Flame-retarding coating for wooden handicraft

A technology for flame retardant coatings and handicrafts, which is applied in the field of wooden handicraft processing and processing industry, can solve the problems of inability to reduce the damage of handicraft materials, phosphorus pollution, etc., and achieve the effects of high use efficiency, improved fire resistance and flame retardant performance, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

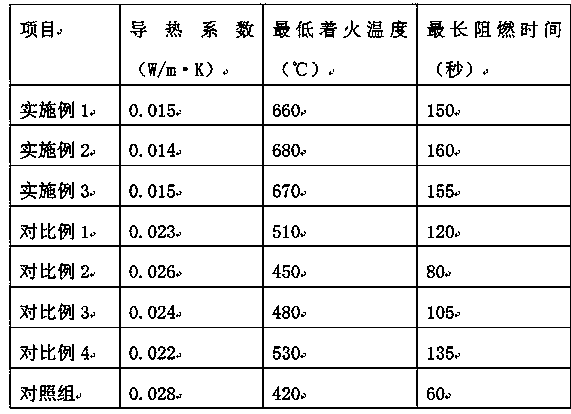

Examples

Embodiment 1

[0017] A flame-retardant coating for wooden handicrafts, which is made of the following components in parts by weight: 40 parts of polyurethane resin, 35 parts of phenolic resin, 20 parts of diatomaceous earth, 6 parts of sodium carbonate, 2.0 parts of azobisisobutyronitrile, 0.5 parts of yttrium oxide, 3.0 parts of triethanolamine, 2.0 parts of hydroxyethyl cellulose, 30 parts of paraffin, 1.0 parts of functional filler, 120 parts of urea aqueous solution; the polymer resin and diatomaceous earth are melted and mixed, and the process includes the following steps :

[0018] (1) Dry polyurethane resin, phenolic resin and diatomaceous earth separately, grind and mix according to parts by weight after drying, heat the mixed powder to 80°C, preheat for 6 hours and add them together into a twin-screw extruder for further processing Mixing, the mixing temperature is 230°C, add paraffin and urea aqueous solution to the mixing material, and continue melting;

[0019] (2) After contin...

Embodiment 2

[0026] A flame-retardant coating for wooden handicrafts, made of the following components in parts by weight: 42 parts of polyurethane resin, 36 parts of phenolic resin, 22 parts of diatomaceous earth, 7 parts of sodium carbonate, 2.5 parts of azobisisobutyronitrile, 0.6 parts of yttrium oxide, 3.5 parts of triethanolamine, 2.1 parts of hydroxyethyl cellulose, 35 parts of paraffin, 1.2 parts of functional filler, 125 parts of urea aqueous solution; the polymer resin and diatomaceous earth are melted and mixed, and the process includes the following steps :

[0027] (1) Dry polyurethane resin, phenolic resin and diatomaceous earth separately, grind and mix according to parts by weight after drying, heat the mixed powder to 85°C, preheat for 7 hours and add them together into a twin-screw extruder for Mixing, the mixing temperature is 240°C, add paraffin and urea aqueous solution to the mixing material, and continue melting;

[0028] (2) After continuing to smelt for 1.5 hours,...

Embodiment 3

[0035] A flame-retardant coating for wooden handicrafts, made of the following components in parts by weight: 45 parts of polyurethane resin, 38 parts of phenolic resin, 25 parts of diatomaceous earth, 9 parts of sodium carbonate, 3.0 parts of azobisisobutyronitrile, 0.8 parts of yttrium oxide, 4.0 parts of triethanolamine, 2.2 parts of hydroxyethyl cellulose, 40 parts of paraffin, 1.4 parts of functional filler, 130 parts of urea aqueous solution; the polymer resin and diatomaceous earth are melted and mixed, and the process includes the following steps :

[0036] (1) Dry polyurethane resin, phenolic resin and diatomaceous earth separately, grind and mix according to parts by weight after drying, heat the mixed powder to 90°C, preheat for 8 hours and add them together into a twin-screw extruder for further processing Mixing, the mixing temperature is 250°C, add paraffin and urea aqueous solution to the mixing material, and continue melting;

[0037] (2) After continuing to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com