Outer wall outer heat-preservation system with gel glass bead heat-preservation plate

A technology for external thermal insulation and thermal insulation boards for external walls, applied in the field of building wall systems, can solve the problem that the thermal insulation layer is no longer applicable, and achieve the effects of smooth surface, high flame retardant grade and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation process of acrylic acid emulsion film former is as follows:

[0033] (1) Pre-emulsification: Add 100 parts of water, 3 parts of emulsifier, and 5 parts of acrylamide into the reaction bottle, add 5 parts of styrene, 10 parts of butyl acrylate, and 10 parts of acrylic acid under stirring conditions to prepare non-layered white pre-emulsion;

[0034] (2) Polymerization: Add 100 parts of water, 1 part of initiator, 10 parts of pre-emulsion and 5 parts of ammonium persulfate aqueous solution into the reaction bottle, heat up to 65°C, keep warm for 1 hour, and neutralize with ammonia water to pH=7.5~8 in between.

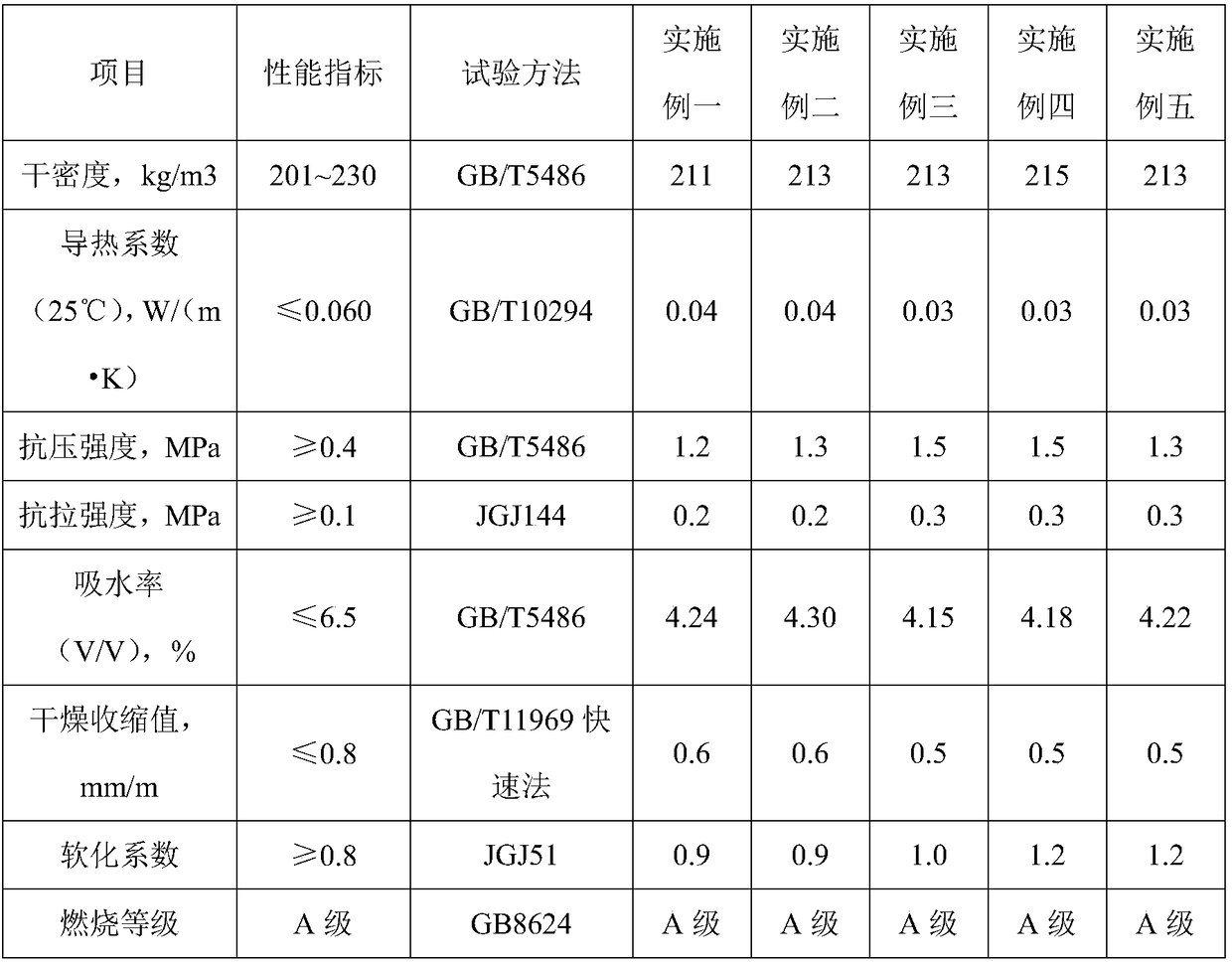

Embodiment 1

[0036] A preparation method of a gel glass bead insulation board, comprising the steps of:

[0037] (1) Preparation of active silica gel binder: Weigh 80 parts of diatomite slurry, 30 parts of cement clinker powder, 10 parts of calcium formate, 5 parts of polyborosiloxane and 1 part of KH-550 for high-speed mixing , wait for it to mix evenly, set aside;

[0038] (2) Preparation of modified powder curing agent: a, 20 parts of powder curing agent, 50 parts of high-strength Portland cement, 1 part of active silica gel binder, 2 parts of nano-airgel, and 0.2 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material to form a modified powder curing agent;

[0039] (3) Material preparation: 100 parts of expanded perlite, 10 parts of inorganic silicon gel, 5 parts of cement-based binder, 20 parts of modified powder curing agent, 15 parts of nano-airgel and 5 parts of anti-seepage bonding material ;

...

Embodiment 2

[0042] A preparation method of a gel glass bead insulation board, comprising the steps of:

[0043] (1) Preparation of active silica gel binder: Weigh 85 parts of diatomite slurry, 30 parts of cement clinker powder, 12 parts of calcium formate, 5 parts of polyborosiloxane and 1 part of KH-550 for high-speed mixing , wait for it to mix evenly, set aside;

[0044] (2) Preparation of modified powder curing agent: a, 20 parts of powder curing agent, 50 parts of high-strength Portland cement, 1.2 parts of active silica gel binder, 2.2 parts of nano-airgel, and 0.3 parts of polypropylene fiber Parts are uniformly mixed; b, the mixture in a is blended with 20 parts of anti-seepage water bonding material to form a modified powder curing agent;

[0045] (3) Material preparation: 105 parts of expanded perlite, 12 parts of inorganic silica gel, 5 parts of cement-based binder, 22 parts of modified powder curing agent, 15 parts of nano-airgel and 6 parts of anti-seepage bonding material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com