Method for preparing bulk phase aluminum-doped cobaltosic oxide

A technology of cobalt tetroxide and cobalt hydroxide, applied in the field of lithium ion batteries, can solve the problems of uneven distribution of aluminum elements, low production efficiency, uneven precipitation of aluminum and cobalt, etc., to promote rapid growth, prevent oxidation, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

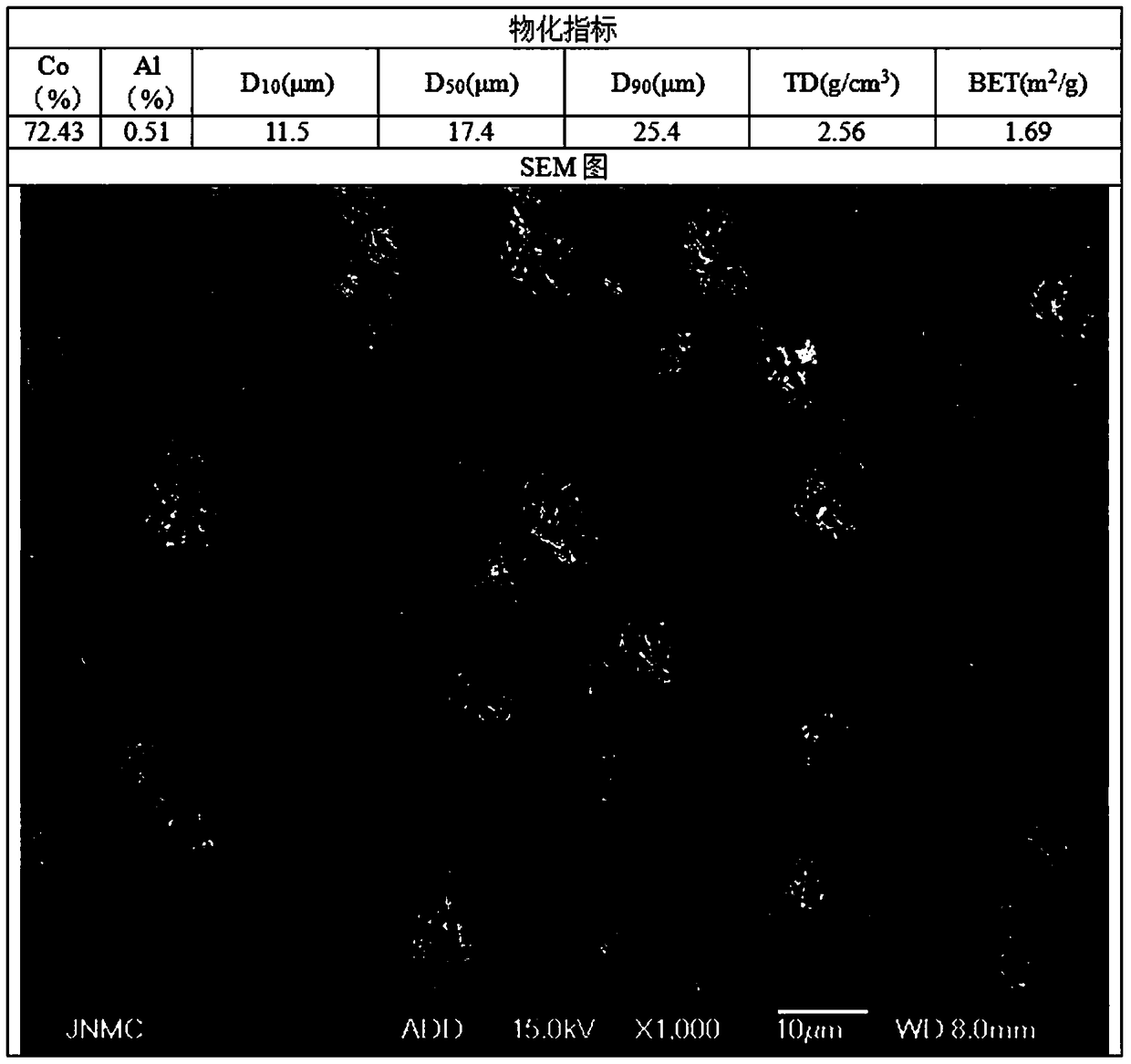

Embodiment 1

[0032] Prepare a cobalt chloride solution with a concentration of 1mol / L as solution A; prepare a sodium hydroxide solution with a concentration of 2mol / L as solution B; prepare an ammonia solution with a concentration of 5mol / L, and add 5mL volume fraction per liter of ammonia solution The 30% hydrazine hydrate solution is the C solution; the hydrogen peroxide solution with a concentration of 5mol / L is prepared as the D solution; the concentration of 4g / L aluminum trichloride anhydrous ethanol solution is prepared as the E solution.

