Copper-graphene composite coating on surface of integrated circuit ceramic circuit board and preparation method thereof

A ceramic circuit board and graphene composite technology, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve problems such as electroplating copper pollution, achieve good adhesion, reduce substrate temperature, and diffusion capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

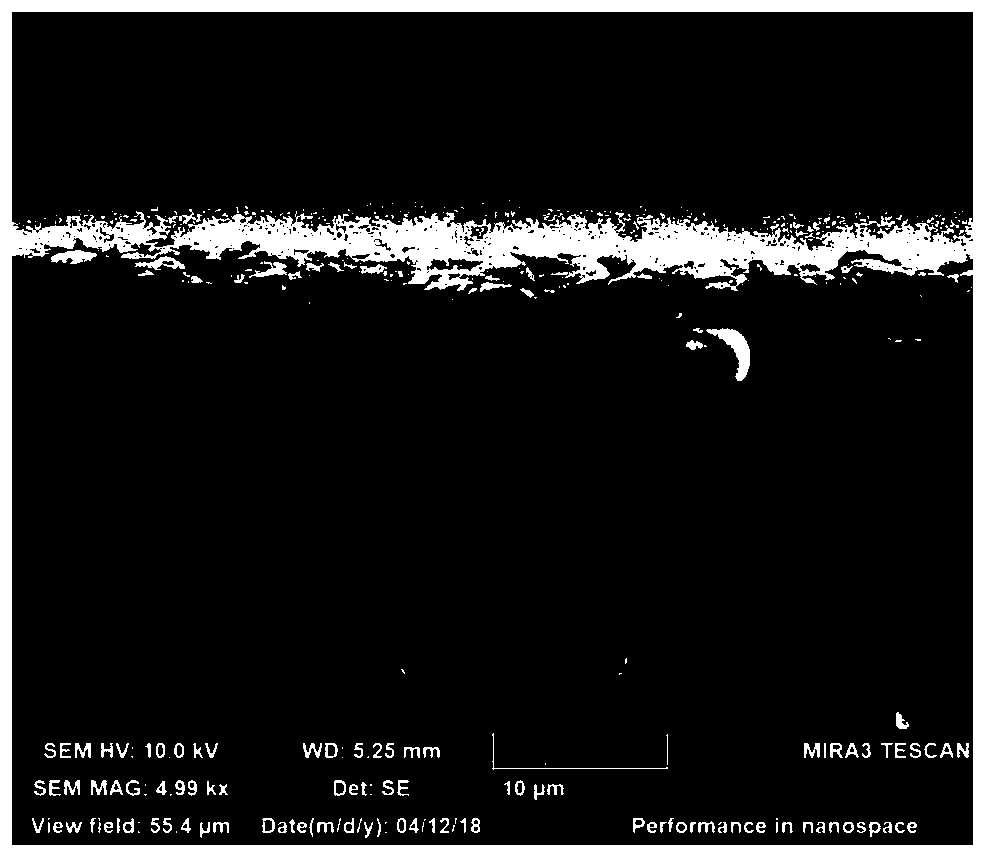

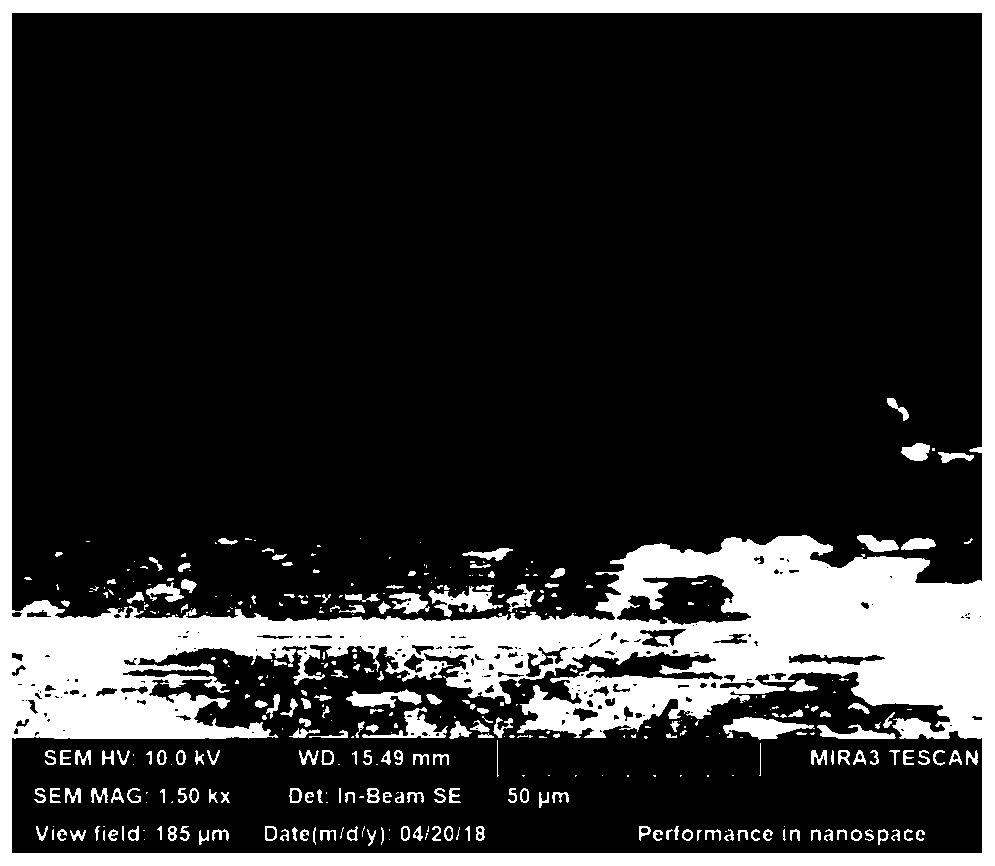

Image

Examples

Embodiment 1

[0037] (1) In a vacuum environment, the surface of the ceramic circuit board is first cleaned with an arc ion source, and then the ceramic circuit board is ion-bombarded with high-pulse arc ion plating technology. The bombardment bias is 500V, and the high temperature of the plasma is used to form a metal diffusion layer. Layer depth 1 nm;

[0038] (2) On the basis of the diffusion layer, reduce the coating bias to prepare the metal bonding layer, and the deposition bias is 50V. The thickness of the bonding layer is 5 nanometers, and the grain size is 20 nanometers;

[0039] (3) After the preparation of the bonding layer is completed, open the intermediate frequency magnetron copper target, prepare Ti / Cu alternating multi-layer transition layer, Ti / Cu alternate multi-layer transition layer, the modulation cycle thickness is 10 nanometers, and the thickness of the single-layer Ti layer is 5 nanometers, the single-layer Cu thickness is 5 nanometers; the main purpose of the alte...

Embodiment 2

[0043] (1) In a vacuum environment, the surface of the ceramic circuit board is first cleaned with an arc ion source, and then the ceramic circuit board is ion-bombarded with a high-pulse arc ion plating technology. The bombardment bias is 1000V, and the high temperature of the plasma is used to form a metal diffusion layer. Layer depth 5 nm;

