Method for determining contents of chitobiose and chitotriose in chitosan oligosaccharides

A technology of oligochitosan and chitobiose, applied in the field of analytical chemistry, can solve the problems of low sensitivity and low UV response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

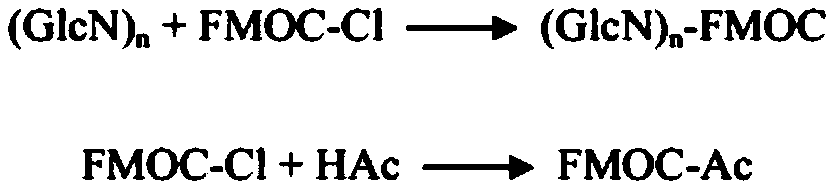

[0017] (1) Fmoc-Cl derivatization reaction

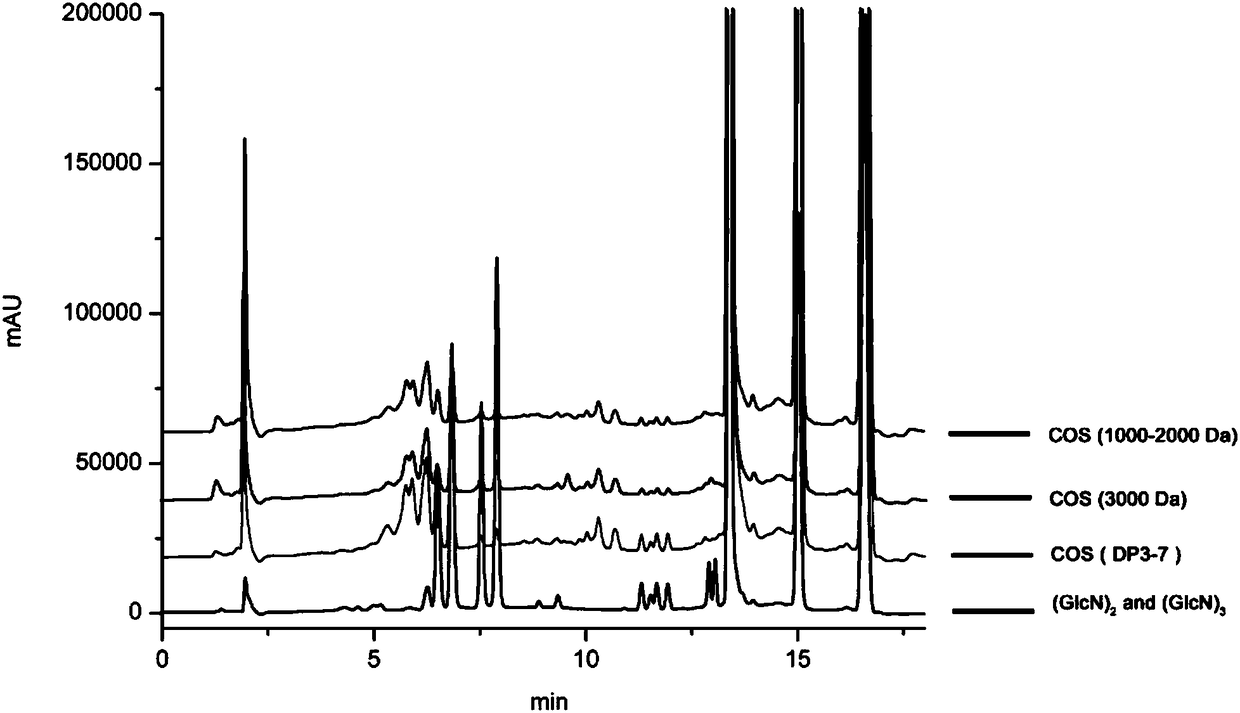

[0018] Weigh an appropriate amount of chitobiose and chitotriose, and add distilled water to prepare control solutions with a concentration of 200 μg / mL and 300 μg / mL, respectively. Three kinds of chitosan oligosaccharide samples were selected, namely oligochitosan with a degree of polymerization of 3-7, oligochitosan with a molecular weight of 1000-2000Da, and oligochitosan with a molecular weight of 3000Da. The chitosan oligosaccharide sample was prepared into a sample solution with a concentration of 0.5 mg / mL with distilled water.

[0019] Weigh an appropriate amount of Fmoc-Cl and dissolve it in acetonitrile to prepare a 500 μg / mL solution, store it in the dark at -4°C, and take it within 24 hours.

[0020] Weigh an appropriate amount of boric acid, add distilled aqueous solution to prepare a 0.25M solution, and then adjust the pH to 8.0 with sodium hydroxide to obtain boric acid buffer. The stop solution was prepared by mixi...

Embodiment 2

[0032] (1) Accuracy experiment

[0033] Add low, medium and high concentrations (0.4%, 20%, 100%) of chitobiose and chitotriose to chitooligosaccharide samples, derivatize the mixed samples with Fmoc-Cl, and use high performance liquid chromatography to determine the chitosan For disaccharide and trisaccharide content, the detected concentration divided by the added concentration is the accuracy. The accuracy results are shown in Table 3, the accuracy of chitobiose is 95.6-107.7%, and the accuracy of chitotriose is 96.5-96.7%.

