Cobaltous sulfate evaporative crystallization equipment and process

A technology of evaporative crystallization and cobalt sulfate, applied in the direction of cobalt sulfate, solution crystallization, crystallization device general layout, etc., can solve the problems of high equipment investment cost, steam consumption, low production efficiency, etc., and reduce energy consumption, energy consumption, etc. The effect of low consumption and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

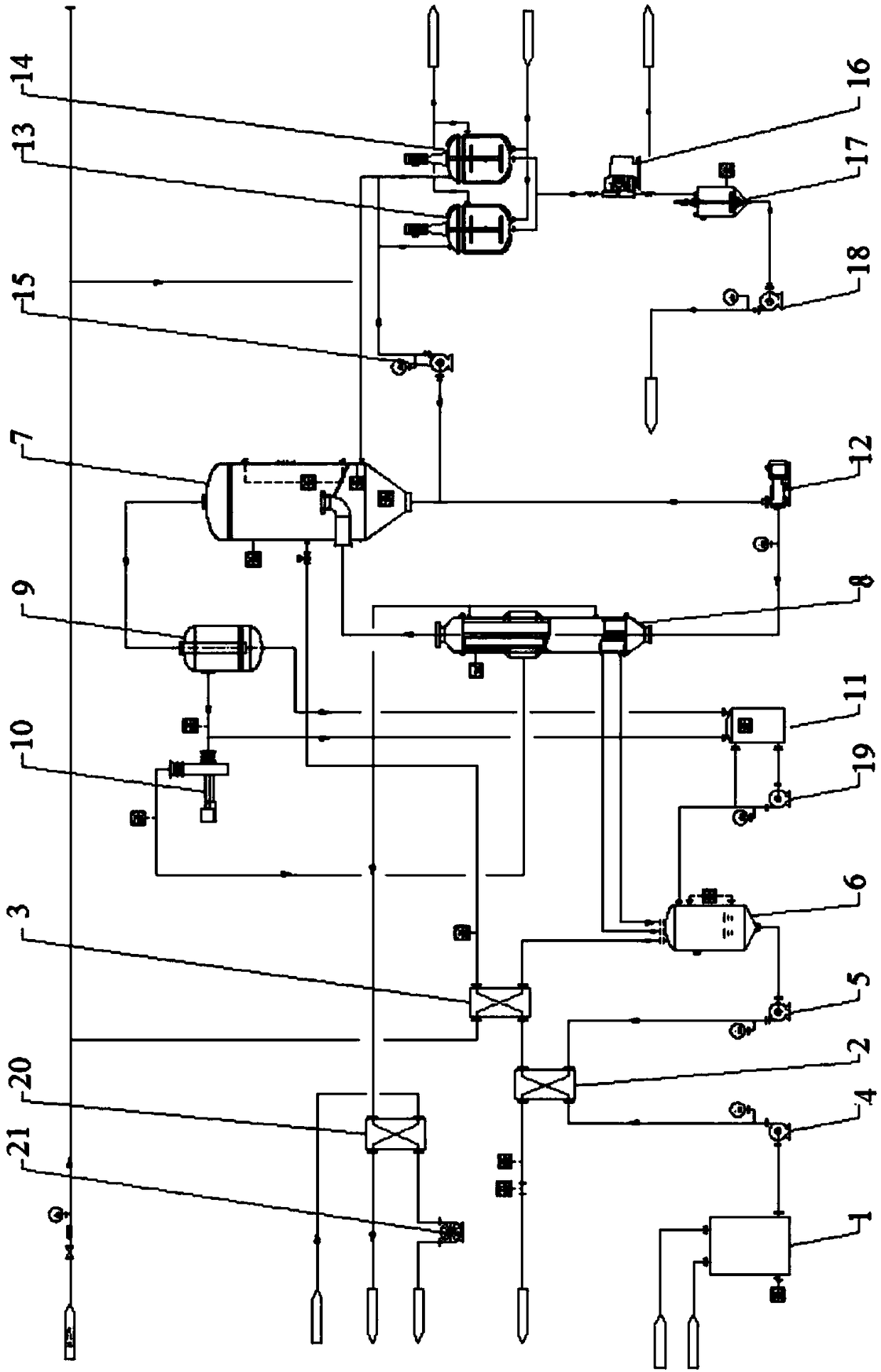

[0027] The present embodiment provides a kind of cobalt sulfate evaporation crystallization equipment, is a kind of equipment that utilizes MVR technology to directly make cobalt sulfate solution heptahydrate cobalt sulfate crystal, described equipment such as figure 1 As shown, it includes the stock solution preheating system, evaporation concentration system, cooling crystallization system and filtration separation system connected in sequence, and also includes the control signal connection with the stock solution preheating system, evaporation concentration system, cooling crystallization system and filtration separation system mechanism, the control mechanism is PLC, and the control mechanism is used to control the automatic processing process of the raw liquid preheating system, evaporation concentration system, cooling crystallization system and filtration separation system, and all input and output signals can be controlled by a computer equipped with PLC control softwar...

Embodiment 2

[0033] This embodiment provides a process for evaporative crystallization using the cobalt sulfate evaporative crystallization equipment described in Example 1, which includes the following steps:

[0034]S1. Stock solution preheating, the cobalt sulfate solution is heated up to the evaporation temperature through the stock solution preheating system, and the cobalt sulfate stock solution stored in the stock solution storage tank 1 is sequentially pumped into the distilled water preheater 2 and the fresh steam preheater 3 by the stock solution pump 4 , heat exchange with the distilled water and fresh steam in each preheater in turn to reach the evaporation temperature of the cobalt sulfate solution of 93 ° C, the distilled water is the secondary steam condensed water obtained by evaporation of the distilled water in the distilled water storage tank 6, the described Fresh steam is saturated steam with a pressure of 0.1MpaG and a temperature of 120°C.

[0035] S2, evaporation an...

experiment example

[0039] The processing capacity situation and the running energy consumption situation of the cobalt acid evaporation crystallization equipment described in Test Example 1, the results are as shown in Table 1:

[0040] Table 1

[0041] serial number

[0042] The above test results show that the evaporation and crystallization equipment described in Example 1 has the advantages of low energy consumption, high output, simple process, small number of equipment, and low construction investment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com