[0044] (2) On the basis of the diffusion layer, reduce the coating bias to prepare the metal bonding layer, and the deposition bias is 200V. The thickness of the bonding layer is 300 nanometers, and the grain size is 3 nanometers;

[0045] (3) After the preparation of the bonding layer is completed, open the intermediate frequency magnetron copper target, prepare Cr / Cu alternating multi-layer transition layer, Cr / Cu alternate multi-layer transition layer, the modulation cycle thickness is 100 nanometers, and the single-layer Cr layer thickness is 50 nanometers, the single-layer Cu thickness is 50 nanometers; the main purpose of the alt...

Embodiment 3

[0049] (1) In a vacuum environment, the surface of the ceramic circuit board is first cleaned with an arc ion source, and then the ceramic circuit board is bombarded with ions using high-pulse arc ion plating technology. Layer depth 5 nm;

[0050] (2) On the basis of the diffusion layer, reduce the coating bias to prepare the metal bonding layer, and the deposition bias is 150V. The thickness of the bonding layer is 200 nanometers, and the grain size is 20 nanometers;

[0051] (3) After the preparation of the bonding layer is completed, open the intermediate frequency magnetron copper target, prepare Zr / Cu alternating multi-layer transition layer, Zr / Cu alternate multi-layer transition layer, the modulation cycle thickness is 80 nanometers, and the thickness of the single-layer Zr layer is 40 nanometers, the single-layer Cu thickness is 40 nanometers; the main purpose of the alternating transition layer is to improve the bonding force between the Zr layer and the Cu layer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com