Oxygen evolution electrocatalyst and preparation method and application thereof

An electrocatalyst and oxygen evolution technology, which is used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of high electronic conductivity, high catalytic performance, and simple and convenient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

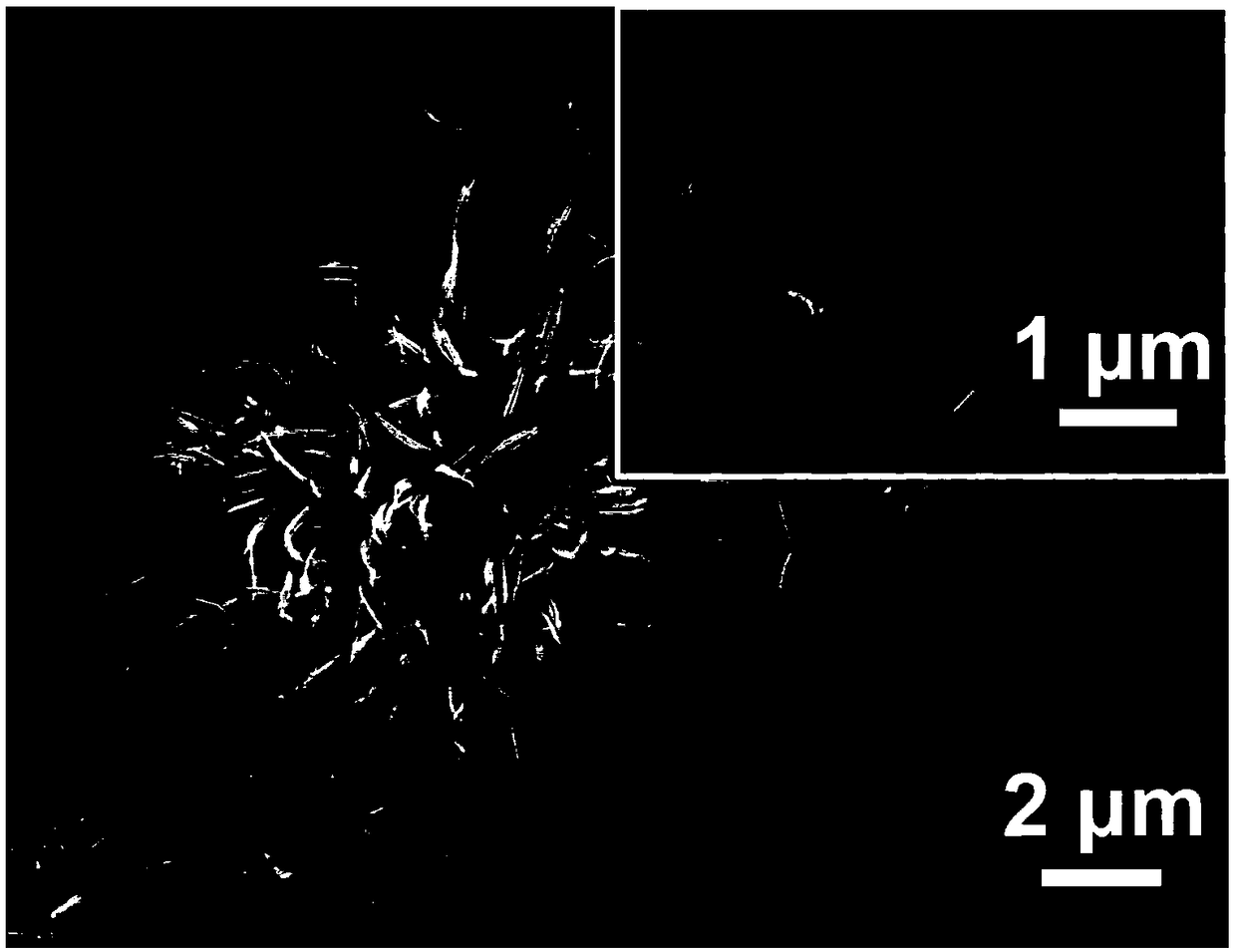

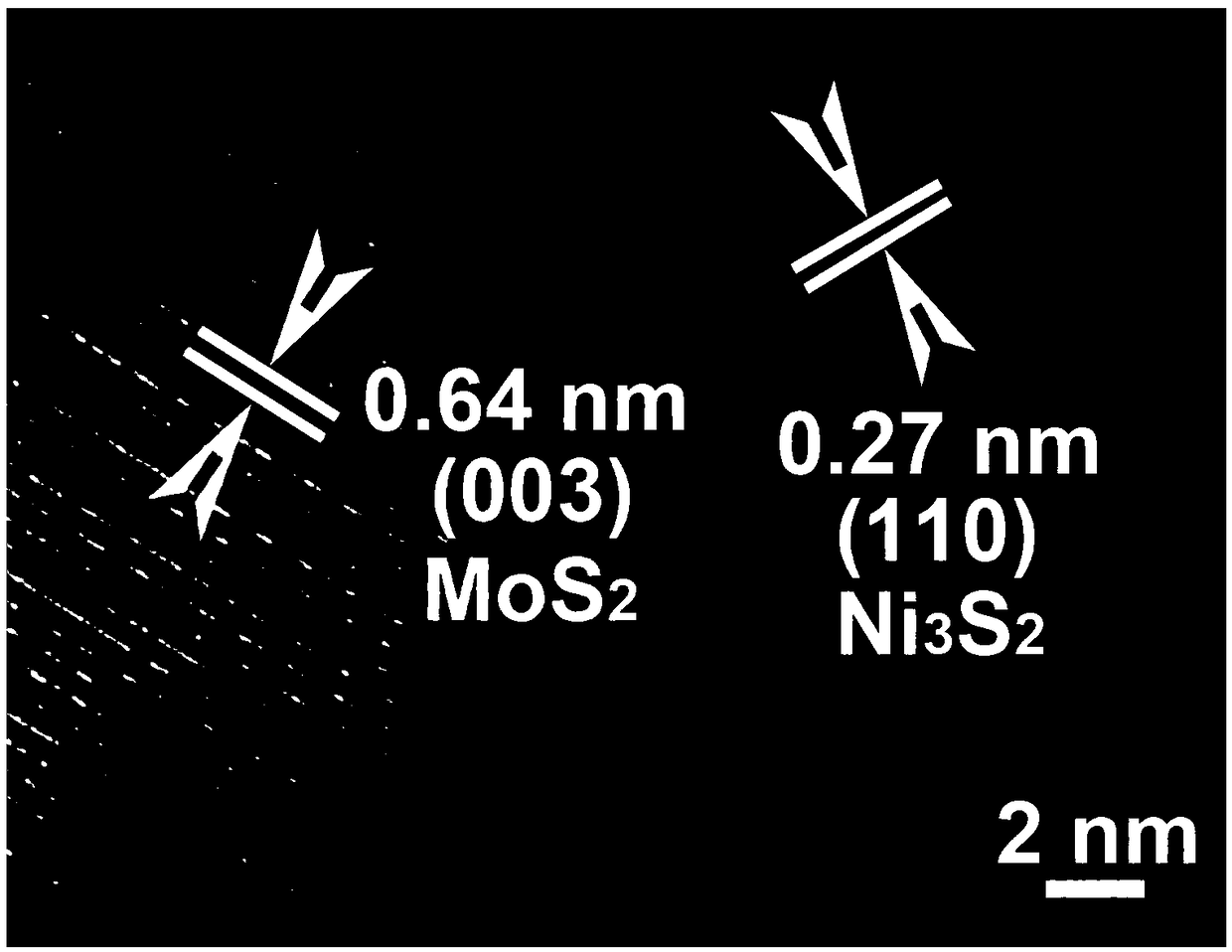

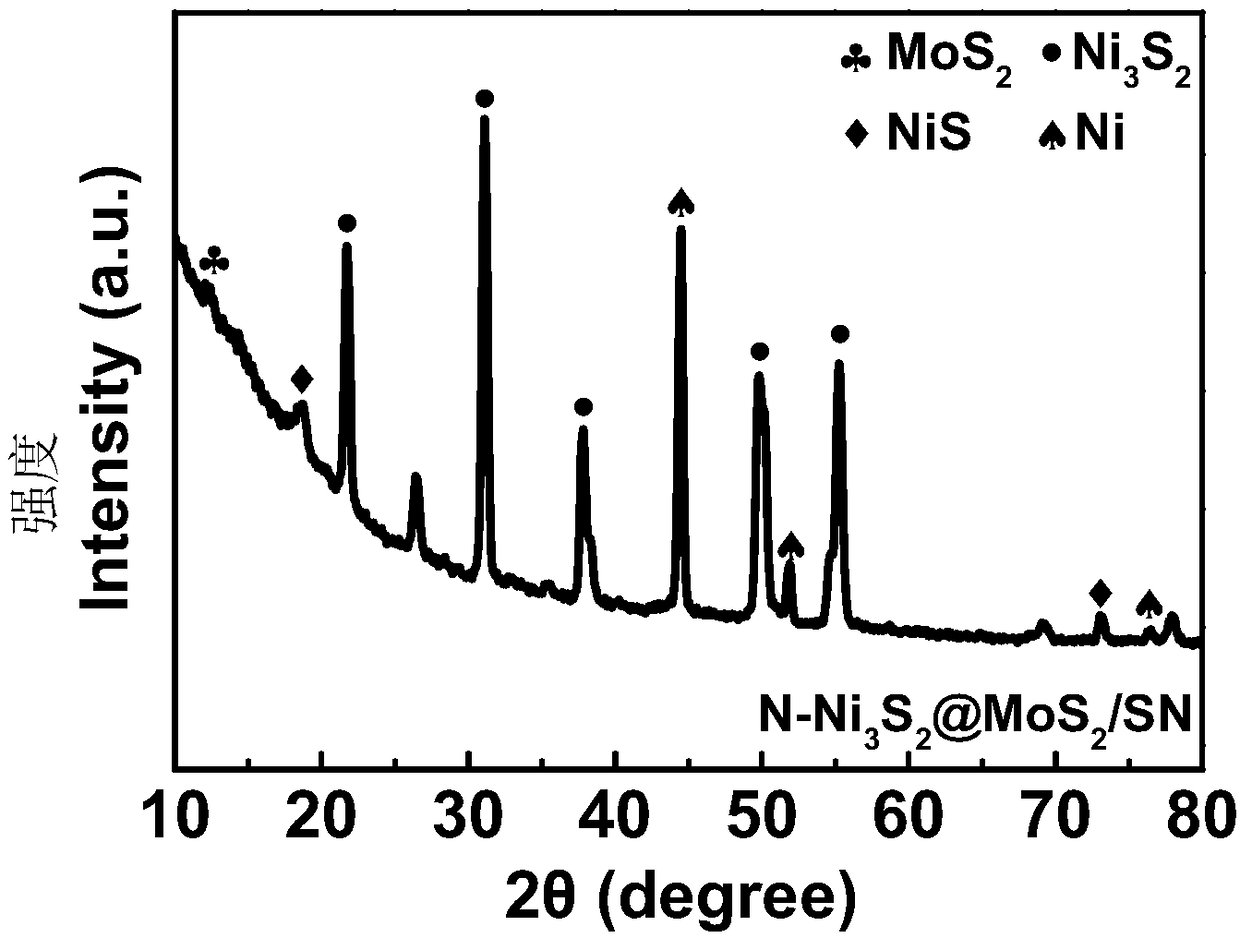

[0028] Dissolve 1.243g of nickel acetate in 69mL of deionized water, then add 6mL of hydrazine hydrate and stir evenly to form a mixed solution, add it to a polytetrafluoroethylene autoclave, put clean foamed nickel at the bottom of the kettle as a growth substrate, seal and heat, The hydrothermal temperature is 160° C., and the hydrothermal time is 6 hours. After cooling to room temperature, wash the sample with deionized water and ethanol for several times and dry it. Place the obtained sponge nickel skeleton in a mixed atmosphere of pure argon and hydrogen at a flow rate of 180sccm: 20sccm. After the temperature rises to 900°C, keep it warm After 15 minutes, ethanol gas was introduced into the reaction chamber by a bubbling method to react for 15 minutes to obtain a sponge nickel skeleton substrate covered with a layer of foamed graphene. 