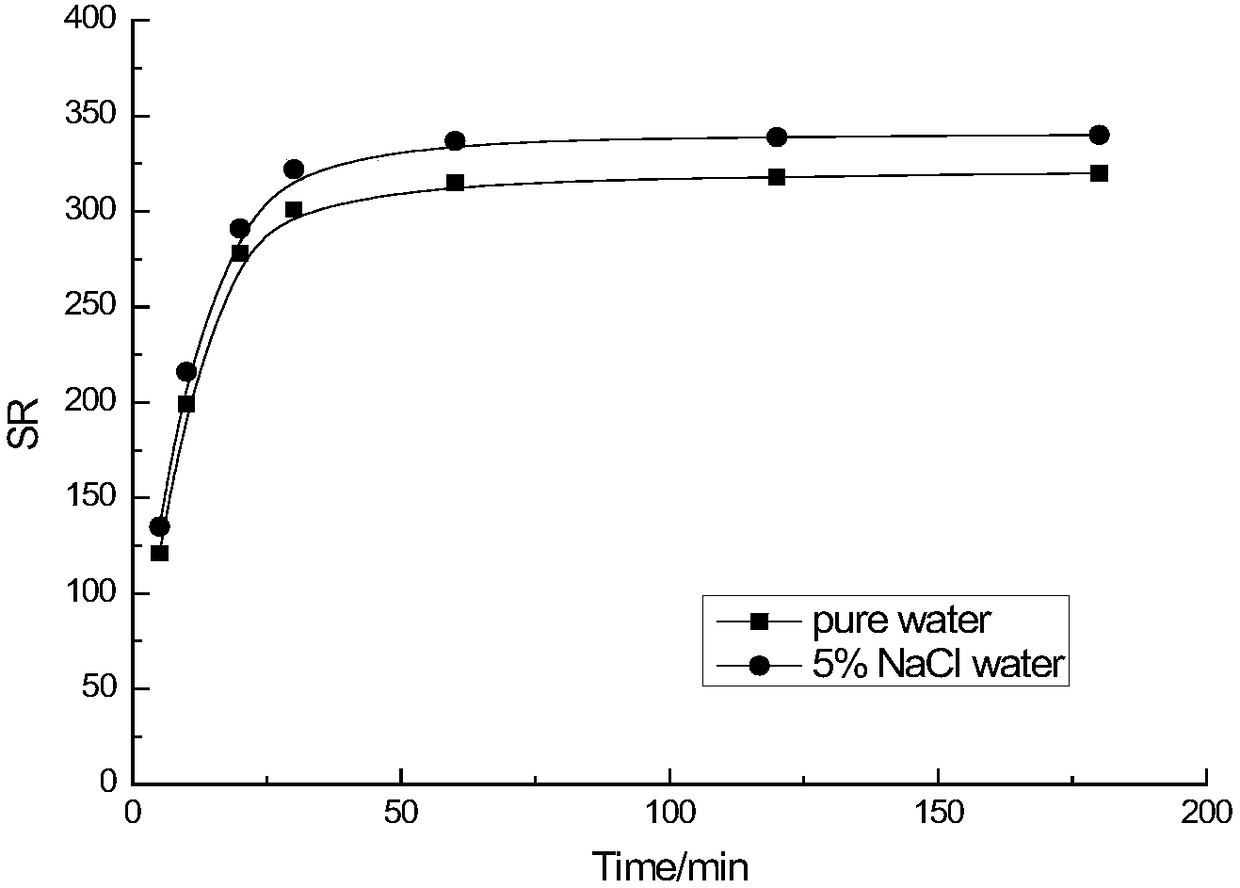

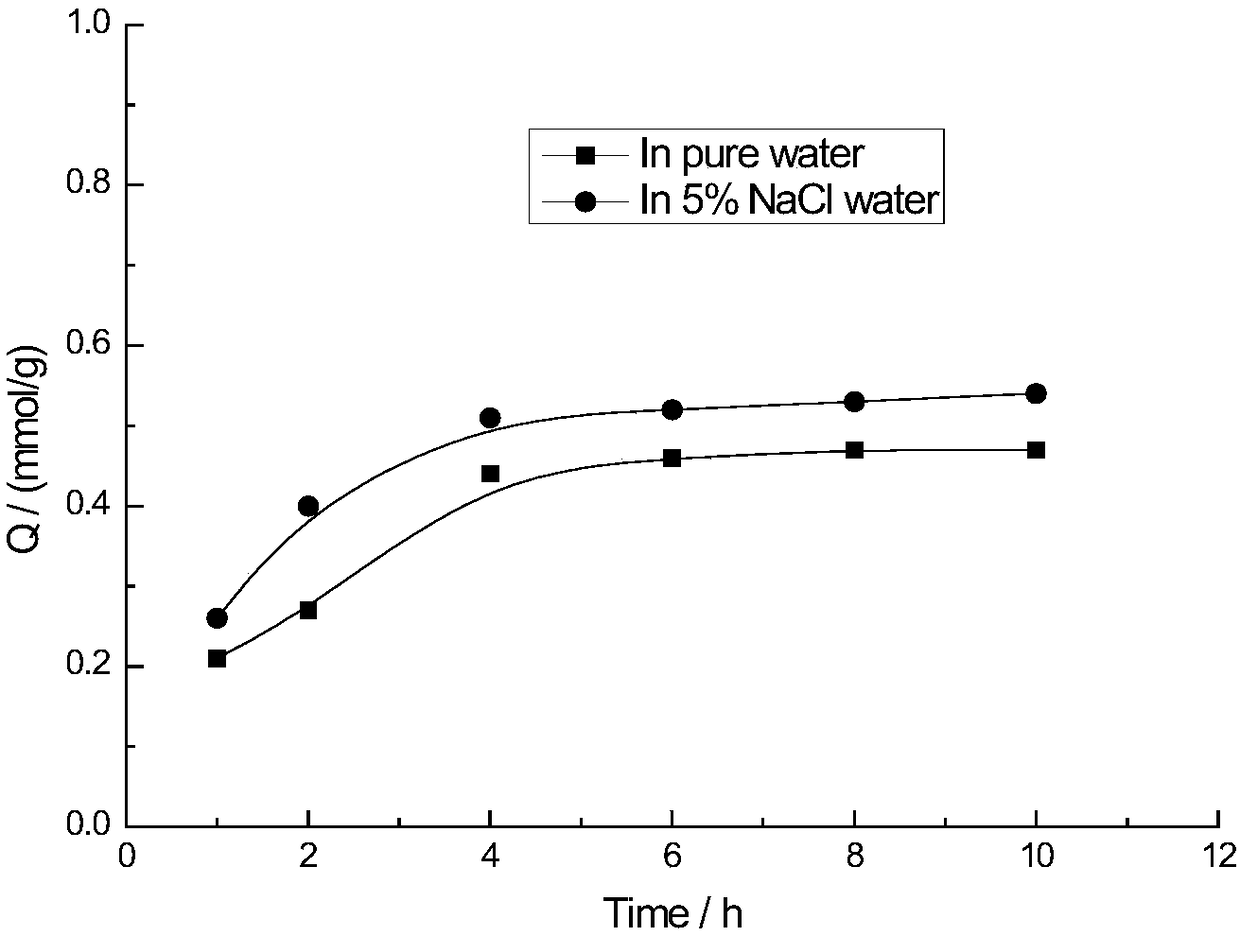

A technology of modified starch and composite gel, which is applied in the direction of chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of good fresh water absorption performance and poor salt water absorption performance, and achieve simple operation methods, swelling properties Effect of enhanced water absorption and good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Put a 250ml three-necked flask into an oil bath, add 2g of starch (potato starch) and 90ml of pure water, heat up to 85°C, condense and reflux with magnetic stirring for 1h, add 0.5g of zwitterionic monomer (the cationic group is Dimethylethylamine, the anion group is a carboxyl group, the molar ratio of the two groups is 1:1, the two groups are connected by methylene groups, and the number of methylene groups is 0) and 0.01g initiator ( Potassium persulfate, first dissolve with a small amount of water), keep stirring for 2 hours to obtain an aqueous solution of zwitterionic modified starch;

[0028] 2) Add 8 g of polyvinyl alcohol to the aqueous solution obtained in step 1), condense and reflux at 90°C for 4 hours, pour the obtained reactant into a mold while hot, and immediately put it into -18°C for freezing for 12 hours, to obtain a white or pale color. The brown hard solid is the hydrate of the modified starch complex gel;

[0029] 3) The hydrate obtained in st...

Embodiment 2

[0031] 1) Put a 250ml three-necked flask into an oil bath pot, add starch (bean starch) and pure water, heat up to 80°C, condense and reflux with magnetic stirring for 2h, add zwitterionic monomer (cationic group is trimethylamine) , the anion group is a sulfonic acid group, the molar ratio