High strength cable protective pipe, and preparation method thereof

A cable protection tube, high-strength technology, applied in the field of high-strength cable protection tube and its preparation, can solve the problems of easy aging of PVC materials, poor anti-aging performance of materials, complicated preparation and installation, etc., and achieves enhanced wear resistance and mechanical mechanics. Excellent performance, flexural and compressive resistance and mechanical impact resistance, and the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

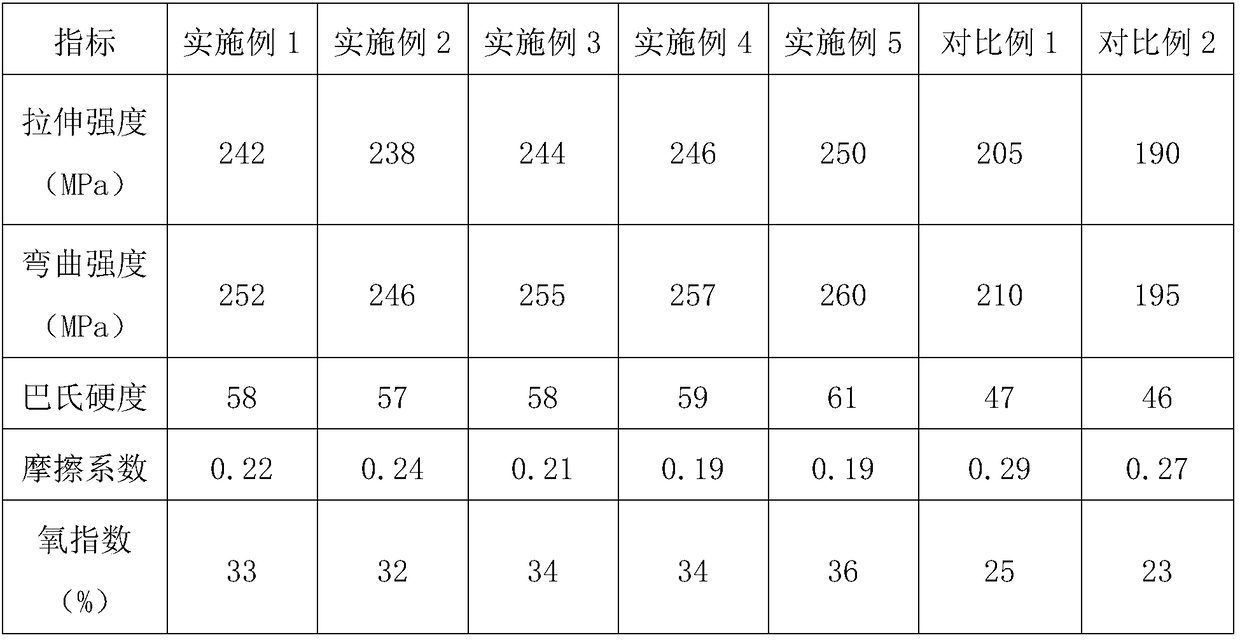

Examples

Embodiment 1

[0032] A high-strength cable protection tube, comprising the following raw materials in parts by weight:

[0033] 80 parts of polypropylene, 15 parts of low density polyethylene, 3 parts of maleic anhydride grafted polypropylene, 5 parts of castor oil, 15 parts of nano light calcium carbonate, 6 parts of nano mica, 3 parts of nano zinc oxide, hollow glass microspheres 5 parts, 6 parts of modified nano-boron fiber, 3 parts of modified nano-titanium dioxide, 1.2 parts of crosslinking agent, 1.6 parts of antioxidant and 2.4 parts of flame retardant.

[0034] The preparation method of the modified nano-boron fiber is as follows:

[0035] (1) After adding nano-boron fiber into 50% sulfuric acid solution and soaking it for 5 hours, rinse it with deionization;

[0036] (2) Add the nano-boron fibers treated in step (1) into 0.25 mol / liter chromic acid solution, heat up to 45-50 degrees Celsius, stir and mix for 8 minutes at a speed of 400 rpm, filter, and deionized water Clean the f...

Embodiment 2

[0049] A high-strength cable protection tube, comprising the following raw materials in parts by weight:

[0050] 90 parts of polypropylene, 20 parts of low density polyethylene, 7 parts of maleic anhydride grafted polypropylene, 10 parts of castor oil, 20 parts of nano light calcium carbonate, 12 parts of nano mica, 7 parts of nano zinc oxide, hollow glass microspheres 10 parts, 12 parts of modified nano-boron fiber, 7 parts of modified nano-titanium dioxide, 2.6 parts of crosslinking agent, 3.2 parts of antioxidant and 3.8 parts of flame retardant.

[0051] The preparation method of the modified nano-boron fiber is as follows:

[0052] (1) After adding the nano-boron fiber into 60% sulfuric acid solution and soaking it for 8 hours, rinse it with deionization;

[0053] (2) Add the nano-boron fibers treated in step (1) into 0.25 mol / liter chromic acid solution, heat up to 50 degrees Celsius, stir and mix at a speed of 600 rpm for 15 minutes, filter, and wash the filtrate with...

Embodiment 3

[0066] A high-strength cable protection tube, comprising the following raw materials in parts by weight:

[0067] 83 parts of polypropylene, 16 parts of low density polyethylene, 4 parts of maleic anhydride grafted polypropylene, 6 parts of castor oil, 16 parts of nano light calcium carbonate, 7 parts of nano mica, 4 parts of nano zinc oxide, hollow glass microspheres 6 parts, 7 parts of modified nano boron fiber, 4 parts of modified nano titanium dioxide, 1.6 parts of crosslinking agent, 2.1 parts of antioxidant and 2.8 parts of flame retardant.

[0068] The preparation method of the modified nano-boron fiber is as follows:

[0069] (1) After adding the nano-boron fiber into 55% sulfuric acid solution and soaking it for 7 hours, rinse it with deionization;

[0070] (2) Add the nano-boron fibers treated in step (1) into 0.25 mol / liter chromic acid solution, heat up to 48 degrees Celsius, stir and mix for 10 minutes at a speed of 450 rpm, filter, and wash the filtrate with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com