A preparation method of uniformly dispersed photocatalytic hydrogel

A technology of uniform dispersion and photocatalysis, applied in the field of hydrogel preparation, can solve the problems of low gel strength, easy particle agglomeration, and complicated process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for preparing a uniformly dispersed photocatalytic hydrogel, the preparation method comprising the steps of:

[0019] Step 1): Add 5 mL of deionized water to the Erlenmeyer flask, then add 0.05 g of sodium carboxymethylcellulose, stir and dissolve at room temperature for 20 min, then add 0.5 g of acrylamide and 1 g of acrylic acid, and stir for 5 min to obtain mixture A;

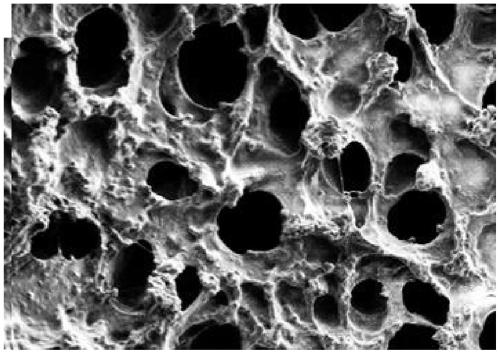

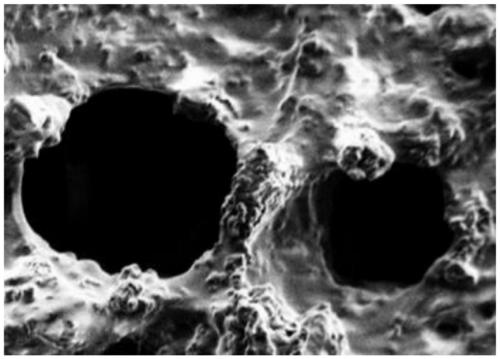

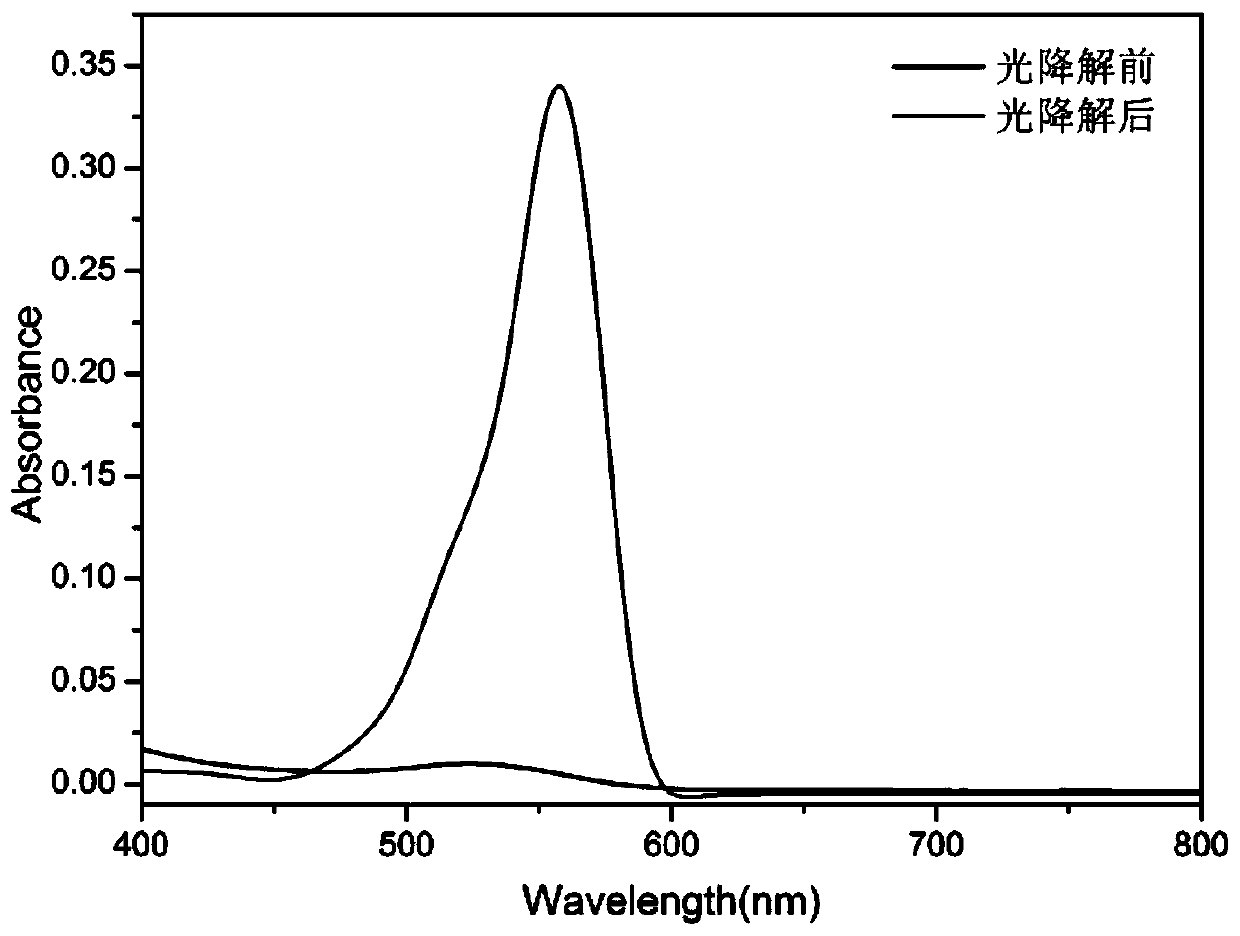

[0020] Step 2): Add 5 mg of core-shell photocatalytic nanoparticles to the mixture A obtained in step 1), ultrasonically disperse for 20 min, stir for 20 min, then add 1 mg of N, N-methylenebisacrylamide, 10 mg of potassium persulfate, 0.5 g Sodium hydroxide was stirred for 5min to obtain a mixture B. The core-shell photocatalytic nanoparticles included several titanium dioxide particles, and the titanium dioxide particles were covered with a spherical shell with several small holes. The spherical shell was Silica, wherein the nanometer fineness of the core-shell photocatalytic nanoparticles ...

Embodiment 2

[0025] A method for preparing a uniformly dispersed photocatalytic hydrogel, the preparation method comprising the steps of:

[0026] Step 1): stirring and dissolving at room temperature for 30 minutes, then adding 1 g of acrylamide and 1.5 g of acrylic acid, and stirring for 10 minutes to obtain mixture A;

