A kind of filler for fluidized bed biofilm method and its preparation method

A biofilm method and fluidized bed technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of poor hydrophilic performance and biological affinity, cumbersome molding processing steps, and short service life. and other problems, to achieve the effect of improving permeability, improving material exchange capacity, and improving the amount of film hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

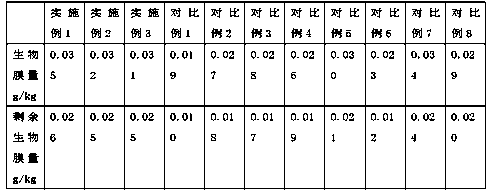

Examples

Embodiment 1

[0022] The preparation method of the filler used in the fluidized bed biofilm method is characterized in that it includes the following steps: (1) pulverizing carbonized rice husk powder, diatomaceous earth, and calcium hydroxyphosphate until the particle size is below 200 mesh, and carbonizing the rice husk 7.5 parts of powder, 7.5 parts of diatomaceous earth, 7.5 parts of calcium hydroxyphosphate, 50 parts of PVC elastomer, 30 parts of polyvinyl alcohol resin, 4 parts of hard acid, 3 parts of polyacrylamide, 15 parts of isopropyl chloride and mix well, Stir at high speed, add the above mixed material into the foam molding machine to melt and foam; (2) Then inject it into the mold to form inner layer filled microspheres with a diameter of 1.5cm; (3) Fill 60 inner layer filled microspheres The balls are added to the outer mesh bag with a mesh diameter of 0.5cm. The material of the outer mesh bag is thermoplastic resin and polypropylene, which is fixed so that it cannot slide fr...

Embodiment 2

[0024] The preparation method of the filler used in the fluidized bed biofilm method is characterized in that it includes the following steps: (1) pulverizing carbonized rice husk powder, diatomaceous earth, and calcium hydroxyphosphate until the particle size is below 200 mesh, and carbonizing the rice husk 10 parts of powder, 5 parts of diatomaceous earth, 10 parts of calcium hydroxyphosphate, 40 parts of PVC elastomer, 40 parts of polyvinyl alcohol resin, 2 parts of hard acid, 5 parts of polyacrylamide, 10 parts of isopropyl chloride, mix well, Stir at high speed, add the above-mentioned mixture into the foam molding machine to melt and foam; (2) Then inject it into the mold to form inner layer filled microspheres with a diameter of 2cm; (3) Fill 20 inner layer filled microspheres Add it into the outer mesh bag with a mesh diameter of 0.6cm. The material of the outer mesh bag is thermoplastic resin, which is polypropylene. The filler is irradiated with light, the wavelength...

Embodiment 3

[0026] The preparation method of the filler used in the fluidized bed biofilm method is characterized in that it includes the following steps: (1) pulverizing carbonized rice husk powder, diatomaceous earth, and calcium hydroxyphosphate until the particle size is below 200 mesh, and carbonizing the rice husk 5 parts of powder, 10 parts of diatomaceous earth, 5 parts of calcium hydroxyphosphate, 60 parts of PVC elastomer, 20 parts of polyvinyl alcohol resin, 6 parts of hard acid, 1 part of polyacrylamide, 20 parts of isopropyl chloride, mix well, Stir at high speed, add the above-mentioned mixture into the foam molding machine to melt and foam; (2) Then inject it into the mold to form inner layer filled microspheres with a diameter of 1cm; (3) Fill 100 inner layer filled microspheres Add it into the outer mesh bag with a mesh diameter of 0.3cm. The material of the outer mesh bag is thermoplastic resin, which is polypropylene. The filler is irradiated with light, the wavelength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com