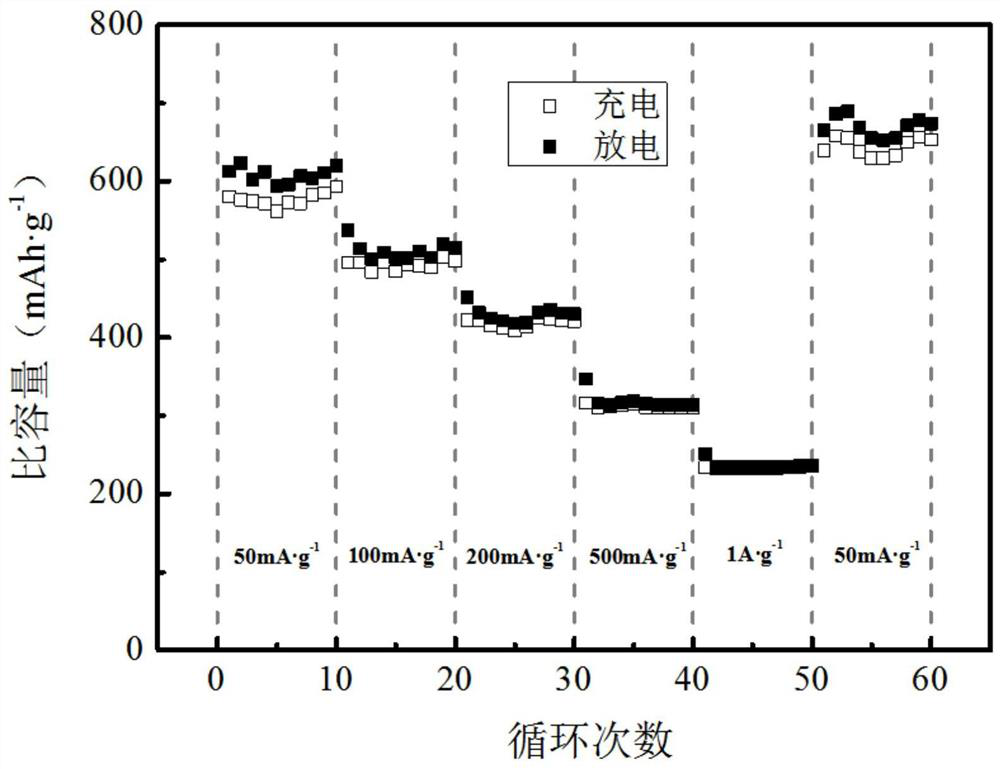

A kind of lignin porous carbon with uniform pores and its preparation method and application in lithium ion battery negative electrode material

A technology of lignin and porous carbon, which is used in battery electrodes, carbon preparation/purification, circuits, etc., can solve the problems affecting lithium ion transmission and extraction/insertion, uneven pore size distribution, and uneven pore structure. The effect of uniform size, saving resources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

