Fe3O4@g-C3N4/RGO composite photocatalyst and preparation method thereof

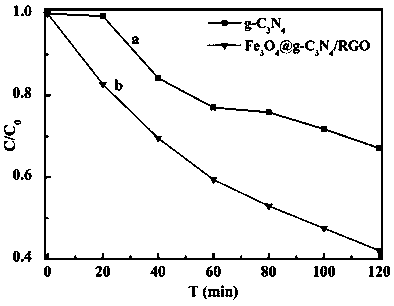

A g-c3n4, catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high photogenerated electron-hole recombination rate, affecting photocatalytic activity and stability, specific Low surface area and other problems, to achieve the effect of improving photocatalytic activity, good magnetism, and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

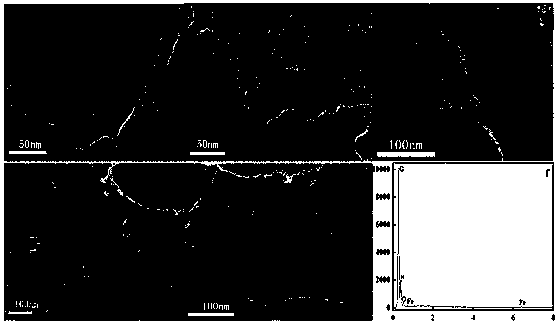

Image

Examples

Embodiment 1

[0018] Fe of the present invention 3 o 4 @g-C 3 N 4 / RGO composite photocatalyst, follow the steps below:

[0019] a. Prepare g-C according to prior art 3 N 4 Powder: Add melamine into the crucible, then transfer it to a high-temperature muffle furnace for thermal polymerization; after the temperature of the muffle furnace cools down to room temperature, take out the crucible, and grind the solid sample in the crucible into powder, then The sample was dried in an oven to obtain g-C 3 N 4 pink;

[0020] b. Change g-C 3 N 4 Disperse the powder in ethylene glycol, keep ultrasonic magnetic stirring in the water bath, then add ferric nitrate nonahydrate, sodium acetate, polyethylene glycol 4000 and polyvinylpyrrolidone to it, continue ultrasonic stirring, and then add redox graphite olefin until the added raw materials are uniformly dispersed or dissolved to obtain a dispersion; the g-C 3 N 4 , ethylene glycol, ferric nitrate nonahydrate, sodium acetate, polyethylene gl...

Embodiment 2

[0024] Fe of the present invention 3 o 4 @g-C 3 N 4 / RGO composite photocatalyst, follow the steps below:

[0025] a. Prepare g-C according to prior art 3 N 4 Powder: Add melamine into the crucible, then transfer it to a high-temperature muffle furnace for thermal polymerization; after the temperature of the muffle furnace cools down to room temperature, take out the crucible, and grind the solid sample in the crucible into powder, then The sample was dried in an oven to obtain g-C 3 N 4 pink;

[0026] b. Change g-C 3 N 4 Disperse the powder in ethylene glycol, keep ultrasonic magnetic stirring in the water bath, then add ferric nitrate nonahydrate, sodium acetate, polyethylene glycol 4000 and polyvinylpyrrolidone to it, continue ultrasonic stirring, and then add redox graphite olefin until the added raw materials are uniformly dispersed or dissolved to obtain a dispersion; the g-C 3 N 4 , ethylene glycol, ferric nitrate nonahydrate, sodium acetate, polyethylene gl...

Embodiment 3

[0030] Fe of the present invention 3 o 4 @g-C 3 N 4 / RGO composite photocatalyst, follow the steps below:

[0031] a. Prepare g-C according to prior art 3 N 4 Powder: Add melamine into the crucible, then transfer it to a high-temperature muffle furnace for thermal polymerization; after the temperature of the muffle furnace cools down to room temperature, take out the crucible, and grind the solid sample in the crucible into powder, then The sample was dried in an oven to obtain g-C 3 N 4 pink;

[0032] b. Change g-C 3 N 4Disperse the powder in ethylene glycol, keep ultrasonic magnetic stirring in the water bath, then add ferric nitrate nonahydrate, sodium acetate, polyethylene glycol 4000 and polyvinylpyrrolidone to it, continue ultrasonic stirring, and then add redox graphite olefin until the added raw materials are uniformly dispersed or dissolved to obtain a dispersion; the g-C 3 N 4 , ethylene glycol, ferric nitrate nonahydrate, sodium acetate, polyethylene gly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com