Preparation method of nano ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of product separation and collection difficulties, low synthesis efficiency, environmental pollution, etc., and achieve high synthesis efficiency , easy operation, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The feature of the nano ZSM-5 molecular sieve prepared by the present invention is characterized by the following methods:

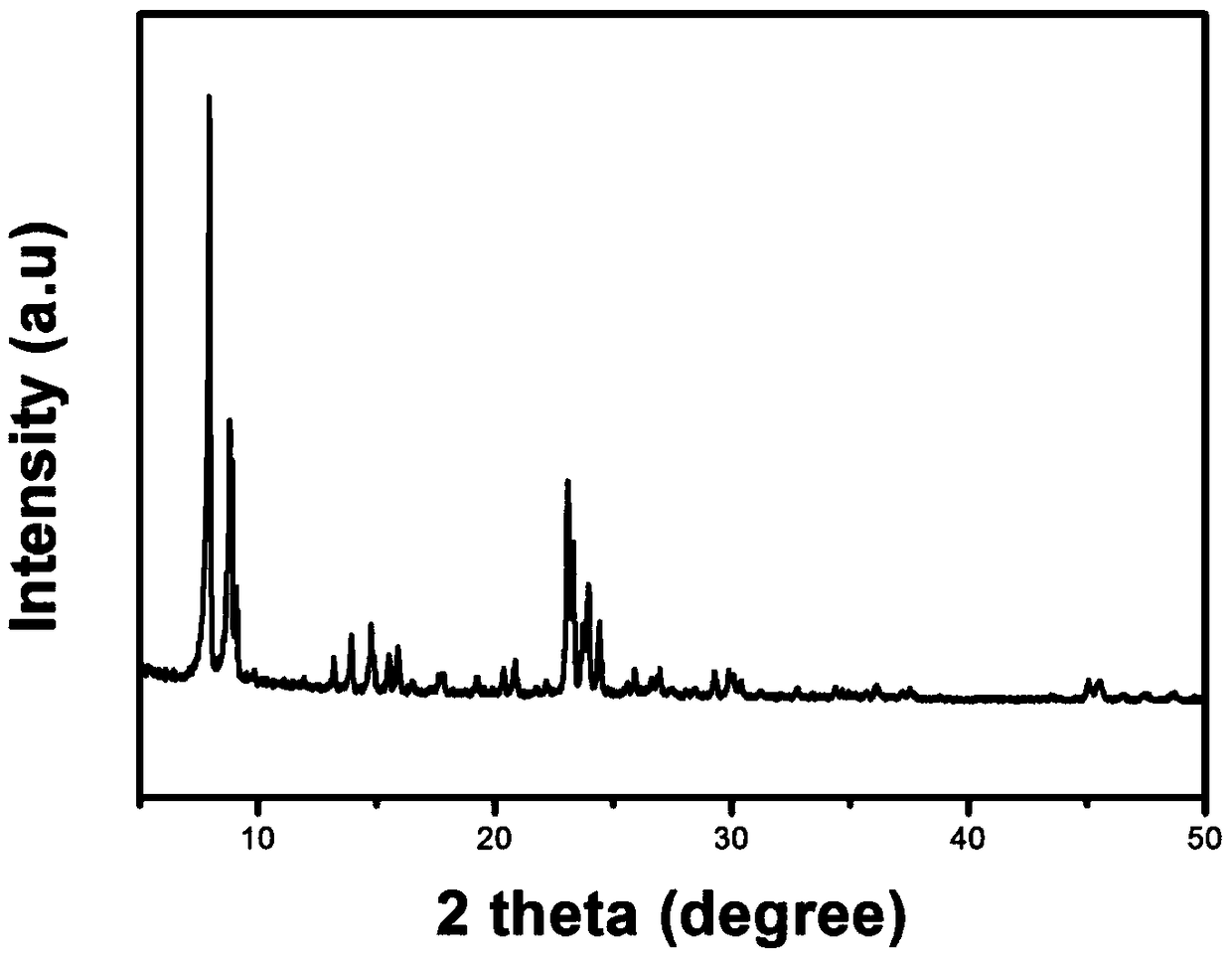

[0035] The phase structure and crystallinity of molecular sieves were characterized by powder X-ray diffraction (XRD).

