Nitrogen and phosphorus doped porous carbon-rhodium phosphide catalyst as well as preparation method and application thereof

A technology of rhodium catalyst and porous carbon, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex synthesis steps, inability to synthesize on a large scale, and difficulty in large-scale synthesis, etc. Achieve the effect of simple synthesis method, easy promotion and industrialization, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the porous carbon-rhodium phosphide catalyst doped with nitrogen and phosphorus in the present embodiment is as follows:

[0033] 1) Add 1 volume of glucose and 2 weights of diglyphosate to 20 volumes of water, stir and mix evenly, and prepare a mixed solvent;

[0034] 2) Add 2 volumes of rhodium chloride to the mixed solvent, stir magnetically for 1 hour, prepare a uniform mixed solution, heat to 150° C., keep for 2 hours, turn the mixed solution into a sol and colloid, and cool it down;

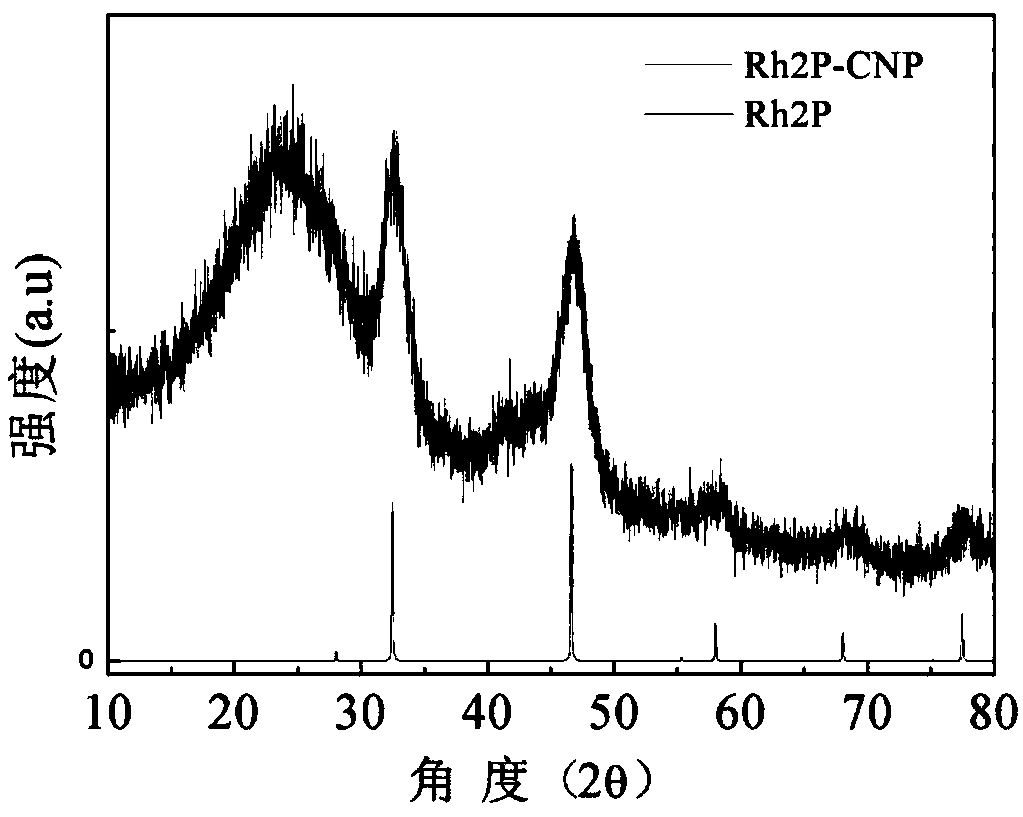

[0035] 3) Put the obtained sol colloid into an oven at 60°C and keep it for 48 hours to dry until it becomes a yellow powder. Grind the yellow powder with a grinder and pass through a 400-mesh molecular sieve, collect the ground product, and then put it in a 600°C oven Furnace calcining 8h, obtains the porous carbon-rhodium phosphide nano material of black nitrogen phosphorus doping;

[0036] 4) After cleaning the black nanomaterial with water and ethanol f...

