High-performance lithium nickel cobalt aluminate positive electrode material and preparation method thereof

A technology of nickel-cobalt lithium aluminate and cathode material, which is applied in battery electrodes, structural parts, electrical components, etc., can solve the problems such as limitations in the application of nickel-cobalt lithium aluminate cathode materials, impact on cycle stability, and failure to achieve good results. , to achieve the effect of improving electrochemical performance, particle uniformity, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

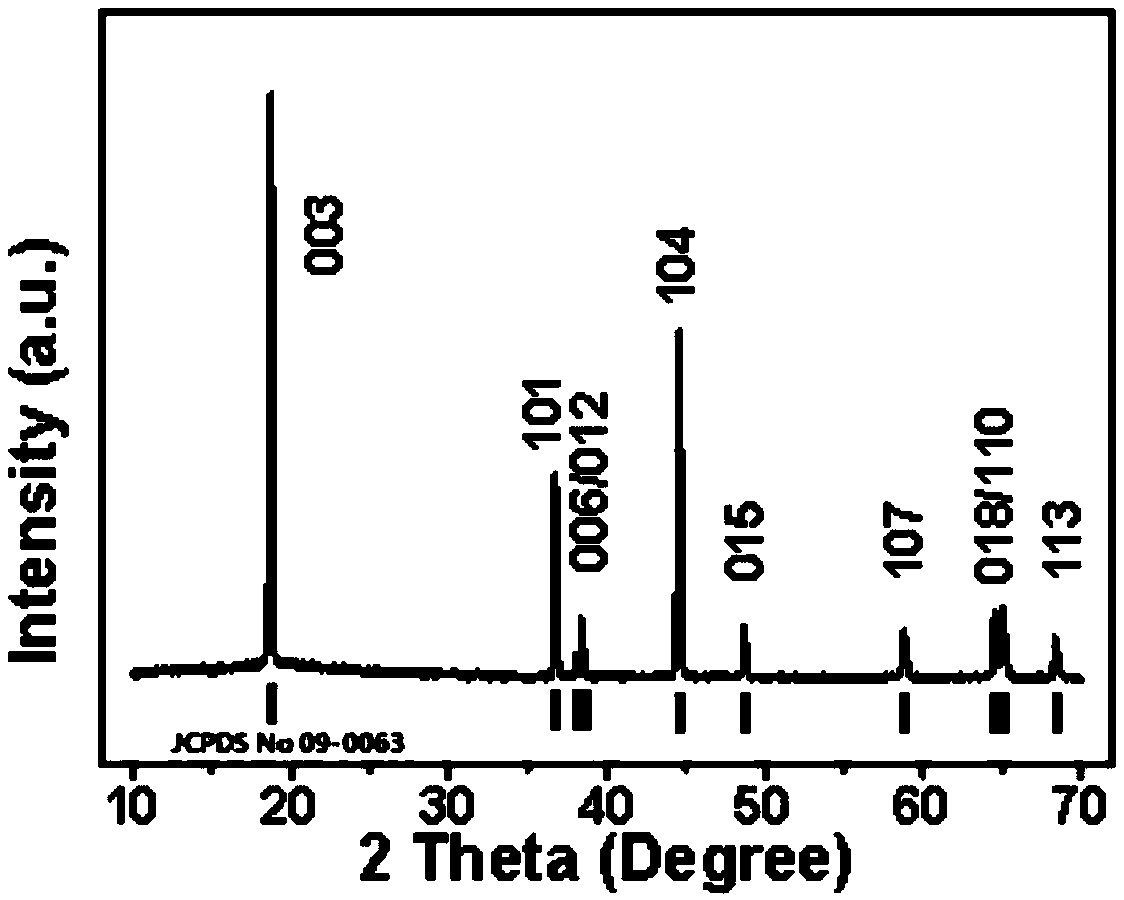

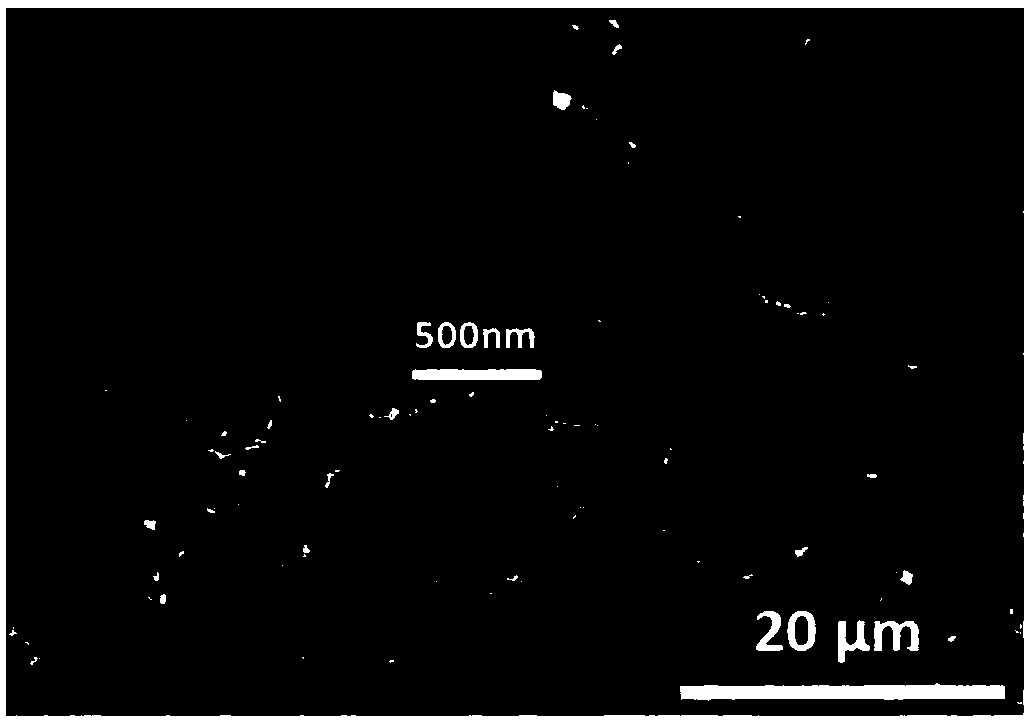

[0033] In this example, the preparation steps for preparing high-performance nickel-cobalt lithium aluminate cathode material are as follows:

[0034] (1) Preparation of Nickel Cobalt Aluminum Hydroxide Precursor

[0035] First nickel sulfate, cobalt sulfate and aluminum sulfate are dissolved in deionized water according to the nickel, cobalt, aluminum mol ratio of 80:15:5 to form a salt solution that the total concentration of nickel sulfate, cobalt sulfate and aluminum sulfate is 2mol / L. Solution (feeding rate is 200min in empty time), 4mol / L ammonia water and 2mol / L sodium hydroxide solution use 3 strands in the peristaltic pump to add the raw materials to the 50 ° C reaction vessel with a stirring blade, under stirring conditions Carry out precipitation reaction, the pH of reaction system is maintained at 11.5 by controlling ammoniacal liquor and sodium hydroxide solution feed rate in the reaction process; 800min, adjust the feed rate of ammonia water and sodium hydroxide...

Embodiment 2

[0041] In this example, the preparation steps for preparing high-performance nickel-cobalt lithium aluminate cathode material are as follows:

[0042] (1) Preparation of Nickel Cobalt Aluminum Hydroxide Precursor

