Antibacterial cleaner for refrigerators and preparation method thereof

A technology for cleaning agents and refrigerators, applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of easy moisture absorption and saturation, unpleasant odors in refrigerators, slow adsorption speed, etc., and achieve antibacterial effects. Significant, enhanced sterilization effect, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the antibacterial cleaning agent for refrigerators of the present invention, according to the proportioning by weight, is realized by the following steps:

[0035] Step 1: At room temperature, add nonionic surfactant to deionized water, stir, and mix well to obtain solution A;

[0036] Step 2: In solution A, add environment-friendly solvent one by one, stir until mixed evenly, and obtain solution B;

[0037] Step 3: Add an anti-oil redeposition agent into solution B, stir until it dissolves evenly, and obtain solution C;

[0038] Step 4: In solution C, add a safe antibacterial agent, continue to stir until the mixture is uniform, and obtain solution D;

[0039] Step 5: Add conventional additives to solution D, stir until dissolved evenly, and finally obtain transparent liquid E, which is made into an antibacterial cleaner for refrigerators.

Embodiment 1

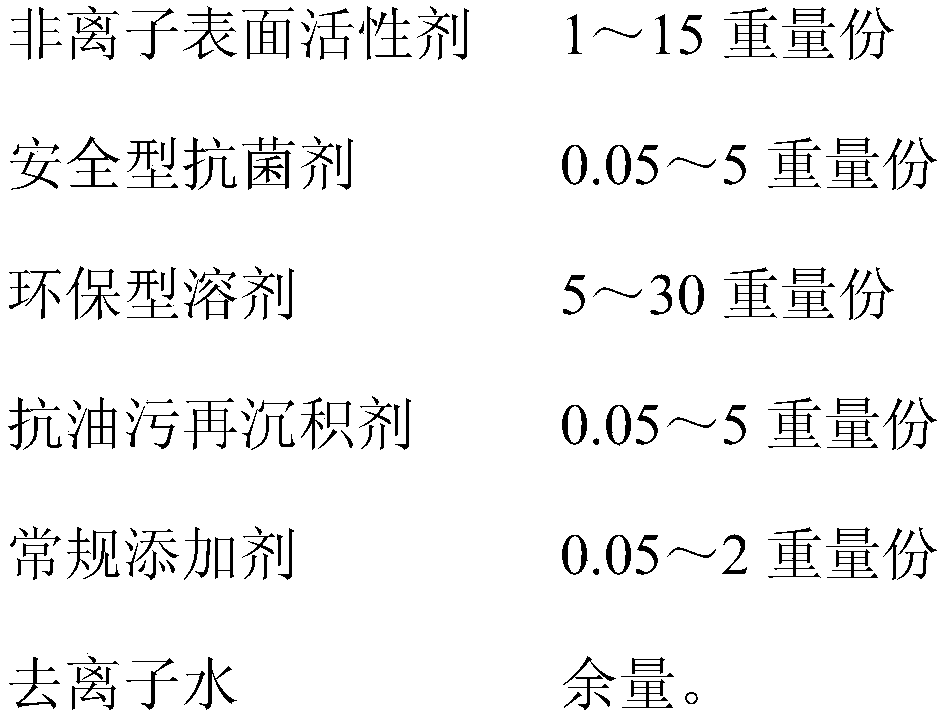

[0041] An antibacterial cleaning agent for a refrigerator according to the present invention has the following components in parts by weight: 1 part by weight of a nonionic surfactant; 0.05 parts by weight of a safe antibacterial agent; 5 parts by weight of an environment-friendly solvent; and 0.05 parts by weight of an anti-greasy redeposition agent ; 0.05 parts by weight of conventional additives; the balance is deionized water.

[0042] The nonionic surfactant is one or a mixture of polyglycerol fatty acid esters, coconut oil fatty acid alkanolamides, fatty alcohol polyoxyethylene ethers, sucrose esters, and alkyl glycosides.

[0043] The safe antibacterial agent is chlorhexidine gluconate, ε-polylysine, (polylysine, organic acid, amino acid) mixture, natural organic antibacterial agent A.SAP, polyhexamethylene hydrochloride di One or a mixture of guanidines.

[0044] The environment-friendly solvent is in compliance with EU 1999 / 13 / EC regulations on the management of vola...

Embodiment 2

[0055] The components of an antibacterial cleaning agent for a refrigerator of the present invention are as follows in parts by weight: 8 parts by weight of nonionic surfactant; 3 parts by weight of safe antibacterial agent; 15 parts by weight of environment-friendly solvent; 2.5 parts by weight of anti-oil redeposition agent ; 1 part by weight of conventional additives; the balance is deionized water.

[0056] The nonionic surfactant is one or a mixture of polyglycerol fatty acid esters, coconut oil fatty acid alkanolamides, fatty alcohol polyoxyethylene ethers, sucrose esters, and alkyl glycosides.

[0057] The safe antibacterial agent is chlorhexidine gluconate, ε-polylysine, (polylysine, organic acid, amino acid) mixture, natural organic antibacterial agent A.SAP, polyhexamethylene hydrochloride di One or a mixture of guanidines.

[0058] The environment-friendly solvent is in compliance with EU 1999 / 13 / EC regulations on the management of volatile organic solvents, EU 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com