Waterproof paint with improved hydrophobic property

A waterproof coating and hydrophobic technology, applied in the field of coatings, can solve the problems of poor chemical stability, poor compatibility, and low weather resistance of coatings, and achieve the effect of improving stability, weather resistance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

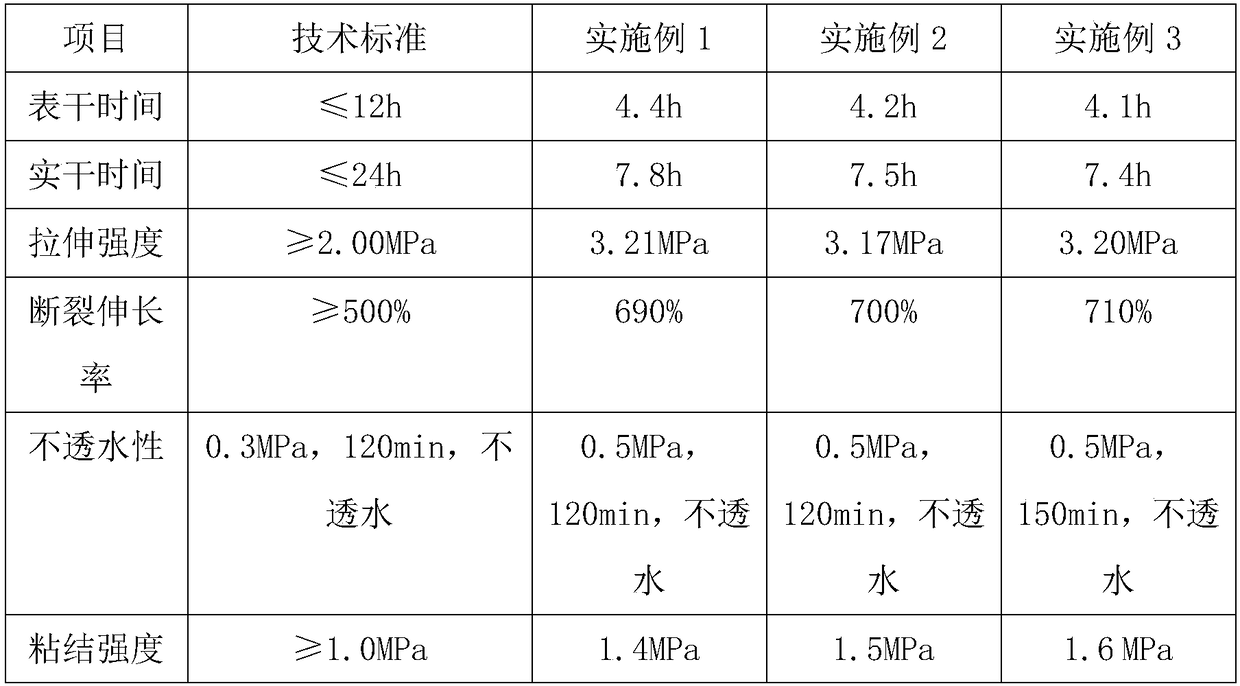

Examples

Embodiment 1

[0026] A waterproof coating with improved hydrophobicity. According to the parts by mass, the waterproof coating contains the following components: 40 parts of amino-terminated polyether, 20 parts of hydroxyl-terminated polyether, 15 parts of isocyanate, 1 part of dioctyl phthalate, 2 parts of chain extender, 18 parts of hydrophobic modified filler, 1 part of catalyst, 6 parts of cyclohexane, 1.3 parts of silane coupling agent, and 2 parts of auxiliary agent.

[0027] The inorganic filler contained in the hydrophobic modified filler is kaolin, talc and light calcium carbonate.

[0028] In the present invention, the preparation method of the hydrophobic modified filler is to prepare the following raw materials in parts by mass: 45 parts of kaolin, 32 parts of talcum powder, 18 parts of light calcium carbonate, 3 parts of organosilane coupling agent, 4 parts of stearic acid 17 parts, 17 parts of ethylene glycol, 6 parts of acetic acid, mix organic silane coupling agent and stear...

Embodiment 2

[0035] A waterproof coating with improved hydrophobicity. According to the parts by mass, the waterproof coating contains the following components: 50 parts of amino-terminated polyether, 35 parts of hydroxyl-terminated polyether, 20 parts of isocyanate, 2 parts of dioctyl phthalate, 3 parts of chain extender, 23 parts of hydrophobic modified filler, 3 parts of catalyst, 8 parts of cyclohexane, 1.6 parts of silane coupling agent, and 5 parts of auxiliary agent.

[0036] The inorganic filler contained in the hydrophobic modified filler is kaolin, talc and light calcium carbonate.

[0037]In the present invention, the preparation method of the hydrophobic modified filler is to prepare the following raw materials in parts by mass: 45 parts of kaolin, 32 parts of talcum powder, 18 parts of light calcium carbonate, 3 parts of organosilane coupling agent, 4 parts of stearic acid 17 parts, 17 parts of ethylene glycol, 6 parts of acetic acid, mix organic silane coupling agent and stea...

Embodiment 3

[0044] A waterproof coating with enhanced hydrophobicity. According to the parts by mass, the waterproof coating contains the following components: 45 parts of amino-terminated polyether, 30 parts of hydroxyl-terminated polyether, 18 parts of isocyanate, 1.5 parts of dioctyl phthalate, 2.5 parts of chain extender, 20 parts of hydrophobically modified filler, 2 parts of catalyst, 7 parts of cyclohexane, 1.5 parts of silane coupling agent, and 4 parts of auxiliary agent.

[0045] The inorganic filler contained in the hydrophobic modified filler is kaolin, talc and light calcium carbonate.

[0046] In the present invention, the preparation method of the hydrophobic modified filler is to prepare the following raw materials in parts by mass: 45 parts of kaolin, 32 parts of talcum powder, 18 parts of light calcium carbonate, 3 parts of organosilane coupling agent, 4 parts of stearic acid 17 parts, 17 parts of ethylene glycol, 6 parts of acetic acid, mix organic silane coupling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com