[0033] At the beginning of the synthesis reaction, the A solution, the B solution and the C solution flow into the reactor simultaneously, and at the same time, the E solution feeding pipe is divided into 6-9 small pipes, and the liquid outlet of each fine feeding pipe is fixed to the reactor for stirring Add E solution to the middle or tail of the paddle, and react under the stirring state of 500r / min. During the reaction, control the reaction p...

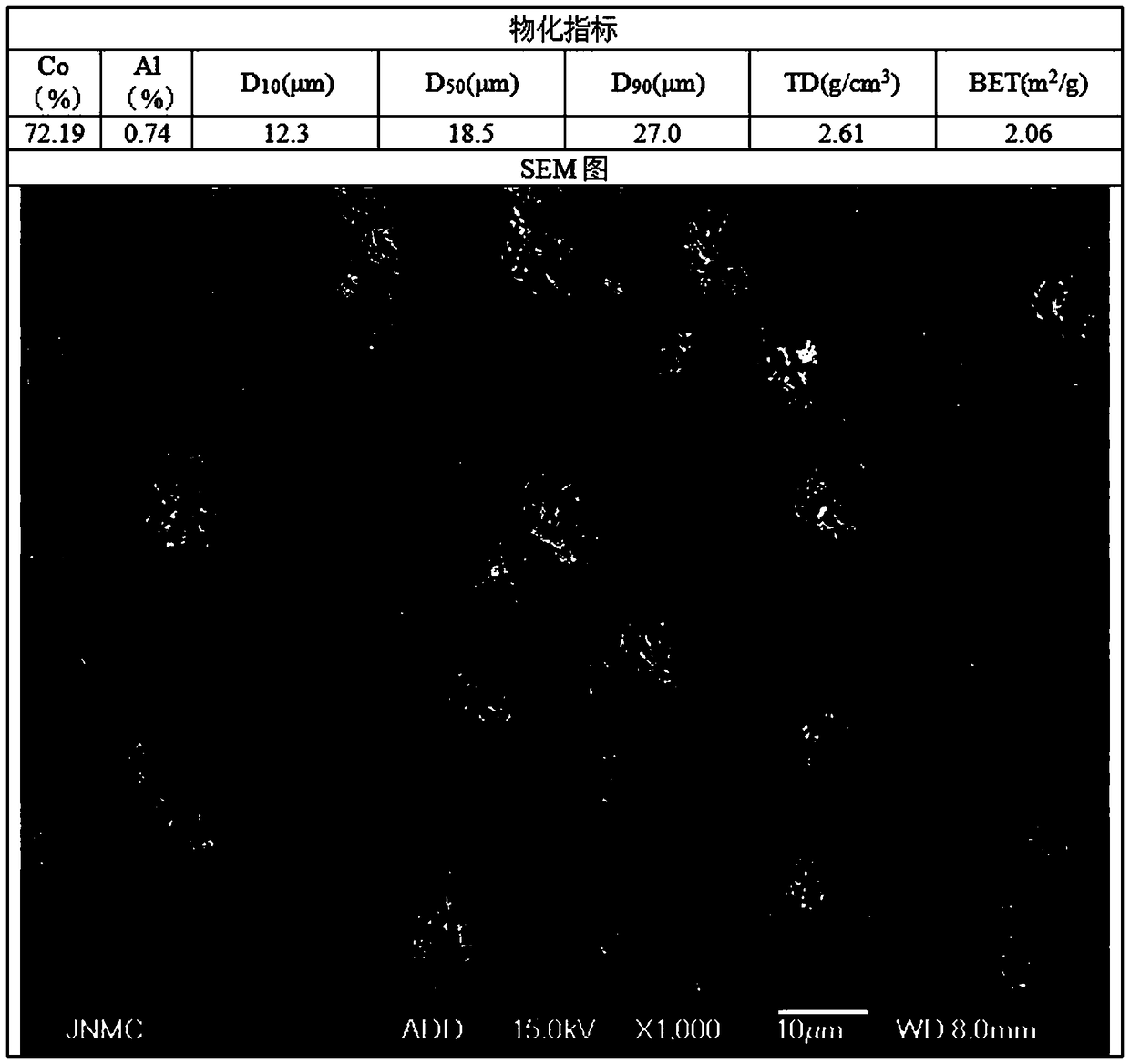

Embodiment 2

[0038] Prepare a cobalt sulfate solution with a concentration of 1.5mol / L as solution A; prepare a sodium hydroxide solution with a concentration of 4mol / L as solution B; prepare an ammonia solution with a concentration of 8mol / L, and add 15mL volume fraction per liter of ammonia solution A 30% hydrazine hydrate solution is solution C; a hydrogen peroxide solution with a concentration of 6 mol / L is prepared as solution D; an aluminum nitrate absolute ethanol solution with a concentration of 6 g / L is prepared as solution E.

[0039] At the beginning of the synthesis reaction, the A solution, the B solution and the C solution flow into the reactor simultaneously, and at the same time, the E solution feeding pipe is divided into 6-9 small pipes, and the liquid outlet of each fine feeding pipe is fixed to the reactor for stirring Add E solution to the middle or tail of the paddle, and react under the stirring state of 400r / min. During the reaction, the pH value of the reaction is con...

