Treatment method and treatment system for desulfurization wastewater

A desulfurization wastewater and treatment method technology, which is applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high cost of chemicals, complicated operation, long process flow, etc., and achieve a small footprint , Improve the recovery rate and reduce the effect of project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

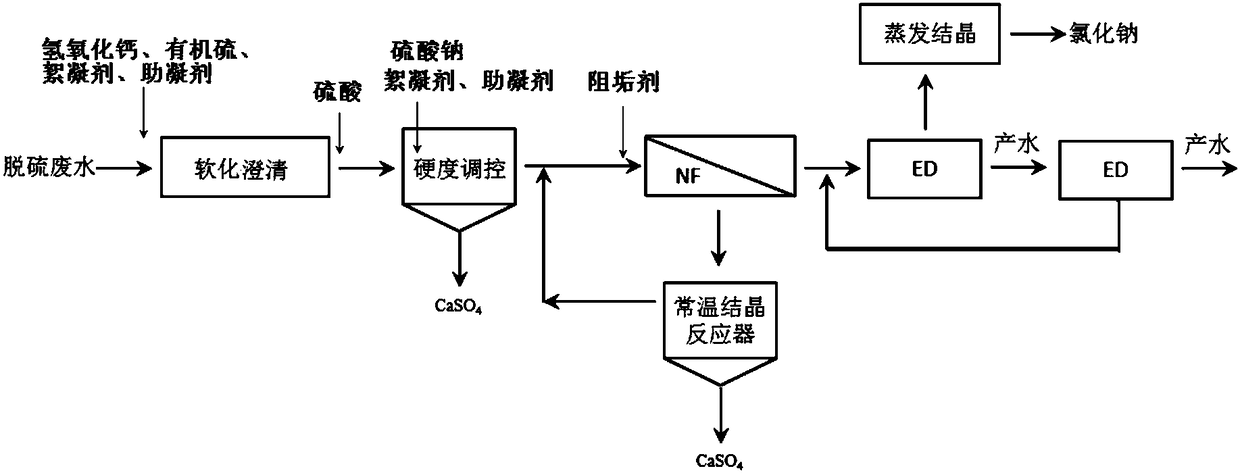

[0099] combine figure 1 , this embodiment is used to illustrate the treatment method of desulfurization wastewater of the present invention.

[0100] The softening clarification treatment unit that uses in the present embodiment comprises that volume is 15m 3 The reaction tank and volume is 20m 3 The clarification tank; the hardness control treatment unit is a hardness control reaction pool, including a volume of 20m 3 The reaction zone and volume is 20m 3 The settling area; the nanofiltration separation unit is a first-stage two-stage nanofiltration system consisting of 6 membrane shells and 4 GE DK 8040F30 nanofiltration membrane elements connected in series; the normal temperature crystallization unit includes a volume with an insulating layer 20.0m 3 The stainless steel container and centrifugal separation device; the first electrodialysis separation unit contains a total membrane area of 80m 2 The three-stage hydraulic series electrodialysis membrane stack and the ...

Embodiment 2

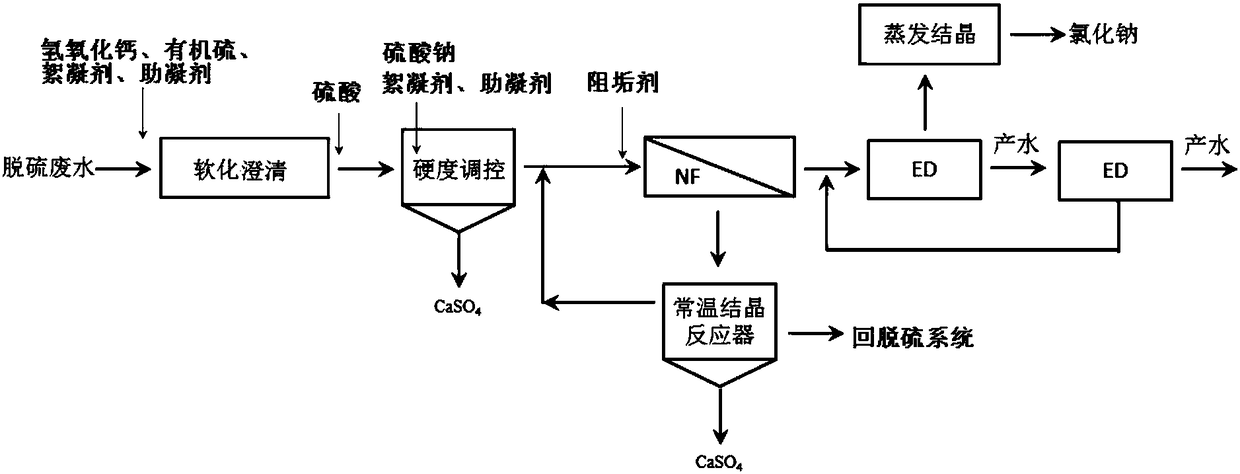

[0113] combine figure 2 , this embodiment is used to illustrate the treatment method of desulfurization wastewater of the present invention.

[0114] The treatment system of the desulfurization waste water of the present embodiment is the same as embodiment 1, and the specific technological process is as follows:

[0115] (1) Adding mass concentration in the power plant desulfurization wastewater shown in Table 2 of 22T / h in the reaction tank is 5% Ca(OH) 2 , adjust the pH of the wastewater to 11.1, and add 60mg / L organic sulfur TMT-15, 18mg / L flocculant polyferric chloride and 10mg / L coagulant polyacrylamide, react for 18min, and the reaction in the reaction tank The material was transported to the clarification tank for settlement for 60 minutes to obtain 22T / h softened and clarified effluent, wherein the concentration of magnesium ions in the softened and clarified effluent was 12.8 mg / L, and the molar ratio of calcium ions to sulfate was 128:13;

[0116] (2) Adding sulf...

Embodiment 3

[0127] combine figure 2 , this embodiment is used to illustrate the treatment method of desulfurization wastewater of the present invention.

[0128] The treatment system of the desulfurization waste water of the present embodiment is the same as embodiment 1, and the specific technological process is as follows:

[0129] (1) Adding mass concentration in the power plant desulfurization wastewater shown in Table 3 of 22T / h in the reaction tank is 5% Ca(OH) 2 , adjust the pH of the wastewater to 11.5, and add 50mg / L organic sulfur TMT-15, 20mg / L flocculant polyaluminum sulfate and 5mg / L coagulant polyacrylamide, react for 45min, and remove the reactants in the reaction tank Transport it to the clarification tank for 45 minutes to settle to obtain 22T / h softened and clarified effluent, wherein the concentration of magnesium ions in the softened and clarified effluent is 8.73mg / L, and the molar ratio of calcium ions to sulfate is 142:11;

[0130] (2) Adding sulfuric acid with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com