of the two groups is 1:1, the two groups are connected by methylene groups, and the number of methylene groups is 1) and an initiator (ceric ammonium nitrate, first used A small amount of water to dissolve), keep stirring for 2h to obtain an aqueous solution of zwitterionic modified starch;

[0032] 2) Add polyvinyl alcohol to the aqueous solution obtained in step 1), condense and reflux at 80°C for 4 hours, pour the obtained reactant into a mold while hot, and immediately put it into -20°C for freezing for 10 hours to obtain white or light brown hard The solid matter is the hydrate of the modified starch composite gel;

[0033] 3) The hydrate obtained in step 2) is placed at room temperat...

Embodiment 3

[0036] 1) Put a 250ml three-necked flask into an oil bath, add starch (consisting of grain starch and corn starch in a mass ratio of 1:1) and pure water, heat up to 90°C, and condense and reflux with magnetic stirring for 1 hour, then add zwitterions Monomer (cationic group is tetramethylammonium chloride, anionic group is phosphoric acid group, the molar ratio of the two groups is 1:1, the two groups are connected by methylene groups, and the number of methylene groups is 2) and an initiator (composed of ammonium persulfate and cerium sulfate in a mass ratio of 2:1), keep stirring for 2h to obtain an aqueous solution of zwitterionic modified starch;

[0037] 2) Add polyvinyl alcohol to the aqueous solution obtained in step 1), condense and reflux at 90°C for 2 hours, pour the obtained reactant into a mold while hot, and immediately put it into -15°C for freezing for 10 hours to obtain white or light brown hard The solid matter is the hydrate of the modified starch composite g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com