Heat-resistant aluminum alloy die-casting demolding agent and preparation method and application method thereof

A technology of aluminum alloy and mold release agent, which is used in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of high temperature resistance, high temperature resistance and stability, etc. Good effect of placement stability, promotion of solidification sequence, cooling and thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

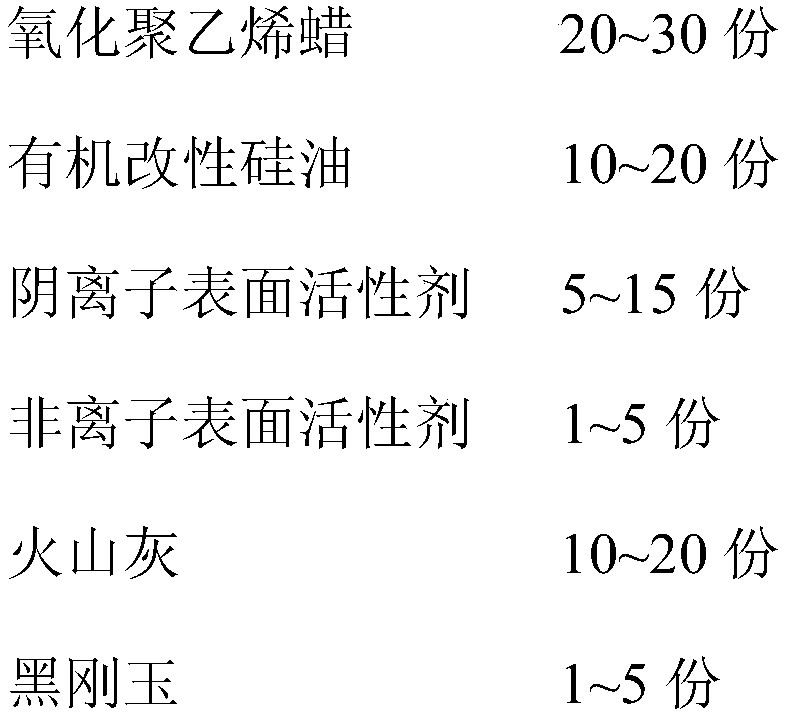

[0048] A heat-resistant aluminum alloy die-casting mold release agent of the present embodiment comprises the following components in parts by weight:

[0049]

[0050] Among them, the fineness of the volcanic ash is 300 mesh.

[0051] The preparation method of a heat-resistant aluminum alloy die-casting release agent in this embodiment, according to the above ratio, add oxidized polyethylene wax and organically modified silicone oil into the reaction kettle and mix them for 2 hours until uniform, then add volcanic ash and black corundum After mixing, stir evenly. After heating up to 80°C, add anionic surfactant, nonionic surfactant, triethanolamine and water and continue stirring for 3 hours until the viscosity is 5000Pa·s. Stop stirring to obtain the heat-resistant aluminum alloy die-casting demoulding agent.

[0052] The above-mentioned heat-resistant aluminum alloy die-casting mold release agent that is made is used for the die-casting of automobile aluminum alloy whee...

Embodiment 2

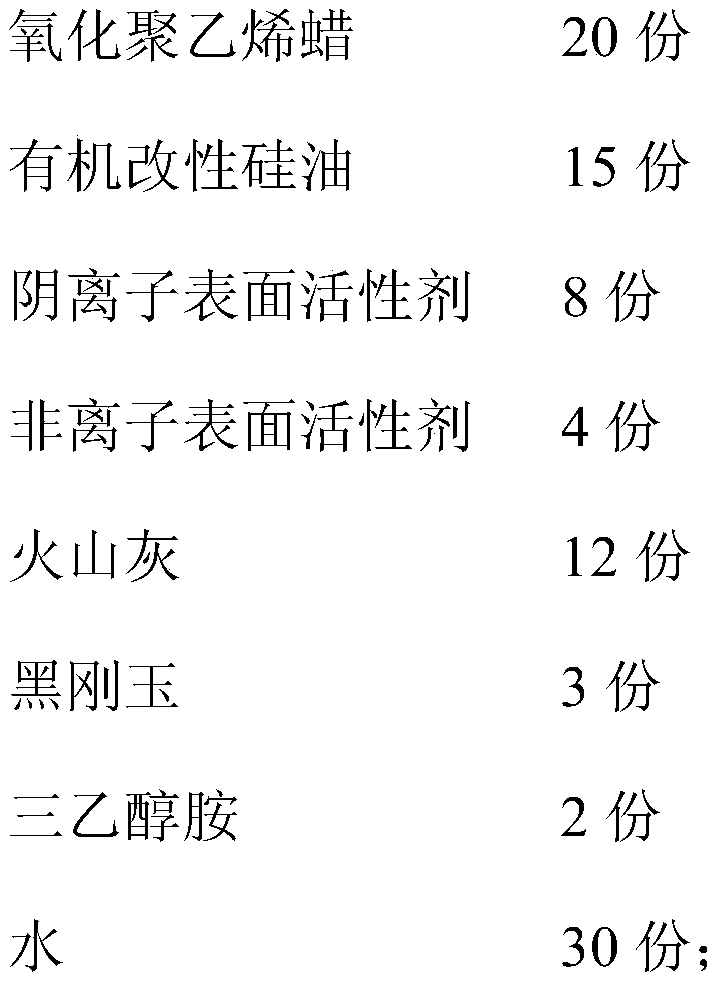

[0056] A heat-resistant aluminum alloy die-casting mold release agent of the present embodiment comprises the following components in parts by weight:

[0057]

[0058] Among them, the fineness of the volcanic ash is 400 mesh.

[0059] The preparation method of a heat-resistant aluminum alloy die-casting release agent in this embodiment, according to the above ratio, add oxidized polyethylene wax and organically modified silicone oil into the reaction kettle and mix them for 3 hours until uniform, then add volcanic ash and black corundum After mixing, stir evenly. After heating up to 60°C, add anionic surfactant, nonionic surfactant, triethanolamine and water and continue stirring for 4 hours until the viscosity is 3000Pa·s. Stop stirring to obtain the heat-resistant aluminum alloy die-casting demoulding agent.

[0060] The above-mentioned heat-resistant aluminum alloy die-casting mold release agent that is made is used for the die-casting of automobile aluminum alloy whee...

Embodiment 3

[0064] A heat-resistant aluminum alloy die-casting mold release agent of the present embodiment comprises the following components in parts by weight:

[0065]

[0066] Among them, the fineness of the volcanic ash is 500 mesh.

[0067] The preparation method of a heat-resistant aluminum alloy die-casting release agent in this embodiment, according to the above ratio, add oxidized polyethylene wax and organically modified silicone oil into the reaction kettle and mix them for 1 hour until uniform, then add volcanic ash and black corundum After mixing, stir evenly. After heating up to 70°C, add anionic surfactant, nonionic surfactant, triethanolamine and water and continue stirring for 3 hours until the viscosity is 6000Pa·s. Stop stirring to obtain the heat-resistant aluminum alloy die-casting demoulding agent.

[0068] The above-mentioned heat-resistant aluminum alloy die-casting mold release agent that is made is used for the die-casting of automobile aluminum alloy wheel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com