Compound Pt/TiO(2-x)Nx catalyst with performance of preparing hydrogen through water decomposition by visible light as well as preparation and application of compound Pt/TiO(2-x)Nx catalyst

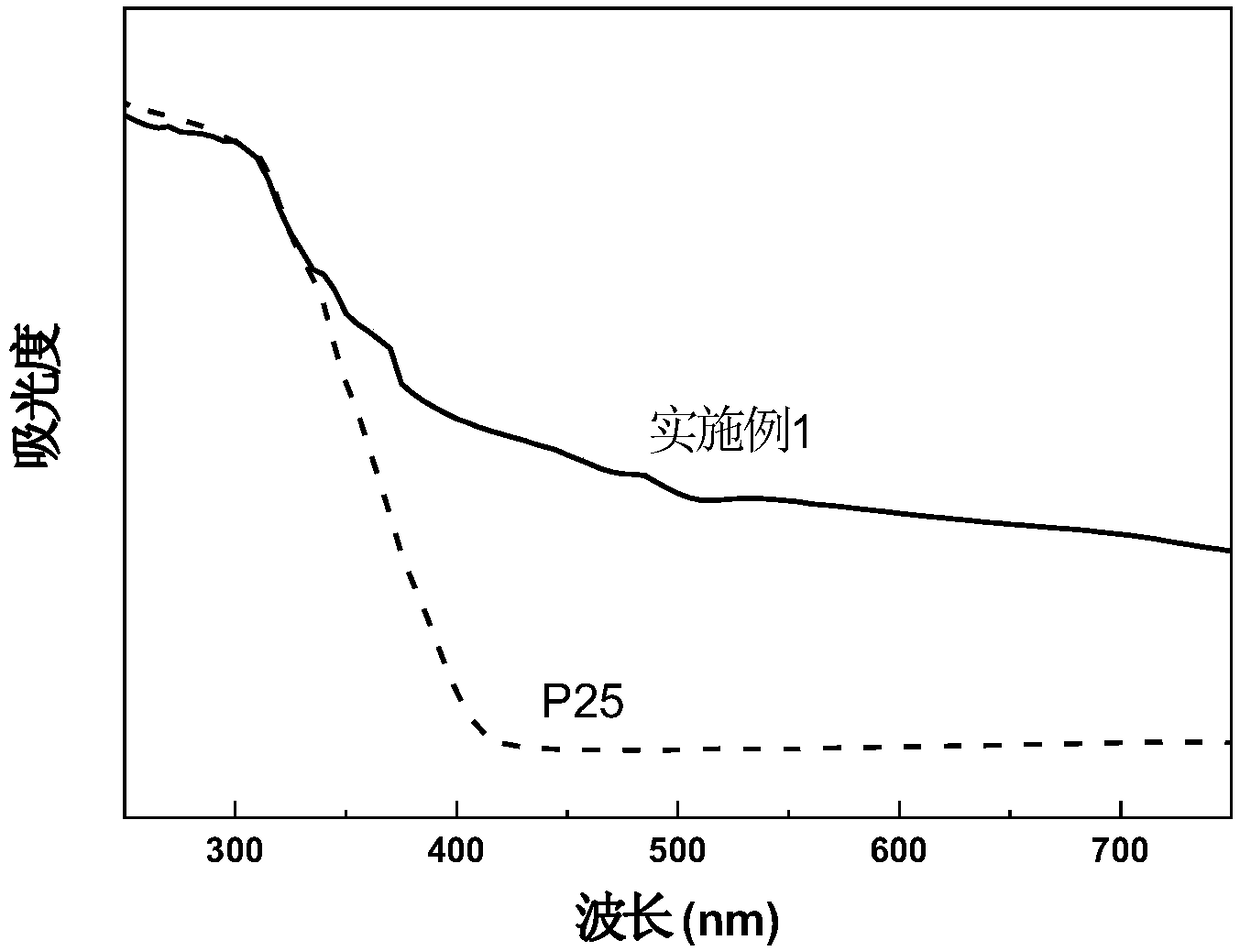

A tio2-xnx and water-splitting technology, which is applied to the visible light photocatalyst and its preparation and application fields, can solve the problems of only absorbing ultraviolet light and cannot be used, and achieves the effects of improving the photon quantum efficiency, uniform composition and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

