Three-dimensional cobaltous sulfide oxygen evolution electrode preparation method based on electrodepositing technology and electrode prepared through method

An oxygen evolution electrode, cobalt sulfide technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of inability to realize three-dimensional electrode construction, high energy consumption, achieve excellent catalytic performance and stability, simple preparation method, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A three-dimensional cobalt sulfide oxygen precipitation electrode based on electrodeposition technology and a preparation method thereof, comprising the following steps:

[0032] 1) Cobalt salt and thiocyanate are dissolved in water, and mixed solution is prepared; the cobalt salt is at least one of cobalt chloride, cobalt nitrate, cobalt sulfate or cobalt acetate; the thiocyanate is sulfur At least one of sodium cyanate, potassium thiocyanate or ammonium thiocyanate; the concentration of cobalt salt is 0.01-0.50 mol / L, and the concentration of thiocyanate is 0.04-2.0 mol / L.

[0033] 2) The aqueous solution prepared in step 1) is used as an electrolyte, and the conductive substrate is used as an electrode, and cobalt sulfide material is grown on the conductive substrate by electrodeposition technology. The conductive substrate is nickel mesh, titanium mesh, titanium sheet, copper sheet or stainless steel sheet, with an area of 0.2×0.2cm 2 ~1.0×1.0cm 2 . The electro...

Embodiment 1

[0036] The three-dimensional cobalt sulfide oxygen precipitation electrode based on the electrodeposition technology of this embodiment and its preparation method comprise the following steps:

[0037] 1) Dissolving cobalt sulfate and potassium thiocyanate in water, the concentrations of cobalt sulfate and potassium thiocyanate are respectively 0.05mol / L and 0.2mol / L;

[0038] 2) Use the aqueous solution prepared in step 1) as the electrolyte solution, and use 0.5×0.5cm 2 The titanium sheet was used as the conductive substrate, and the cobalt sulfide material was grown on the conductive substrate by the chronoamperometry method, and the control potential was -0.95V ( 参照 saturated calomel electrode), the time is 1200s;

[0039] 3) The three-dimensional cobalt sulfide oxygen precipitation electrode prepared in step 2) was washed 10 times with pure water, and then dried at room temperature for 8 hours.

