Preparation method and application of leaf-shaped cobalt phosphate nanosheet

A technology of cobalt phosphate nano and cobalt phosphate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of less transition metal phosphide materials, and achieve low cost, convenient mass production, The effect of mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

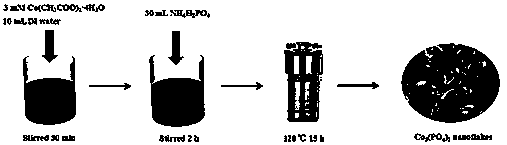

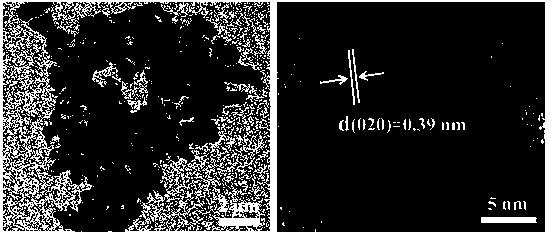

[0041] This embodiment provides a method for preparing cobalt phosphate nanosheets in the shape of leaves, such as figure 1 As shown, follow the steps below:

[0042] Step 1: Preparation of Co(CH 3 COO) 2 4H 2 O solution: Measure 35 ml of 0.3 mol / L Co(CH 3 COO) 2 4H 2 O solution was dispersed in 15 ml ethylene glycol solvent, stirred at room temperature, and Co(CH 3 COO) 2 4H 2 O is fully dissolved in the solvent to produce Co(CH 3 COO) 2 4H 2 O solution;

[0043] Step 2: Preparation of cobalt phosphate precursor: to the above Co(CH 3 COO) 2 4H 2 Add 35 ml to the O solution, the concentration is 0.2mol / L NH 4 h 2 PO 4 solution, and stir evenly to obtain a cobalt phosphate precursor;

[0044] Step 3: Hydrothermal reaction: the cobalt phosphate precursor solution was placed in a 100 ml Teflon-lined stainless steel autoclave, and reacted at a constant temperature of 120°C for 15 hours. After centrifugation, the obtained solid was precipitated with Alternately w...

Embodiment 2

[0049] Such as figure 1 As shown, the present embodiment provides a method for preparing leaf-shaped cobalt phosphate nanosheets, which is carried out according to the following steps:

[0050] Step 1: Preparation of Co(CH 3 COO) 2 4H 2 O solution: Measure 30 ml of 0.3 mol / L Co(CH 3 COO) 2 4H 2 The O solution was dispersed in 10 ml ethylene glycol solvent, stirred at room temperature, and the Co(CH 3 COO) 2 4H 2 O is fully dissolved in the solvent to produce Co(CH 3 COO) 2 4H 2 O solution;

[0051] Step 2: Preparation of cobalt phosphate precursor: to the above Co(CH 3 COO) 2 4H 2 Add 35 ml to the O solution, the concentration is 0.2mol / L NH 4 h 2 PO 4 solution, and stir evenly to obtain a cobalt phosphate precursor;

[0052] Step 3: Hydrothermal reaction: The cobalt phosphate precursor solution was placed in a 100 ml polytetrafluoroethylene-lined reaction kettle, and reacted at a constant temperature of 110°C for 12 hours. After centrifugation, the obtained ...

Embodiment 3

[0055] This example provides a three-electrode system made of the leaf-shaped cobalt phosphate nanosheets prepared in Example 1, and the electrochemical performance test of the cobalt phosphate nanosheet three-electrode system is prepared by the following sequential steps:

[0056] (1) According to the mass ratio of 80:5:15, weigh cobalt phosphate nanosheets, polytetrafluoroethylene, and acetylene carbon black and place them on a nickel foam substrate of 1 square centimeter, and then use a thin film under an applied pressure of 7 MPa The foil is pressed tightly to obtain the cobalt phosphate electrode material loaded on the nickel foam, and the cobalt phosphate nanosheet electrode material is used as a capacitor electrode sheet;

[0057] (2) The cobalt phosphate / polytetrafluoroethylene / acetylene carbon black flexible symmetrical supercapacitor electrode material obtained above was assembled into a three-electrode system, in which a certain proportion of cobalt phosphate / polytet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com