Fig wine and preparation method thereof

A fig and pectinase technology, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, microorganism-based methods, etc., can solve the problems of lack of market conditions, too many fig pectin substances, and influence on juice extraction, etc. To achieve the effect of promoting appetite, delaying aging, and solving the instability of wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

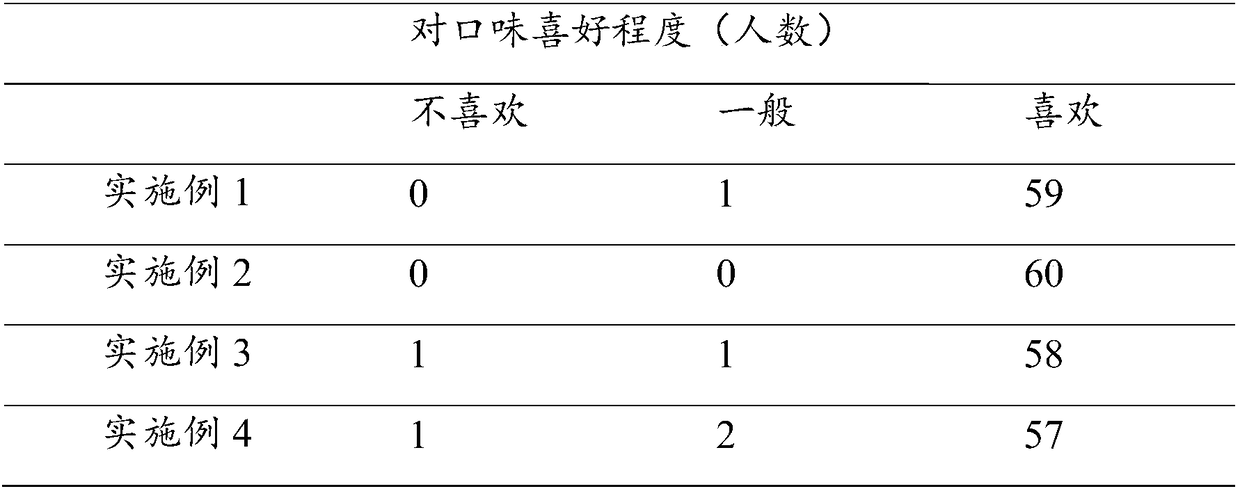

Examples

Embodiment 1

[0084] A kind of production technological process of green fig wine:

[0085] Fig raw wine → blending → filtration → filling, sealing → sterilization → packaging → finished product, the details are as follows.

[0086] 1. Manufacture of original fig wine

[0087] Fig wine production process:

[0088] Fresh figs→selection→cleaning→stalk removal→crushing→enzymolysis→adjusting ingredients→inoculating yeast→fermenting→separating pomace→filtering→fig wine→clarification→filtering→aging.

[0089] Pretreatment: Choose fresh figs with high maturity and no rot as raw materials. After selecting and removing impurities, wash them with clean tap water, remove the stems and use a crusher to break the figs into 3-5mm pieces.

[0090] Enzyme hydrolysis: fig fruit contains a lot of pectin substances, and the pectin substances are not conducive to the separation of slag juice during the winemaking process and affect the clarification of fruit wine. After crushing, add 20wt% pure water, 5wt% ...

Embodiment 2

[0104] A kind of production technological process of green fig wine:

[0105] Fig raw wine→blending→filtering→filling, sealing→sterilization→packaging→finished product.

[0106] 1. Manufacture of original fig wine

[0107] Fig original wine production process is the same as embodiment 1;

[0108] Pretreatment: Choose fresh figs with high maturity and no rot as raw materials. After selecting and removing impurities, wash them with clean tap water, remove the stems and use a crusher to break the figs into 3-5mm pieces.

[0109] Enzymolysis: after crushing, add 25wt% pure water, 6wt% 60%vol deodorized edible alcohol and 0.4wt% edible citric acid to the fig puree. After adding alcohol and edible citric acid, add 0.25g food-grade pectinase (100,000 units / gram) per kilogram of pulp to it, and enzymolyze it for 2.5 hours at normal temperature.

[0110] Adjustment composition: with embodiment 1.

[0111] Fermentation: active dry yeast (fruit wine yeast) is used for the starter, an...

Embodiment 3

[0123] A production process of green fig wine:

[0124] Fig wine → preparation → filtration → filling, sealing → sterilization → packaging → finished product

[0125] 1. Manufacture of fig wine

[0126] The production process flow of fig original wine is the same as in Example 1;

[0127] Pretreatment: Choose fresh figs with high maturity and no rot as raw materials. After selecting and cleaning with clean tap water, remove the stems and use a crusher to break the figs into pieces of 3-5mm.

[0128] Enzymatic hydrolysis: after crushing, 27wt% pure water, 5wt% 60%vol deodorized edible alcohol and 0.2wt% edible citric acid are added to the fig puree. After adding alcohol and edible citric acid, add 0.25g of food-grade pectinase (100,000 units / g) per kilogram of pulp, and enzymolysis at room temperature for 2 hours.

[0129] Adjusted components: the same as in Example 1.

[0130] Fermentation: Active dry yeast (fruit wine yeast) is used as the starter, and the dosage is 0.25g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com