A kind of hydraulic cement clinker and its preparation method, hydraulic cement and its application

A cement clinker and hydraulic technology, which is applied in the field of hydraulic cement and its application, hydraulic cement clinker and its preparation, can solve the problems that affect the normal use of marine engineering, slow strength development, long maintenance time, etc., and achieve long-term The effect of stable strength development, high early strength and slow hydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

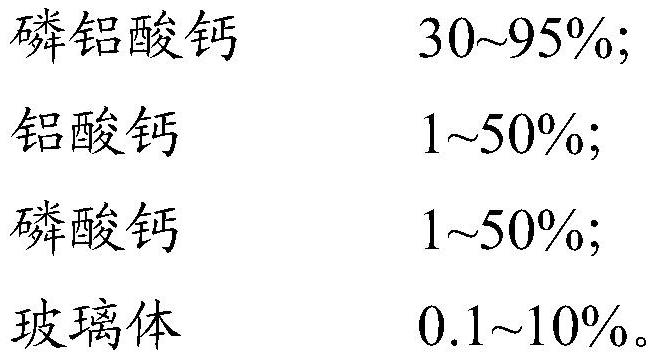

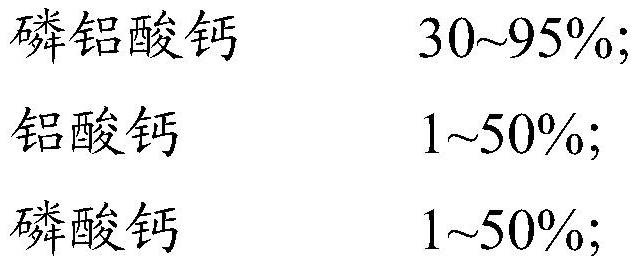

[0033] The present invention provides the preparation method of hydraulic cement clinker described in above-mentioned technical scheme, comprises the following steps:

[0034] Calcium oxide, phosphorus pentoxide and aluminum oxide are mixed to obtain a mixture; in terms of weight percentage, the mixture includes 30% to 60% of calcium oxide, 10% to 35% of phosphorus pentoxide and aluminum oxide Aluminum 30%~60%;

[0035] The mixture is calcined to obtain hydraulic cement clinker.

[0036]The present invention mixes calcium oxide, phosphorus pentoxide and aluminum oxide to obtain a mixture. In the present invention, the mixture includes 30%-60% of calcium oxide, 10%-35% of phosphorus pentoxide and 30%-60% of aluminum oxide by weight percentage. The present invention adopts the mixture with the above percentage content in order to obtain the hydraulic cement clinker with the above mineral composition. The present invention has no special requirements on the mixing method, and ...

Embodiment 1

[0050] According to the raw material ratio in Table 1, weigh calcium nitrate tetrahydrate, aluminum nitrate nonahydrate and phosphoric acid respectively, add them into deionized water to form a mixed solution, heat the mixed solution to 85°C, and keep stirring until the water evaporates to form a gel;

[0051] The gel was placed in a corundum crucible, heated to 850°C in a resistance furnace, kept for 3 hours, cooled to room temperature naturally, pulverized with a pulverizer, and passed through a 200-mesh molecular sieve to obtain calcium oxide, phosphorus pentoxide and three Precursor composed of alumina;

[0052] Use a mold to press the precursor into a cylindrical blank with a thickness of 10mm and a diameter of 40mm under a pressure of 100MPa;

[0053] Place the cylindrical billet in a resistance furnace, raise the furnace temperature from room temperature to 1537°C at a heating rate of 16°C / min, keep it warm for 2 hours, quickly take out the calcined cylindrical billet, ...

Embodiment 2~5

[0055] The hydraulic cement clinker was prepared according to the method of Example 1, and the raw materials used and the calcination temperature are shown in Table 1.

[0056] Raw material ratio and calcination temperature value in table 1 embodiment 1~5

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com