Cement set retarder

A cement retarder and additive technology, applied in the field of cement retarders, can solve the problems of short retardation time and great influence on cement strength, and achieve the effects of prolonging retardation time, improving fluidity and improving crosslinking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

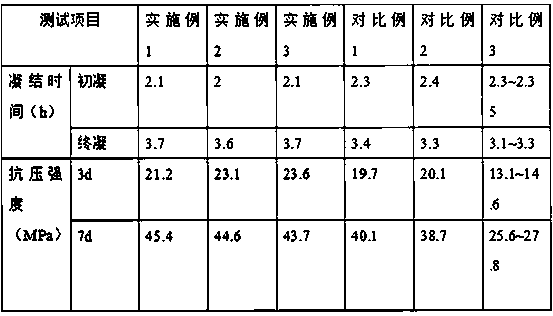

Examples

preparation example Construction

[0031] The preparation method of composite retarding component A comprises the steps:

[0032] (1) Take mica, Glauber's salt and diphenylmethane diisocyanate in a ball milling tank according to the mass ratio of 5:2~3:1, add zirconia ball milling beads according to the mass ratio of the ball to material 15~20:1, and heat at 5~10°C Ball milling at 300~350r / min for 3~5h to obtain ball milling materials for later use;

[0033] (2) In terms of parts by mass, take 10~15 parts of nano-calcium carbonate, 10~20 parts of linoleic acid, 8~20 parts of carbomer, and 35~50 parts of water and mix them in a container at a rate of 8~12mL / min Under argon protection, stir at 400-600r / min for 45-60min at 70-85°C, add a pH regulator to adjust the pH to neutral, and vacuum dehydrate at 50-70°C to obtain nano-calcium carbonate dispersion;

[0034] (3) According to the mass ratio of 3~5:4:3:15~20, take the spare ball mill, nano-calcium carbonate dispersion, phospholipid, and absolute ethanol and mi...

Embodiment 1

[0043] Auxiliary: Mix calcium carbide slag, red mud and water according to the mass ratio of 3:1:10, stir magnetically at 300r / min for 20min, add 30% of the mass of calcium carbide slag in H 2 o 2 Let it stand for 4 hours, filter, and take the filter residue and dry it in an oven at 60°C to obtain the additive.

[0044] Surfactant: sodium dodecylbenzenesulfonate.

[0045] Coating solution: Mix 10% acetic acid solution, chitosan, sodium carboxymethyl starch, and microcrystalline paraffin at a mass ratio of 10:1:3:1, and stir at 450r / min for 30 minutes to obtain the coating solution .

[0046] pH regulator: Mix sodium carbonate and NaOH solution with a concentration of 0.1mol / L at a mass ratio of 3:1 to obtain a pH regulator.

[0047] Glycoprotein liquid: in parts by weight, take 20 parts of bovine serum albumin, 0.1 part of trypsin, and 100 parts of water in turn, mix them at 40°C, stir at a constant temperature of 400r / min for 45min, heat up to 80°C, and keep warm to inacti...

Embodiment 2

[0061] Auxiliary: Mix calcium carbide slag, red mud and water at a mass ratio of 3:1:15, stir magnetically at 450r / min for 45min, add 55% of the mass of calcium carbide slag in H 2 o 2 Let it stand for 8 hours, filter, and take the filter residue and dry it in an oven at 75°C to obtain the additive.

[0062] Surfactant: Sodium Lauryl Sulfate.

[0063] Coating solution: Mix 10% acetic acid solution, chitosan, sodium carboxymethyl starch, and microcrystalline paraffin at a mass ratio of 15:1:3:1, and stir at 600r / min for 50min to obtain the coating solution .

[0064] pH regulator: Mix sodium carbonate and NaOH solution with a concentration of 0.1mol / L at a mass ratio of 5:1 to obtain a pH regulator.

[0065] Glycoprotein liquid: in parts by weight, take 30 parts of bovine serum albumin, 0.3 parts of trypsin, and 200 parts of water in sequence, mix them at 45°C, stir at a constant temperature of 500r / min for 60min, heat up to 95°C, and keep warm to inactivate the enzyme Afte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap