Benzocyclobutene functionalized double-decker type silsesquioxane and preparation method thereof and preparation method of composite resin of benzocyclobutene functionalized double-decker type silsesquioxane

A technology of benzocyclobutene-functionalized and silsesquioxane, which is applied in the field of benzocyclobutene-functionalized double-splint type silsesquioxane and its preparation, can solve the problems of reducing the dielectric constant and achieve a reduction in Dielectric constant, high thermal stability, effects of avoiding phase separation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

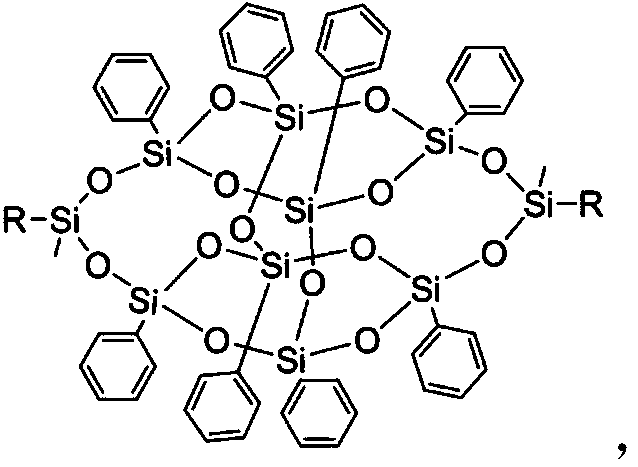

[0028] Another aspect of the present invention provides a preparation method of benzocyclobutene functionalized double splint type silsesquioxane. In an exemplary embodiment of the preparation method of the benzocyclobutene functionalized double splint type silsesquioxane of the present invention, the preparation method may include:

[0029] Step S01, preparing a dihydrooctaphenyl double splint type silsesquioxane solution.

[0030] In this example, preparing a solution of dihydrooctaphenyl bisplint silsesquioxane refers to mixing dihydrooctaphenyl bisplint silsesquioxane with a solvent to form a solution. The solvent is a conventional solvent. For example, the solvent may be toluene or tetrahydrofuran. Preferably, dihydrooctaphenyl double splint silsesquioxane (DDSQ-2H for short): solvent = 1:5-10 according to the mass-volume ratio (for example, the unit may be g / mL). Certainly, the mass volume ratio of dihydrooctaphenyl double splint type silsesquioxane to solvent is not ...