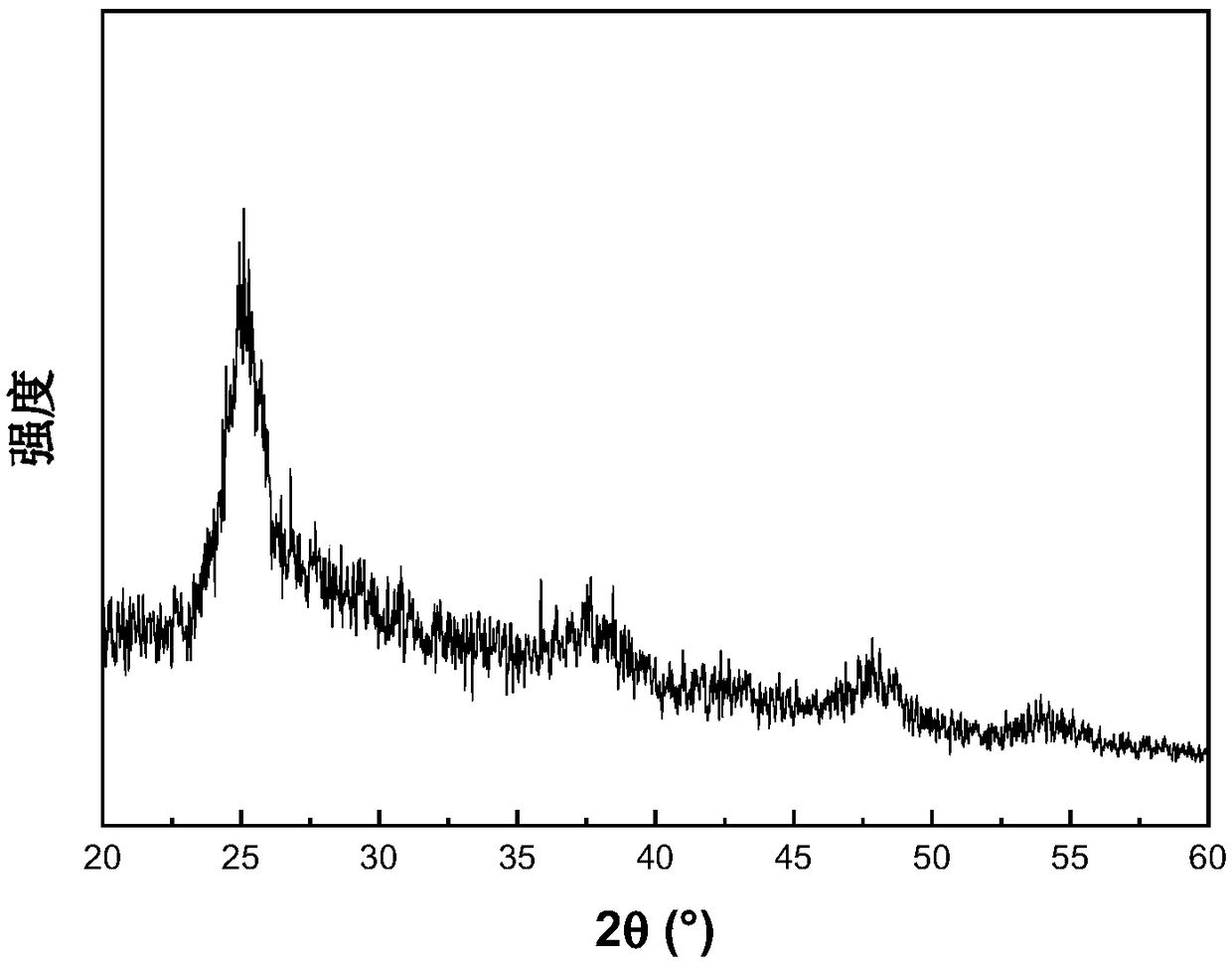

[0034](1) Add 4.3ml of 0.1M nitric acid in ethanol to 90ml of tetraethyl orthosilicate ethanol solution with a volume ratio of 1:1, reflux at 70°C for 2 hours, and cool to room temperature. Take 90ml of the above solution, then add 44ml of butyl titanate ethanol solution with a volume ratio of 1:1 and stir. Then gradually add 9.2ml of 0.1M nitric acid ethanol solution, so that the amount of water is twice the sum of the amounts of titanium and silicon. Stand still until a gel is formed to obtain a titanium-silicon composite oxide gel, which is dried at 110°C, crushed, sieved, and calcined at 600°C for two hours. Weigh 2 grams after cooling, place in a tube furnace, flow rate is 400 ml / min in flowing ammonia, nitriding at 900 degrees Celsius for 5 hours, and cool to room temperature in nitrogen protection. Then placed in 2.0M sodium hydroxide solution, washed at 70 degrees Celsius for 12 hours, washed with water until neutral, and then dried at 110 degrees Celsius to obtain gr...

Embodiment 2

[0039] (1) Add 4.3ml of 0.1M nitric acid in ethanol to 90ml of tetraethyl orthosilicate in ethanol with a volume ratio of 1:1, reflux at 70°C for 2 hours, and cool to room temperature. Take 60ml of the above solution, then add 44ml of butyl titanate ethanol solution with a volume ratio of 1:1 and stir. Then gradually add 9.2ml of 0.1M nitric acid ethanol solution, so that the amount of water is twice the sum of the amounts of titanium and silicon. Stand still until a gel is formed to obtain a titanium-silicon composite oxide gel, which is dried at 110°C, crushed, sieved, and calcined at 600°C for two hours. Weigh 2 grams after cooling, place in a tube furnace, flow rate is 400 ml / min in flowing ammonia, nitriding at 900 degrees Celsius for 5 hours, and cool to room temperature in nitrogen protection. Then placed in 2.0M sodium hydroxide solution, washed at 70 degrees Celsius for 12 hours, washed with water until neutral, and then dried at 110 degrees Celsius to obtain gray po...

Embodiment 3

[0045] (1) Add 4.3ml of 0.1M nitric acid in ethanol to 90ml of tetraethyl orthosilicate in ethanol with a volume ratio of 1:1, reflux at 70°C for 2 hours, and cool to room temperature. Take 30ml of the above solution, then add 44ml of butyl titanate ethanol solution with a volume ratio of 1:1 and stir. Then gradually add 9.2ml of 0.1M nitric acid ethanol solution, so that the amount of water is twice the sum of the amounts of titanium and silicon. Stand still until a gel is formed to obtain a titanium-silicon composite oxide gel, which is dried at 110°C, crushed, sieved, and calcined at 600°C for two hours. Weigh 2 grams after cooling, place in a tube furnace, flow rate is 400 ml / min in flowing ammonia, nitriding at 900 degrees Celsius for 5 hours, and cool to room temperature in nitrogen protection. Then placed in 2.0M sodium hydroxide solution, washed at 70 degrees Celsius for 12 hours, washed with water until neutral, and then dried at 110 degrees Celsius to obtain gray po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com