[0043] First nickel nitrate, cobalt nitrate and aluminum nitrate are dissolved in deionized water according to the nickel, cobalt, aluminum mol ratio of 90:7:3 to form nickel nitrate, cobalt nitrate and aluminum nitrate total concentration is a salt solution of 1mol / L, the salt Solution (feeding rate is 100min in empty time), 2mol / L ammonia water and 2mol / L sodium hydroxide solution use 3 strands in a peristaltic pump to add the raw materials to a 60°C reaction vessel with a stirring paddle, under stirring conditions Carry out precipitation reaction, the pH of reaction system is maintained as 11.3 by controlling ammoniacal liquor and sodium hydroxide solution feed rate in the reaction process; 600min, adjust the feeding rate of ammonia water and sodium hydroxide so...

Embodiment 3

[0049] In this example, the preparation steps for preparing high-performance nickel-cobalt lithium aluminate cathode material are as follows:

[0050] (1) Preparation of Nickel Cobalt Aluminum Hydroxide Precursor

[0051] First, nickel chloride, cobalt chloride and aluminum chloride are dissolved in deionized water according to the nickel, cobalt and aluminum molar ratio of 80:15:5 to form a total concentration of nickel chloride, cobalt chloride and aluminum chloride of 4mol / L The salt solution, the salt solution (feed rate is 200min in empty time), 4mol / L ammonia water and 8mol / L sodium hydroxide solution are added to the 50 ℃ reaction vessel with a stirring paddle in 3 stocks with a peristaltic pump In, carry out precipitation reaction under agitation condition, the pH of reaction system is maintained as 11.5 by controlling ammoniacal liquor and sodium hydroxide solution feeding rate in the reaction process; The feed rate is 800 minutes in empty time, and adjust the feed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com