Chemical nickel-tin-tungsten-phosphorus-plating amorphous multifunctional alloy plating solution and plating thereof

An electroless nickel plating, amorphous technology, applied in the field of electroless plating, can solve problems such as failure of anti-corrosion and wear resistance of the coating, decrease in hardness and wear resistance, rough coating, etc., to suppress the precipitation of hydrogen ions, increase hardness, and improve fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

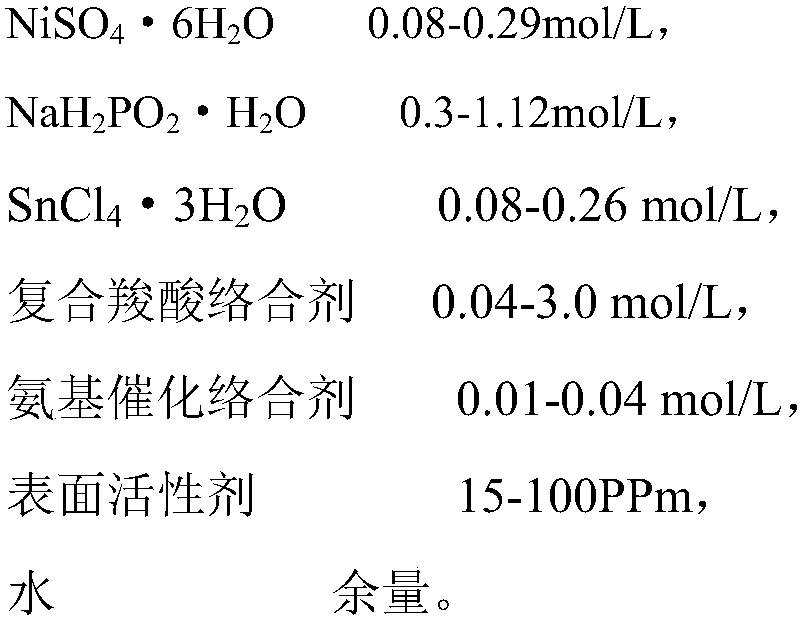

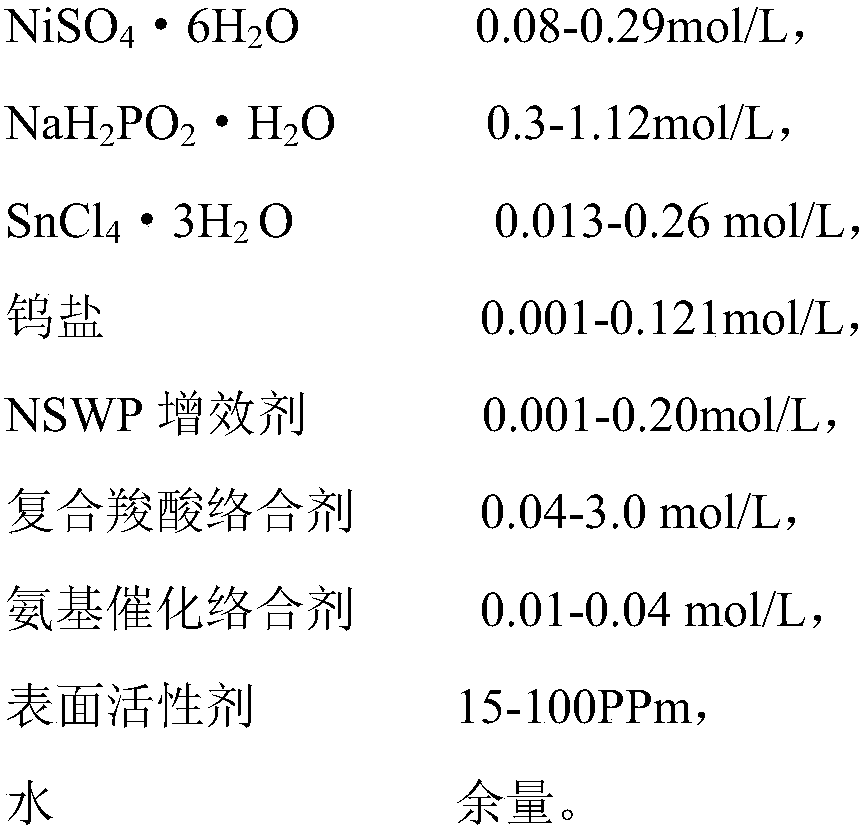

Method used

Image

Examples

Embodiment 1

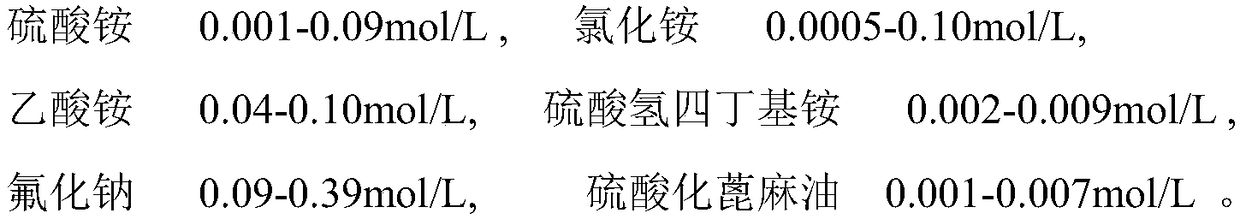

[0071] The NSWP synergist used in embodiment 1 consists of:

[0072] Ammonium sulfate 0.0455mol / L, ammonium chloride 0.0502mol / L,

[0073] Ammonium acetate 0.07mol / L, tetrabutylammonium hydrogen sulfate 0.0055mol / L,

[0074] Sodium fluoride 0.24mol / L, sulfated castor oil 0.004mol / L.

Embodiment 2

[0075] The NSWP synergist used in embodiment 2 consists of:

[0076] Ammonium sulfate 0.0455mol / L, ammonium chloride 0.0502mol / L,

[0077] Ammonium acetate 0.07mol / L, tetrabutylammonium hydrogen sulfate 0.0055mol / L,

[0078] Sodium fluoride 0.24mol / L, sulfated castor oil 0.004mol / L.

Embodiment 3

[0079] The NSWP synergist used in embodiment 3 consists of:

[0080] Ammonium sulfate 0.065mol / L, ammonium chloride 0.0880mol / L,

[0081] Ammonium acetate 0.08mol / L, tetrabutylammonium hydrogen sulfate 0.0035mol / L,

[0082] Sodium fluoride 0.14mol / L, sulfated castor oil 0.006mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com