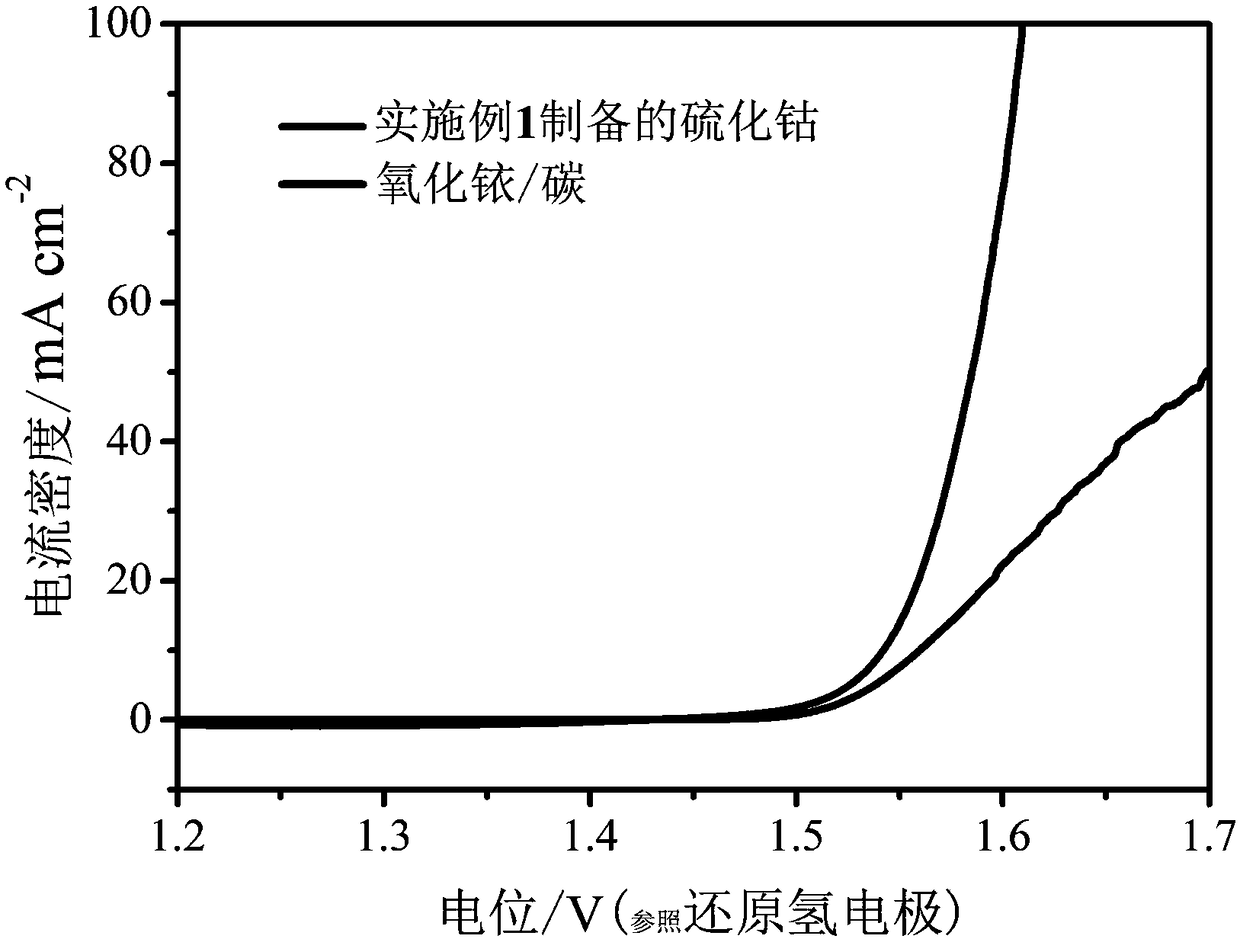

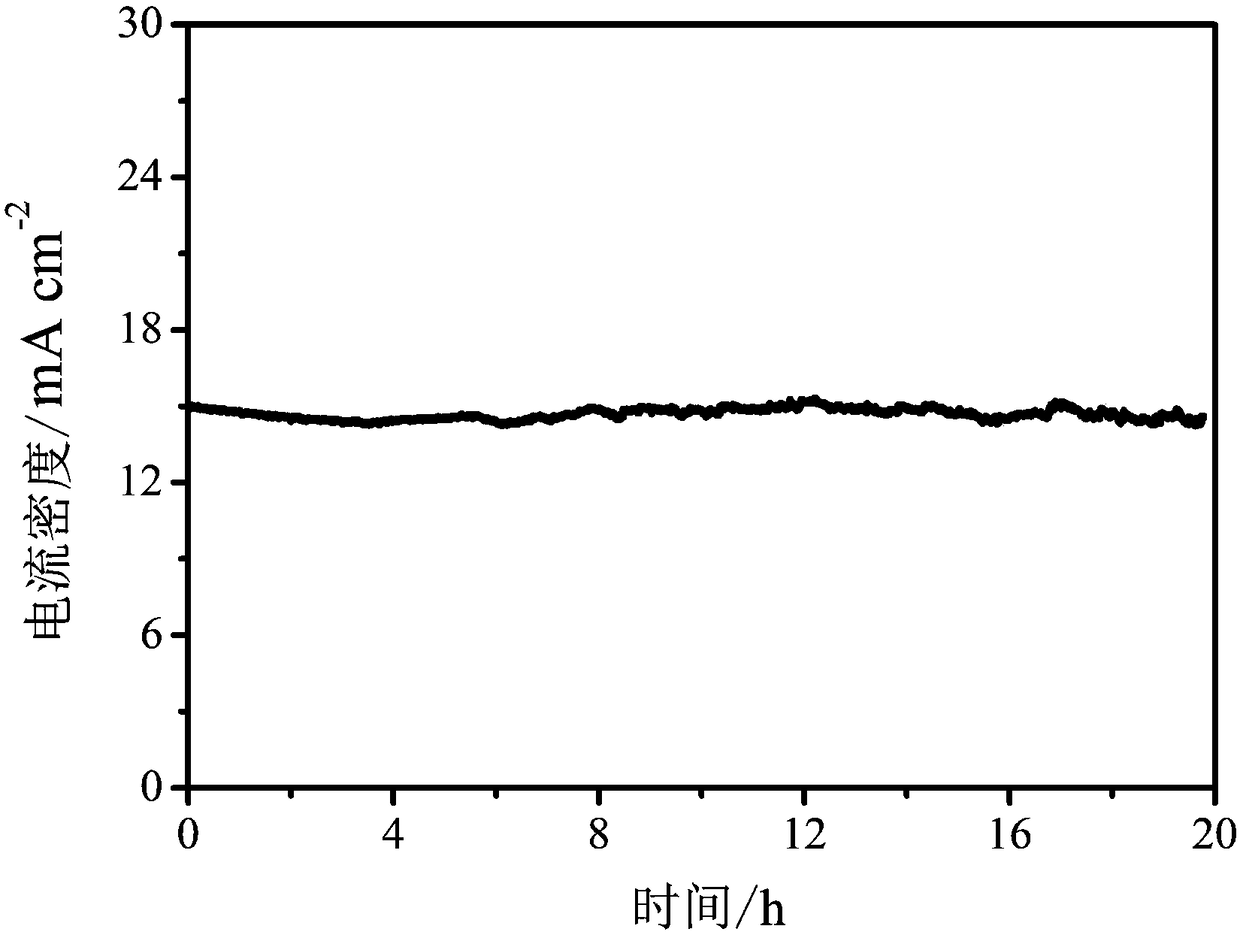

[0040] figure 1 The scanning electron microscope image of the three-dimen...

Embodiment 2

[0045] The three-dimensional cobalt sulfide oxygen precipitation electrode based on the electrodeposition technology of this embodiment and its preparation method comprise the following steps:

[0046]1) Cobalt chloride and sodium thiocyanate are dissolved in water, and the concentrations of cobalt chloride and sodium thiocyanate are respectively 0.03mol / L and 0.12mol / L;

[0047] 2) Use the aqueous solution prepared in step 1) as the electrolyte, and use 0.3×0.3cm 2 The nickel mesh is used as the conductive substrate, and the cobalt sulfide material is grown on the conductive substrate by the chronopotentiometry method, and the current density is controlled at 1.5mA / cm 2 , the time is 600s;

[0048] 3) The three-dimensional cobalt sulfide oxygen precipitation electrode prepared in step 2) was washed 5 times with pure water, and then dried at room temperature for 20 hours.

[0049] Figure 4 The scanning electron microscope image of the three-dimensional cobalt sulfide oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com