A kind of technology for preparing epoxy fatty acid isooctyl ester based on biodiesel

An epoxy fatty acid, biodiesel technology, applied in sustainable manufacturing/processing, chemical industry, organic chemistry, etc., can solve problems such as unreported treatment methods, large equipment investment, and many process steps, and achieve easy recycling and reuse. , the effect of reducing production energy consumption, process efficiency and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

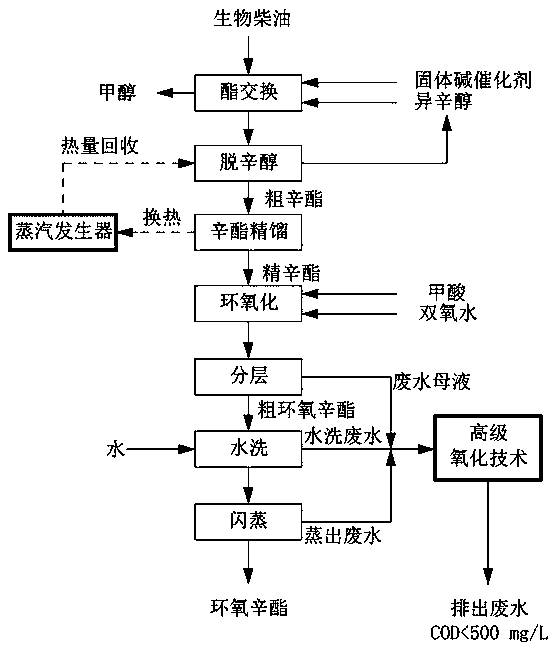

[0020] Such as figure 1 Shown, biodiesel and isooctyl alcohol take place transesterification reaction under the condition of solid alkali potassium carbonate as catalyst, reaction condition is: alcohol oil molar ratio is 3:1, and catalyst consumption is 3wt.% of oil weight, and reaction temperature is At 180 ℃, the reaction time is 1 h, and fatty acid isooctyl esters are obtained. Under these conditions, the conversion rate of biodiesel can reach 100%. And the catalyst can be directly reused, and the conversion rate is higher than 99% after repeated use for 5 times.

Embodiment 2

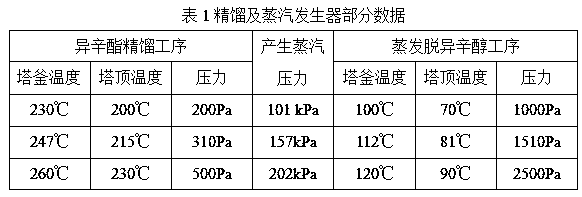

[0022] Fatty acid isooctyl esters have a high boiling point, and high-temperature and high-vacuum rectification is required to purify the product. Such as figure 1 As shown, during the rectification of isooctyl ester, the temperature of the tower bottom is controlled to be 230° C., the temperature of the tower top is 200° C., and the pressure is 200 Pa. The distillation condition of iso-octanol is to control the temperature of the tower bottom at 100°C, the temperature at the top of the tower at 70°C, and the pressure at 1000Pa. Change the operating conditions, as shown in Table 1:

[0023]

[0024] It can be seen that the fatty acid isooctyl ester steamed from the top of the tower is used to recover heat through the steam generator, and the steam pressure (gauge pressure) is 101-202kPa. The heat recovered in this step is used for distillation to remove and recover isooctyl after the transesterification reaction. Heat source of alcohol. The generated steam is heated enou...

Embodiment 3

[0026] Such as figure 1 As shown, fatty acid isooctyl ester, hydrogen peroxide and formic acid undergo epoxidation reaction, reaction conditions: fatty acid isooctyl ester double bond content / hydrogen peroxide / formic acid is 1 / 1.5 / 0.25 (molar ratio), reaction temperature is 65°C, reaction time For 10 hours, after the epoxidation reaction, the reactants were layered. The upper oil phase was crude epoxy fatty acid isooctyl ester, and the lower water phase was the mother liquor containing formic acid wastewater. The thick epoxy fatty acid isooctyl ester was washed to medium through hot water. and then undergo flash evaporation to obtain refined epoxy fatty acid isooctyl ester; after the formic acid-containing wastewater mother liquor, washing wastewater, and flash-evaporated wastewater are combined, hydrogen peroxide in the wastewater system is used for advanced oxidation treatment. The concentration of hydrogen peroxide in the system is about 5% of the wastewater. %, the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com