[0034] Table 3 The accuracy results of the verification of the detection method of the present invention.

[0035]

[0036] (2) Linearity and limit of quantitation experiments

[0037] Chitobiose and chitotriose solutions with concentrations from 0.5 to 500 μg / mL were prepared respectively, and after derivatization by Fmoc-Cl, the peak areas of chitobiose and triose were detected by high performance liquid chromatography; the peak area (y) was Th...

Embodiment 3

[0042] Weigh chitosan oligosaccharide samples with a degree of polymerization of 3-7 and prepare a sample solution with a concentration of 0.5 mg / mL with distilled water.

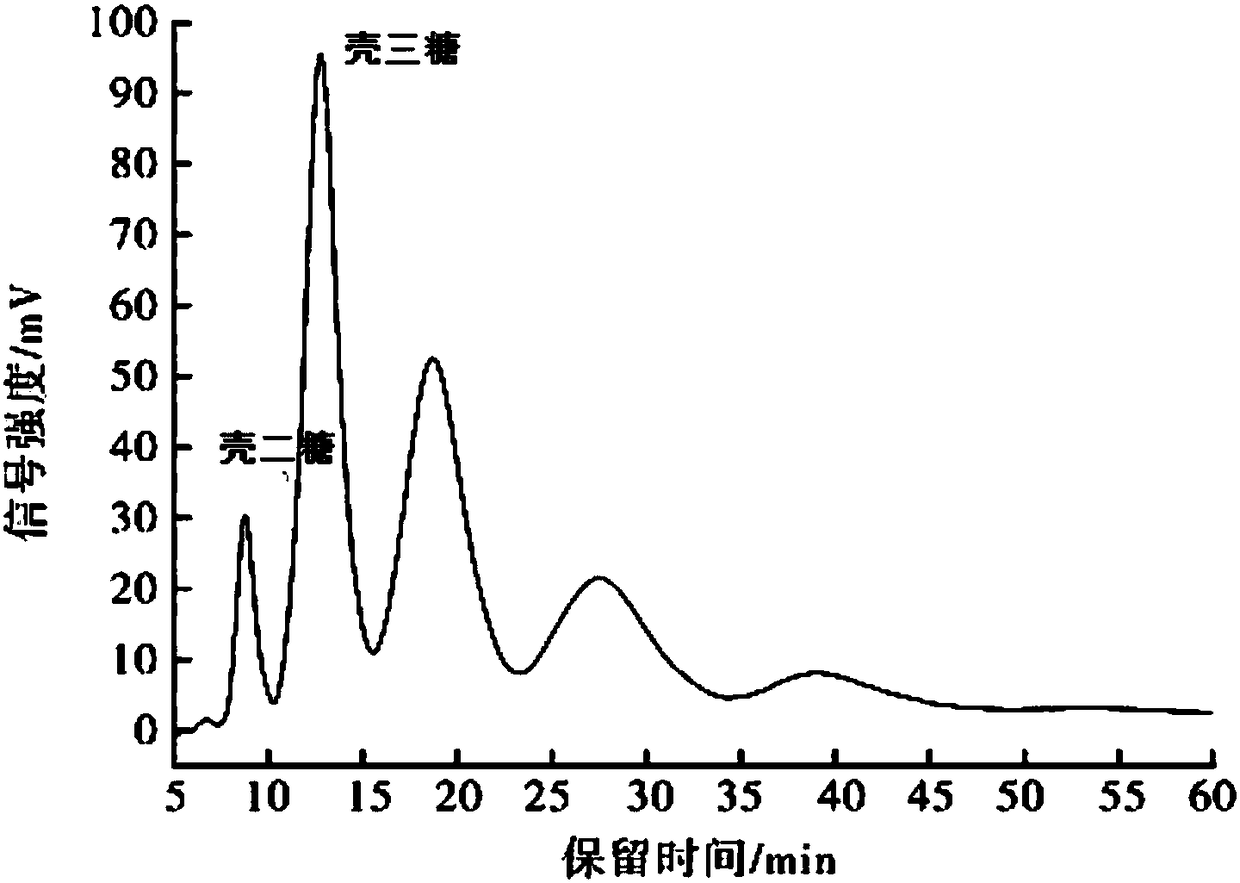

[0043] The chromatographic conditions are:

[0044] Column: Shodex Asahipak NH 2 (4.6mm×250mm, 5μm); mobile phase: acetonitrile-water (75:25); flow rate: 1.0mL / min; column temperature: 25°C; injection volume 25uL; detector: differential refractive index detector

[0045] Chitobiose contrast solution, chitotriose contrast solution, chitosan oligosaccharide sample solution are respectively injected in the high performance liquid chromatograph and analyzed, record chromatogram ( image 3 ).

[0046] Result shows, adopt traditional HPLC method, use differential refraction detector to detect, the separation effect of chitobiose and chitotriose in the chitosan oligosaccharide sample is not as good as the method of the present invention, the separation degree of chitobiose and chitotriose≤ 1.5, only basic separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com