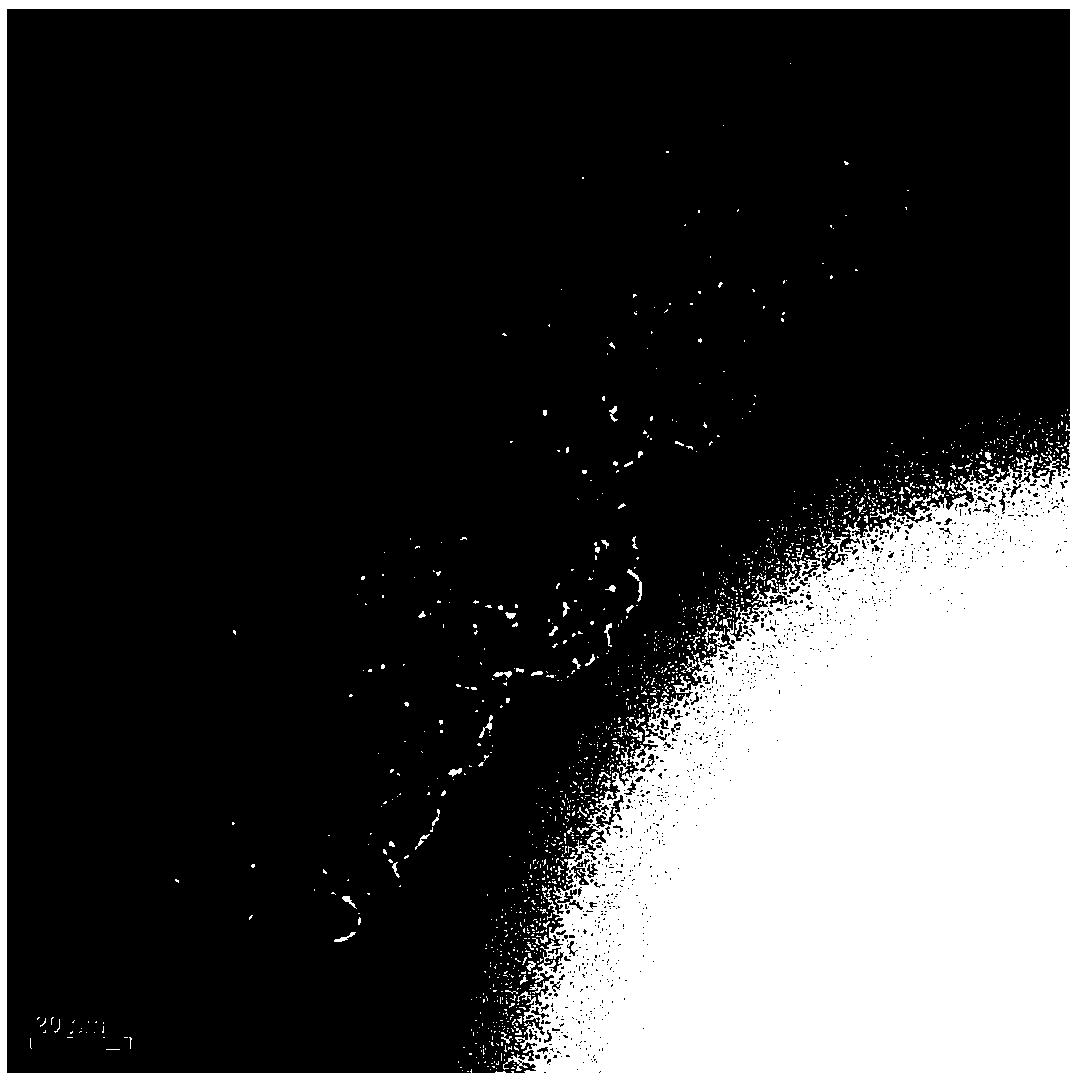

[0036] The crystal morphology and size of molecular sieves can be observed intuitively by scanning electron microscope (SEM) and transmission electron microscope (TEM).

[0037] The nitrogen adsorption experiment was used to measure the surface area, isotherm adsorption curve and pore size distribution of the molecular sieve, and judge its pore structure.

[0038]A kind of preparation method of nanometer ZSM-5 molecular sieve, the high molecular polymer polyvinylpyrrolidone of 3.2g is dissolved in the deionized water of 40.0g, room temperature is stirred to fully dissolving, forms mixed solution A; Adds the aluminum source of 0.2g and 10.4g of silicon source, continue to stir at constant temperature until it is uniformly mixed ...

Embodiment 2

[0041] A preparation method of nanometer ZSM-5 molecular sieves, comprising: dissolving 1.6g of high molecular polymer polyvinylpyrrolidone in 40.0g of deionized water, stirring at room temperature until completely dissolved to form mixed solution A; adding 0.2g of aluminum source in turn and 10.4g of silicon source, continue to stir at constant temperature until they are uniformly mixed to form solution B; then add 3.0g of structure directing agent dropwise to solution B to form a mixed solution, and stir and age the above mixed solution in a constant temperature water bath at 60°C for 24 hours to form a sol-gel Glue; Dry the above-mentioned sol-gel to obtain dry glue, transfer the ground dry glue to a crystallization kettle, use steam-assisted crystallization to realize the molecular sieve crystallization process, crystallize at 180°C for 36h, and the obtained product is filtered, Dry to obtain the molecular sieve powder. Put the original molecular sieve powder in a muffle f...

Embodiment 3

[0043] A kind of preparation method of nanometer ZSM-5 molecular sieve: the polymer polyvinylpyrrolidone of 6.4g is dissolved in the deionized water of 40.0g, stirs at room temperature until completely dissolving, forms mixed solution A; Adds the aluminum source of 0.2g and 10.4g of silicon source, continue to stir at constant temperature until it is uniformly mixed to form solution B; then add 3.0g of structure directing agent dropwise to solution B to form a mixed solution, and stir and age the above mixed solution in a constant temperature water bath at 60°C for 24 hours to form a sol-gel Dry the above-mentioned sol-gel to obtain dry glue, transfer the ground dry glue to a crystallization kettle, use steam-assisted crystallization method to realize the molecular sieve crystallization process, crystallize at 180°C for 36h, and the obtained product is filtered and dried Dry to obtain molecular sieve powder. Put the original molecular sieve powder in a muffle furnace and roast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com