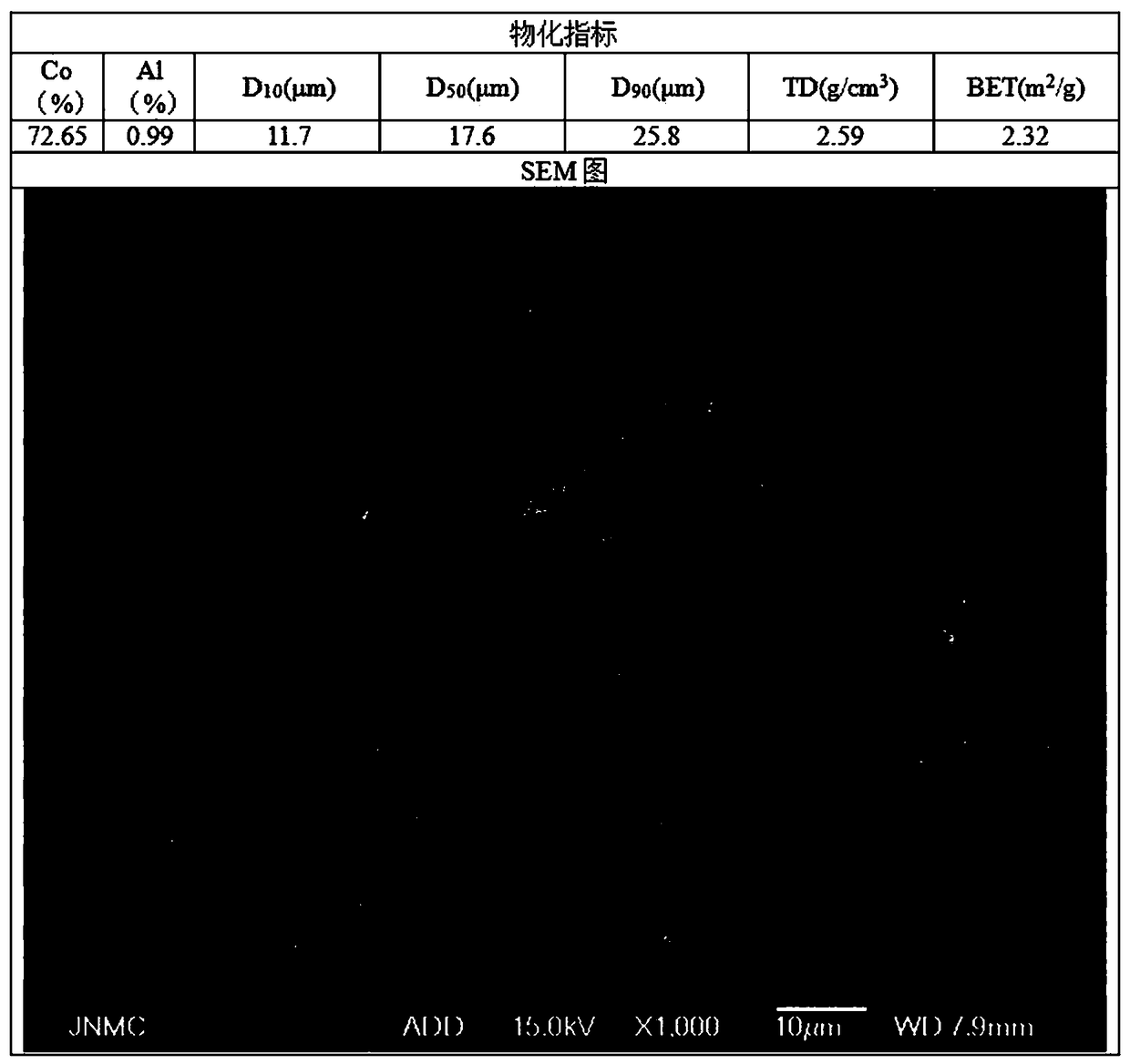

Embodiment 3

[0044] Prepare the cobalt nitrate solution with a concentration of 2mol / L as solution A; prepare the sodium hydroxide solution with a concentration of 6mol / L as solution B; The 30% hydrazine hydrate solution is solution C; the hydrogen peroxide solution with a concentration of 8 mol / L is prepared as solution D; the aluminum trichloride absolute ethanol solution with a concentration of 8 g / L is prepared as solution E.

[0045] At the beginning of the synthesis reaction, the A solution, the B solution and the C solution flow into the reactor simultaneously, and at the same time, the E solution feeding pipe is divided into 6-9 small pipes, and the liquid outlet of each fine feeding pipe is fixed to the reactor for stirring Add E solution to the middle or tail of the paddle, and react under the stirring state of 300r / min. During the reaction, control the pH value of the reaction to 9.0, the reaction temperature is 80°C, the flow rate of A solution is 300L / h, and the flow rate of B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com