A kind of dissimilar metal electron beam welding method of titanium alloy and Kovar alloy

A technology of electron beam welding and dissimilar metals, which is applied in the field of electron beam welding of dissimilar metals between titanium alloys and Kovar alloys, and in the field of welding between titanium alloys and Kovar alloys, and can solve the problems of poor welding performance between titanium alloys and Kovar alloys. , to achieve the effects of preventing sample deformation, improving mechanical properties, and requiring less workpiece shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Grind and polish the surface of TC4 titanium alloy and 4J29 Kovar alloy to be welded to make the roughness Ra≤1.0μm; pickle the polished sample, and use a mixed solution of hydrofluoric acid and nitric acid to remove the titanium alloy. Surface oxide film; and using H 2 SO 4 solution to remove the oxide film on the surface of copper foil. Then, the copper foil and niobium foil were put into acetone and ultrasonically cleaned for 15 minutes, the surface to be welded was wiped with alcohol, and dried with cold air to obtain cleaned titanium alloy, kovar alloy, copper foil and niobium foil.

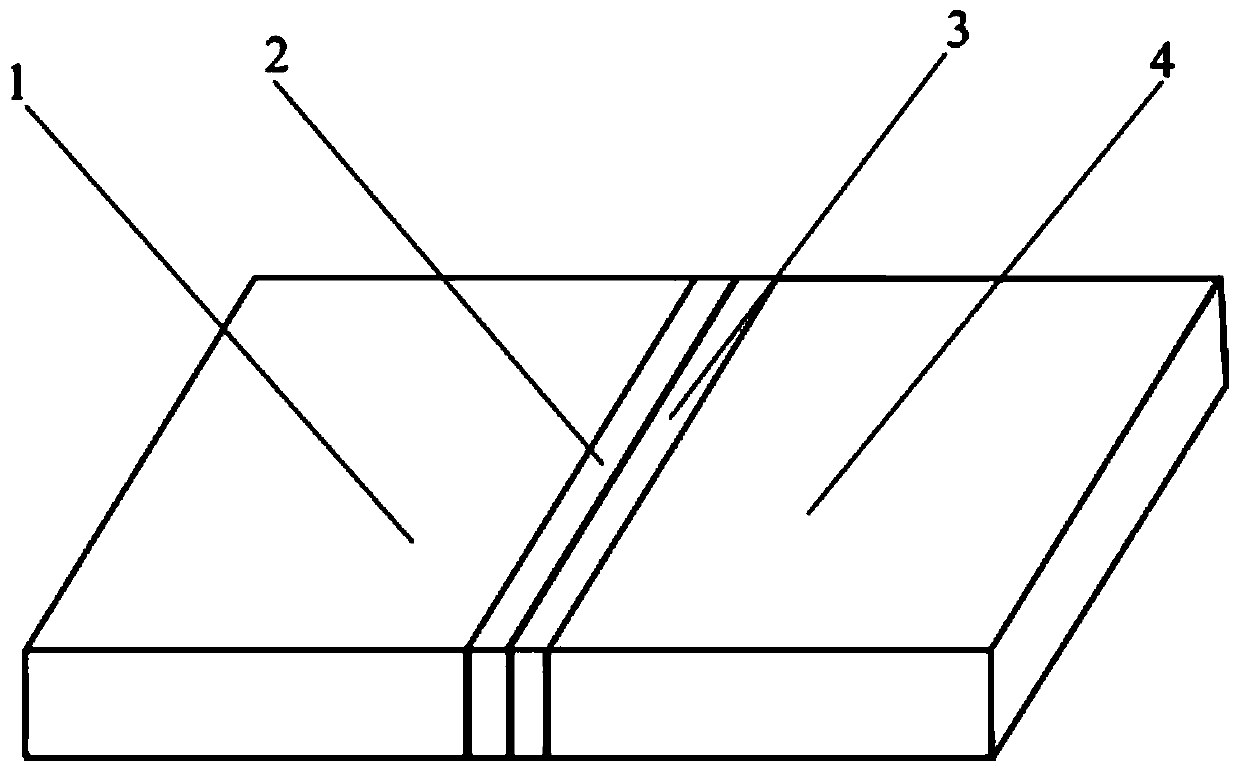

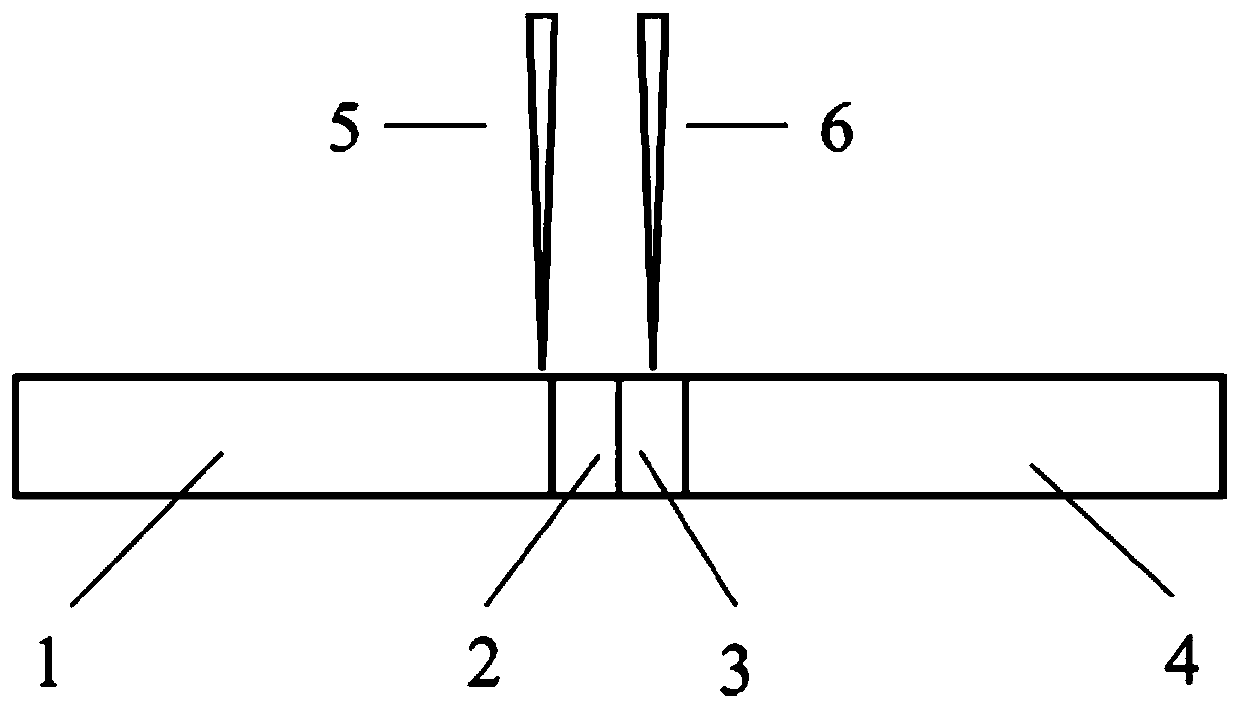

[0048] The obtained titanium alloy, kovar alloy, copper foil and niobium foil after surface cleaning are docked and placed sequentially according to kovar alloy-copper foil-niobium foil-titanium alloy. Specific as figure 1 As shown, Kovar 1, copper foil 2, niobium foil 3, and titanium alloy 4 are arranged in sequence and clamped by the clamp. Rigidly fixed in a fixture with shaped...

Embodiment 2

[0052] The welding of the titanium alloy and the Kovar alloy was carried out using the same process as in Example 1. Except that the thickness of the copper foil is 510 μm, and the thickness of the niobium foil is 380 μm, other conditions are the same as those in Example 1.

Embodiment 3

[0054] The welding of the titanium alloy and the Kovar alloy was carried out using the same process as in Example 1. Except that the thickness of the copper foil is 520 μm, and the thickness of the niobium foil is 400 μm, other conditions are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com