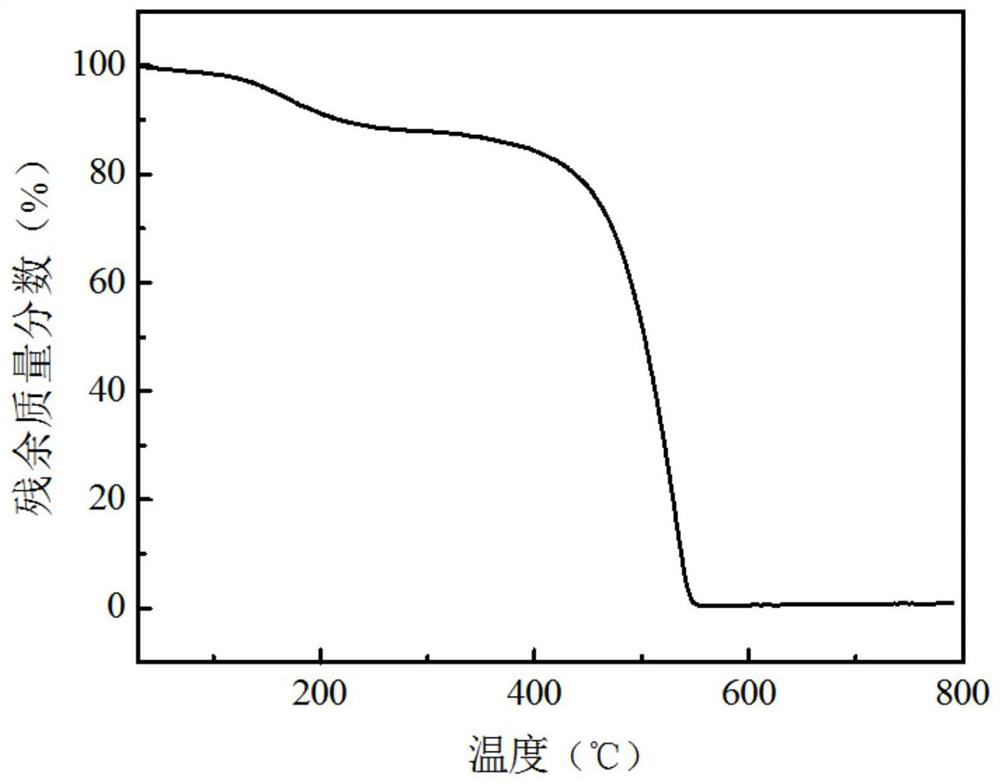

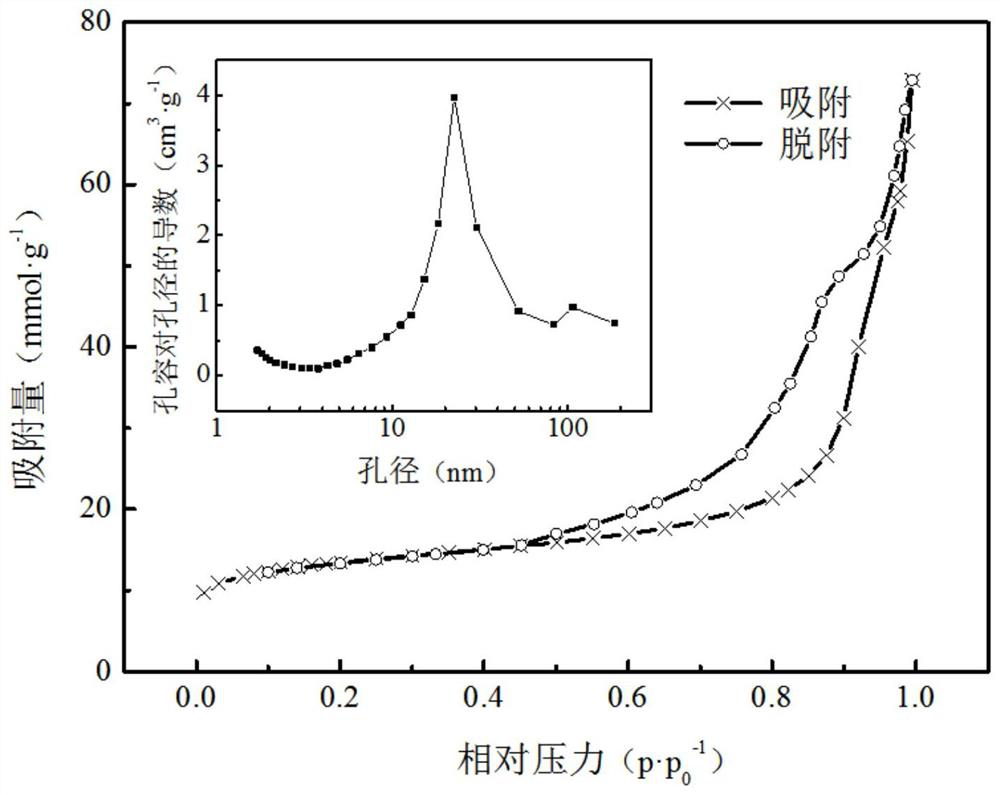

[0051] Mix 1g of wood pulp alkali lignin solid powder and 0.1g of sodium benzoate and dissolve in 200mL of absolute ethanol, add 1g of nano-silica (particle size 20nm) and mix evenly, stir at a rate of 5mL / min 200 mL of water was added, the precipitate was separated by centrifugation, and dried to obtain a silica / lignin mixture.

[0052] Take 1g of the silica / lignin mixture and place it in a hydrothermal reaction kettle, add 100mL of water with pH=2, mix well, heat to 120°C, react for 1h, filter and separate to obtain a precipitate, dry it and place it in a nitrogen atmosphere to raise the temperature Keep at 600°C for 2 hours to obtain a silica / lignin-carbon composite material, and finally place it in a 1mol / L NaOH solution and stir for 24 hours, then wash with water, filter, and dry to obtain a lignin porous carbon material .

Embodiment 2

[0054] Mix 1g of wheatgrass lignin solid powder and 0.1g of sodium p-aminobenzoate and dissolve in 50mL of absolute ethanol, add 0.1g of nano-silica (particle size 100nm) and mix evenly, stir at 30mL / min 500 mL of water was added at a rate of 1000 mph, the precipitate was separated by centrifugation, and the silica / lignin mixture was obtained after drying.

[0055] Take 1g of the silica / lignin mixture and place it in a hydrothermal reaction kettle, add 10mL of water with pH=4, mix well, heat to 120°C, react for 3h, filter and separate to obtain a precipitate, dry it and place it in a nitrogen atmosphere to raise the temperature Keep at 900°C for 2 hours to obtain a silica / lignin carbon composite material, and finally place it in a 2mol / L NaOH solution and stir for 12 hours, then wash with water, filter and dry to obtain a lignin porous carbon material .

Embodiment 3

[0057] Mix 0.5g wheatgrass alkali lignin and 0.5g bamboo pulp alkali lignin solid powder with 0.1g sodium p-aminobenzenesulfonate and dissolve in 50mL absolute ethanol, add 0.25g nano silicon dioxide (30nm particle size) and Mix evenly, add 150 mL of water at a rate of 30 mL / min under stirring, centrifuge to separate the precipitate, and dry to obtain a silica / lignin mixture.

[0058] Take 1g of the silica / lignin mixture and place it in a hydrothermal reaction kettle, add 20mL of water with pH=3, mix well, heat to 200°C, react for 1h, filter and separate to obtain a precipitate, dry it and place it in a nitrogen atmosphere to raise the temperature Keep at 600°C for 5 hours to obtain a silica / lignin-carbon composite material, and finally place it in a 3mol / L KOH solution and stir for 10 hours, then wash with water, filter, and dry to obtain a lignin porous carbon material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com