[0027] Step 2): Add 10 mg of core-shell photocatalytic nanoparticles to the mixture A obtained in step 1), ultrasonically disperse for 30 min, stir for 30 min, then add 2 mg of N,N-methylenebisacrylamide, 20 mg of potassium persulfate, 1 g of hydrogen Sodium oxide was stirred for 7.5min to obtain mixture B. The core-shell photocatalytic nanoparticles included several titanium dioxide particles, and the titanium dioxide particles were covered with a spherical shell with several small holes. The spherical shell was Silica, wherein the nanometer fineness of the core-shell photocatalytic nanoparticles is 7 nanometers, the smaller the core-shell photocatalytic nanoparticle fin...

Embodiment 3

[0031] A method for preparing a uniformly dispersed photocatalytic hydrogel, the preparation method comprising the steps of:

[0032] Step 1): Add 15 mL of deionized water to the Erlenmeyer flask, then add 0.15 g of sodium carboxymethylcellulose, stir and dissolve at room temperature for 40 min, then add 1.5 g of acrylamide and 2 g of acrylic acid, and stir for 15 min to obtain mixture A;

[0033] Step 2): Add 15 mg of core-shell photocatalytic nanoparticles to the mixture A obtained in step 1), ultrasonically disperse for 40 min, stir for 40 min, then add 3 mg of N, N-methylenebisacrylamide, 30 mg of potassium persulfate, 1.5 g Sodium hydroxide was stirred for 10 min to obtain mixture B. The core-shell photocatalytic nanoparticles included several titanium dioxide particles, and the titanium dioxide particles were covered with a spherical shell with several small holes. The spherical shell was Silica, wherein the nanometer fineness of the core-shell photocatalytic nanoparticl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com