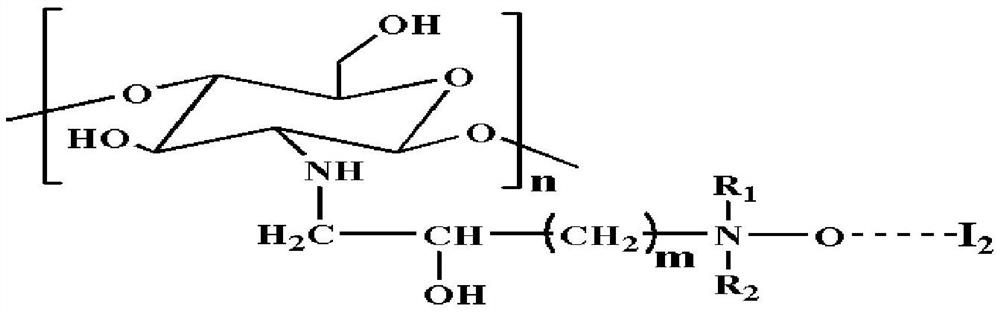

A kind of amine oxide type quaternized chitosan iodine and its preparation method and application

A technology of chitosan iodine and amine oxide, which is applied in the chemical field, can solve the problems of chitosan iodine sterilization, and the healing effect cannot reach the expected effect, and achieve the effect of degradable wound protection, wound protection and adhesion prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

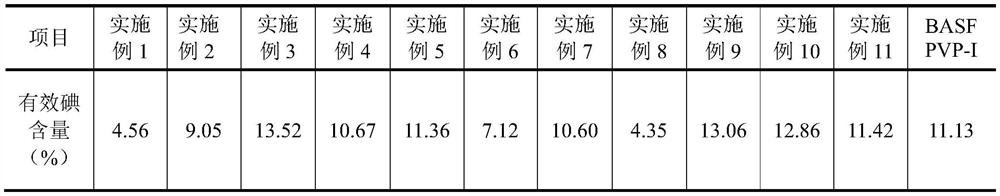

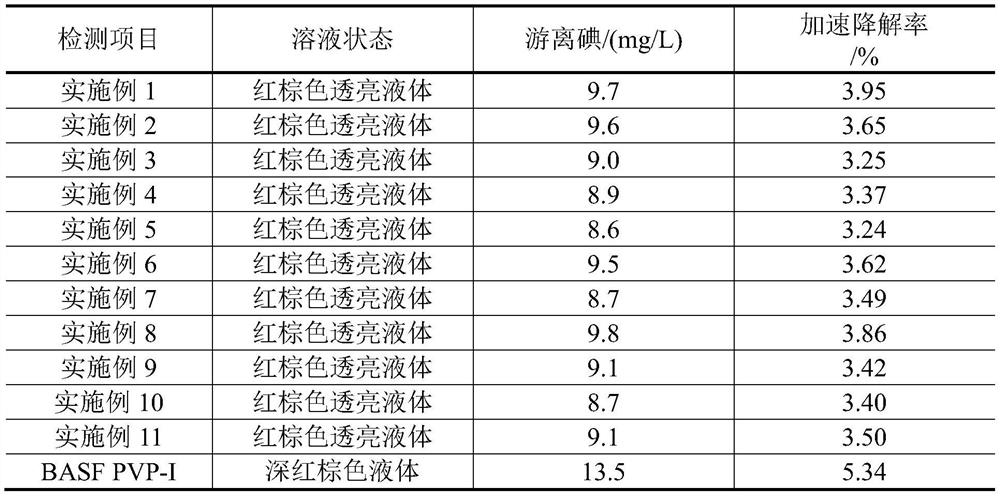

Examples

Embodiment 1

[0061] (1), preparation of quaternization reagent

[0062] Add 20g of diethyl secondary amine into 100ml of ethanol, turn on the stirring and heating device, stir evenly, control the reaction temperature at 25°C, then add 25.5g of epichlorohydrin dropwise, and control the dropping time for 30min. After the dropping is completed, The reaction was continued for 8 hours. Subsequently, the temperature was raised to 35° C., and 40.2 g of sodium hydroxide solution with a mass concentration of 30% was added dropwise, and the dropping time was controlled to be 3 hours. After the dropwise addition, the reaction was continued for 3 hours, and then the precipitated components during the reaction were filtered out, the solvent was distilled off under reduced pressure, and vacuum-dried at 40° C. to obtain the quaternization reagent.

[0063] (2), prepare quaternized chitosan

[0064] Dissolve 5g of chitosan in 100g of acetic acid solution with a mass concentration of 1%, turn on the stir...

Embodiment 2

[0069] (1), preparation of quaternization reagent

[0070] Add 20g of dipentyl secondary amine to 50ml of ethanol, turn on the stirring and heating device, stir evenly, control the reaction temperature at 30°C, then add 25.5g of epoxychlorobutane dropwise, and control the dropping time to 40min. , continue to react for 7 hours. Subsequently, the temperature was raised to 35° C., and 40.2 g of a sodium hydroxide solution with a mass concentration of 30% was added dropwise, and the dropping time was controlled to be 2 hours. After the dropwise addition was completed, the reaction was continued for 4 hours, and then the precipitated components during the reaction were filtered out, the solvent was distilled off under reduced pressure, and vacuum-dried at 40° C. to obtain the quaternization reagent.

[0071] (2), prepare quaternized chitosan

[0072] Dissolve 10g of chitosan in 100g of citric acid solution with a mass concentration of 2%, turn on the stirring and heating device,...

Embodiment 3

[0077] (1), preparation of quaternization reagent

[0078] Add 20g of diethanol secondary amine into 33.3ml of isopropanol, turn on the stirring and heating device, stir evenly, control the reaction temperature to 35°C, then add 25.5g of epichloropentane dropwise, control the dropping time to 60min, add dropwise After completion, the reaction was continued for 6 hours. Subsequently, the temperature was raised to 40° C., and 40.2 g of sodium hydroxide solution with a mass concentration of 30% was added dropwise, and the dropping time was controlled to be 4 hours. After the dropwise addition was completed, the reaction was continued for 5 hours, and then the precipitated components during the reaction were filtered out, the solvent was distilled off under reduced pressure, and vacuum-dried at 50° C. to obtain a quaternization reagent.

[0079] (2), prepare quaternized chitosan

[0080] Dissolve 15g of chitosan in 100g of oxalic acid solution with a mass concentration of 3%, tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com