Preparation method of silicon carbide foam ceramics by thermocurable polycarbosilane

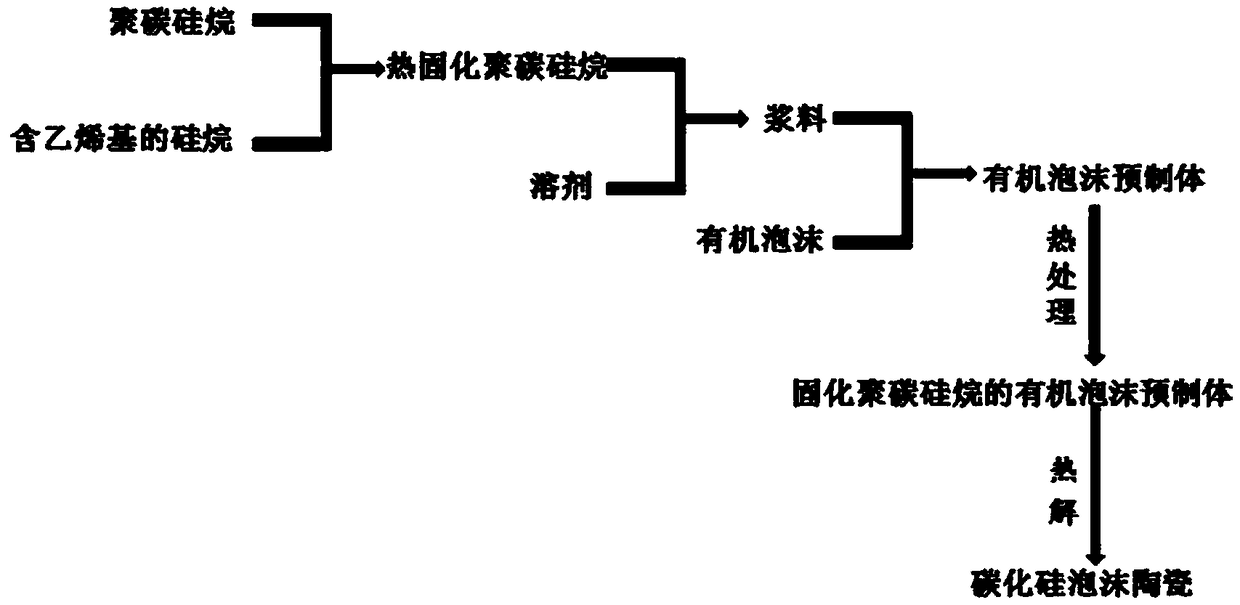

A polycarbosilane and foam ceramic technology, applied in the field of ceramic foam, can solve the problems of high oxygen content, collapsed foam pores, and difficulty in ensuring oxidation uniformity, and achieves the effects of simple preparation process, excellent performance and sufficient raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation method of preparing silicon carbide foamed ceramics with thermally curable polycarbosilane is as follows:

[0046] (1) Preparation of PVCS

[0047] The polycarbosilane synthesized by cracking and rearranging polydimethylsilane has a softening point of 230°C and a number average molecular weight of 1750.

[0048] Add the PCS and tetravinylcyclotetrasiloxane to the reaction kettle at a mass ratio of 1:0.3, add xylene at a ratio of 10ml / g to xylene / PCS, and then use chloroplatinic acid / PCS as the Add chloroplatinic acid at a ratio of 100ppm as a catalyst, vacuumize and replace high-purity argon, then heat to 120°C, keep the temperature for 20 hours, then stop the reaction, cool to room temperature, place the product solution in a distillation device, Under protection, the temperature was raised to 80° C., and the solvent and unreacted silane compound were distilled off under reduced pressure to obtain the product PVCS.

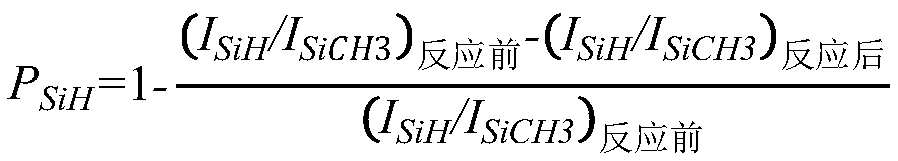

[0049] Using the calculation metho...

Embodiment 2

[0058] The preparation method of preparing silicon carbide foamed ceramics with thermally curable polycarbosilane is as follows:

[0059] The polycarbosilane synthesized by cracking and rearranging polydimethylsilane has a softening point of 220°C and a number average molecular weight of 1700.

[0060] Add the PCS and tri(isoallyloxy)vinylsilane to the reaction kettle at a mass ratio of 1:0.5, add xylene at a ratio of 15ml / g to xylene / PCS, and then mix with chloroplatinic acid Add chloroplatinic acid at a ratio of 100ppm / PCS as a catalyst, vacuumize, replace high-purity argon three times, then heat to 120°C, keep warm for 22 hours, stop the reaction, cool to room temperature, and place the product solution in a distillation device , under the protection of high-purity argon, the temperature was raised to 90 ° C, and the solvent and unreacted silane compound were distilled off under reduced pressure to obtain the product PVCS.

[0061] Using the calculation method for the degr...

Embodiment 3

[0070] The preparation method of preparing silicon carbide foamed ceramics with thermally curable polycarbosilane is as follows:

[0071] The preparation of step (one) PVCS is the same as embodiment 1

[0072] (2) Impregnation to obtain organic foam preform

[0073] The PVCS obtained above is mixed with xylene to form a solution with a viscosity of 40 Pa·s; the organic foam is used as a template, and an organic foam preform is obtained after impregnation.

[0074] Step (three) and (four) are the same as embodiment 2

[0075] Obtain black bright silicon carbide foam ceramics. Bulk density 0.5g / cm 3 , The open porosity is between 85%, and the flexural strength is up to 2.3MPa.

[0076] Using an EMGA-620W model oxygen and nitrogen analyzer, the oxygen content of the silicon carbide foam ceramics prepared above was measured to be 7.5 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com