300mg of thiourea, 150mg of sodium molybdate and 0.4g of polyvinylpyrrolidone (PVP, K30) were dissolved in 60mL of deionized water, added...

Embodiment 2

[0031] Dissolve 1.243g of nickel acetate in 69mL of deionized water, then add 6mL of hydrazine hydrate and stir evenly to form a mixed solution, add it to a polytetrafluoroethylene autoclave, put clean foamed nickel at the bottom of the kettle as a growth substrate, seal and heat, The hydrothermal temperature is 180° C., and the hydrothermal time is 8 hours. After cooling down to room temperature, wash the sample with deionized water and ethanol for several times and dry it. Place the obtained sponge nickel skeleton in a mixed atmosphere of pure argon and hydrogen at a flow rate of 180sccm: 20sccm. After the temperature rises to 800°C, keep warm After 10 minutes, ethanol gas was introduced into the reaction chamber by a bubbling method to react for 20 minutes to obtain a sponge nickel skeleton substrate coated with a layer of foamed graphene. 300mg of thiourea, 150mg of sodium molybdate and 0.4g of polyvinylpyrrolidone (PVP, K30) were dissolved in 60mL of deionized water, adde...

Embodiment 3

[0033] Dissolve 1.243g of nickel acetate in 69mL of deionized water, then add 6mL of hydrazine hydrate and stir evenly to form a mixed solution, add it to a polytetrafluoroethylene autoclave, put clean foamed nickel at the bottom of the kettle as a growth substrate, seal and heat, The hydrothermal temperature is 200° C., and the hydrothermal time is 6 hours. After cooling to room temperature, wash the sample with deionized water and ethanol for several times and dry it. Place the obtained sponge nickel skeleton in a mixed atmosphere of pure argon and hydrogen at a flow rate of 180sccm: 20sccm. After heating up to 1000°C, keep it warm After 15 minutes, ethanol gas was introduced into the reaction chamber by a bubbling method to react for 15 minutes to obtain a sponge nickel skeleton substrate covered with a layer of foamed graphene. 300mg of thiourea, 150mg of sodium molybdate and 0.4g of polyvinylpyrrolidone (PVP, K30) were dissolved in 60mL of deionized water, added to a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com