Embodiment 2

[0040] This embodiment is the same as embodiment 1, the difference is that in this embodiment,

[0041] The raw materials used in step (1) are 20 volumes of water, 2 weights of flour, 0.5 volumes of melamine and 2 volumes of phytic acid;

[0042] Step (2) Add 2 volumes of rhodium nitrate, heat to 120°C, and keep for 15h;

[0043] Step (3) The drying temperature is 80°C for 48 hours, and the calcination temperature is 1100°C for 8 hours;

[0044] The drying temperature in step (4) is 110°C.

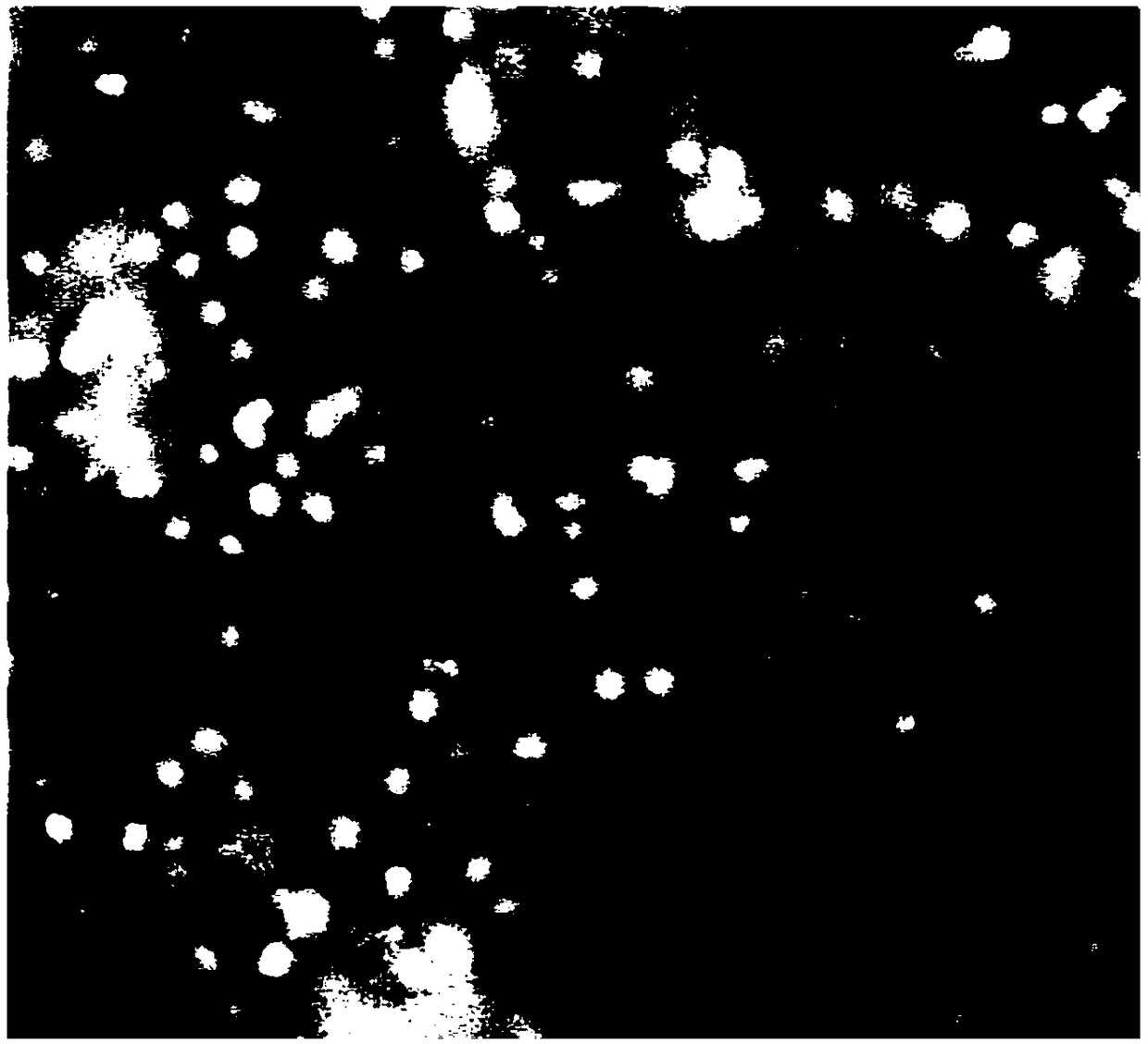

[0045] The prepared nitrogen-phosphorus-doped porous carbon-rhodium phosphide nanomaterial catalyst has a special composite structure, with nitrogen-phosphorus-doped porous carbon loaded with 5-12nm-sized particles, and rhodium phosphide nanoparticles are wrapped in the middle of porous carbon .