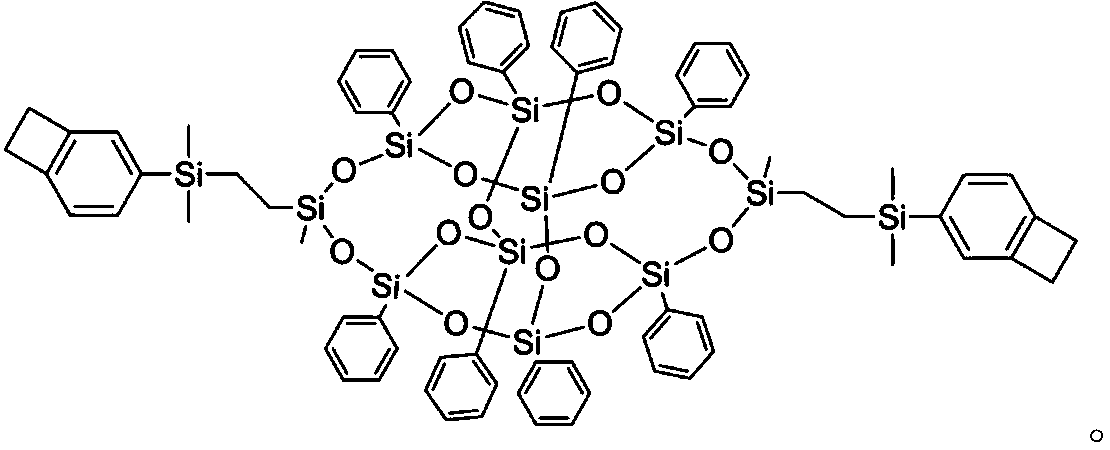

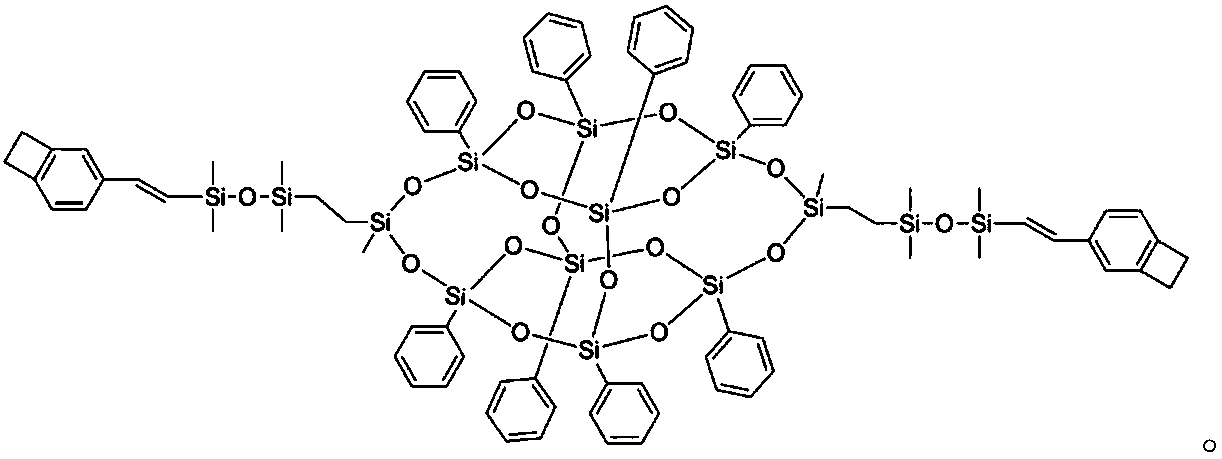

example 1

[0066] In a dry anaerobic bottle equipped with a magnetic stirrer, add 6.69 g of dihydrooctaphenyl double-splint silsesquioxane (abbreviated as DDSQ-2H), and pass through nitrogen for 10 minutes to remove the oxygen in the system, followed by Add 4.2 g of 4-(1,1-dimethyl-1-vinyl) silyl benzocyclobutene (4-DMHSBCB for short), and the molar concentration is 0.025M catalyst chloroplatinic acid (H 2 PtCl 6 ) in tetrahydrofuran (100 μL) and toluene 30 mL. Then, under a nitrogen atmosphere, the temperature was 80° C. for 72 hours, and the reaction raw material DDSQ-2H was monitored by thin-layer chromatography to see if the reaction was complete. After the reaction is finished, cool the reacted material to room temperature, filter through silica gel (remove the catalyst in the initial product) to obtain a colorless solution, and remove the colorless solution using a rotary evaporator at a pressure of -0.09MPa and a temperature of 45°C. After the toluene was evaporated (until no to...

example 2

[0070] In a dry, anaerobic bottle equipped with a magnetic stirrer, add 6.72 g of dihydrooctaphenyl double-splint silsesquioxane (DDSQ-2H for short), feed nitrogen for 15 minutes to remove the oxygen in the system, and then Add 4.4g of 4-(1,1-dimethyl-1-vinyl) silylbenzocyclobutene (abbreviated as 4-DMHSBCB), and the molar concentration is 0.025M catalyst chloroplatinic acid (H 2 PtCl 6 ) in tetrahydrofuran (THF) 100 μL and toluene 35 mL. Then, under a nitrogen atmosphere, the temperature was 65° C. for 72 hours, and the reaction raw material DDSQ-2H was monitored by thin-layer chromatography to see if the reaction was complete. After the reaction is finished, the reacted material is cooled to room temperature, filtered through silica gel (to remove the catalyst in the initial product) to obtain a colorless solution, and the colorless solution is removed using a rotary evaporator at a pressure of -0.095MPa and a temperature of 60°C. After the toluene was evaporated (until no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com