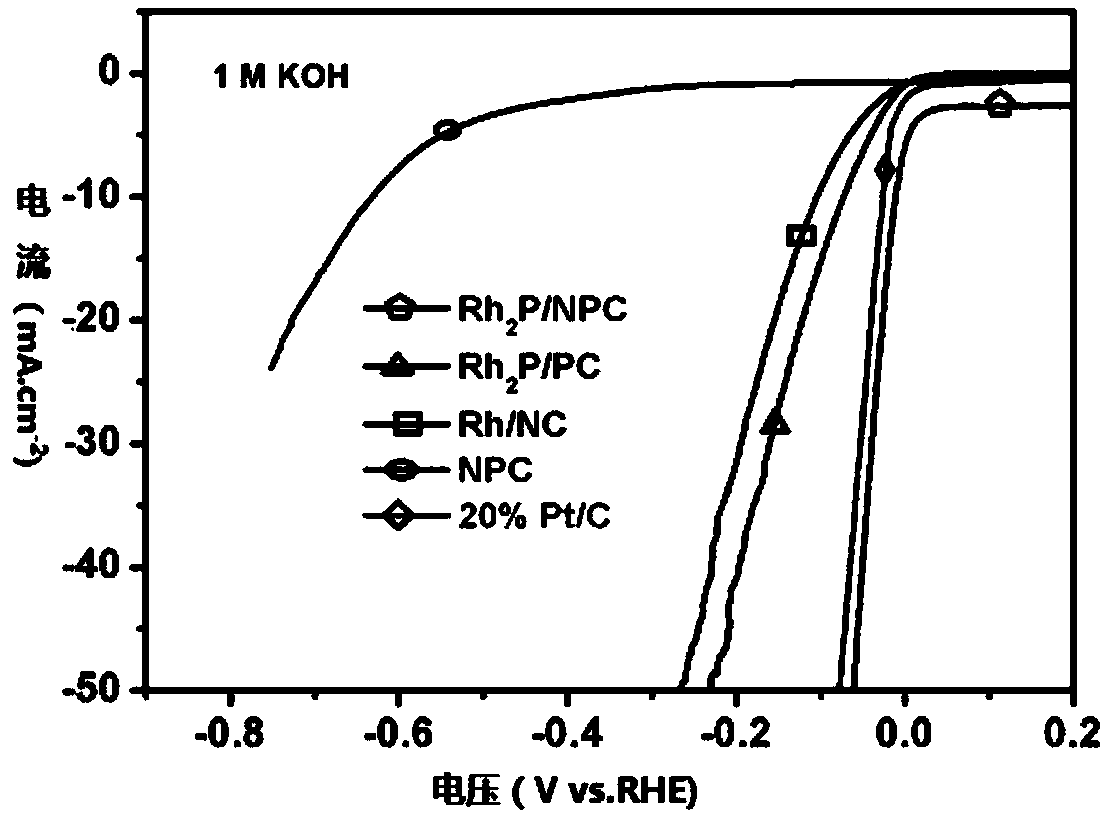

[0046] The nitrogen and phosphorus doped porous carbon-rhodium phosphide nanomaterial catalyst obtained in Example 2 was used as the electrolyzed water hydrogen production catalyst, and the si...

Embodiment 3

[0048] This embodiment is the same as embodiment 1, the difference is that in this embodiment,

[0049] The raw materials used in step (1) are 40 volumes of water, 5 weights of starch, 2 weights of urea and 3 volumes of phytic acid;

[0050] Step (2) Add 3 volumes of rhodium nitrate, heat to 90°C, and keep for 20h;

[0051] Step (3) The drying temperature is 100°C for 48 hours, and the calcination temperature is 1000°C for 8 hours;

[0052] The drying temperature in step (4) is 110°C.

[0053] The prepared nitrogen-phosphorus-doped porous carbon-rhodium phosphide nanomaterial catalyst has a special composite structure, with nitrogen-phosphorus-doped porous carbon loaded with 10-30nm-sized particles, and rhodium phosphide nanoparticles are wrapped in the middle of porous carbon .

[0054] The nitrogen and phosphorus doped porous carbon-rhodium phosphide nanomaterial catalyst obtained in Example 3 was used as the electrolyzed water hydrogen production catalyst, and the simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com