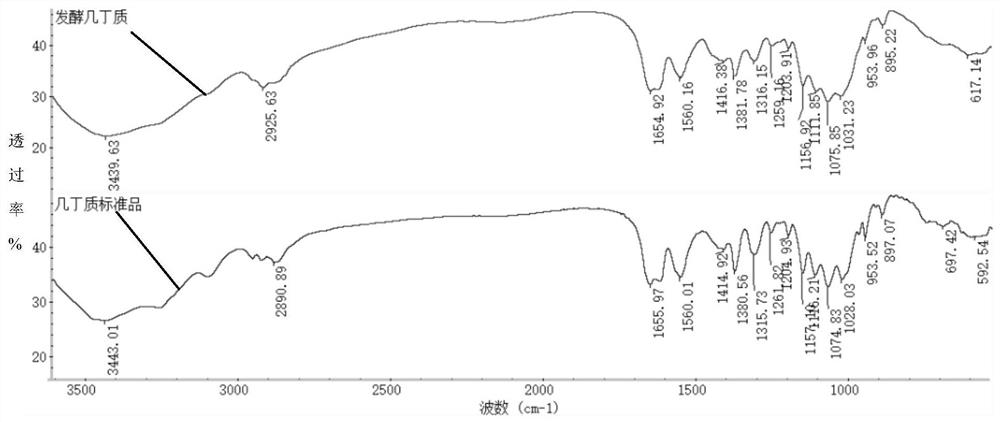

A method for preparing chitin by fermentation

A technology of chitin and fermentation medium, applied in the field of bioengineering, can solve the problems of difficult industrialization, high cost, and low yield, and achieve the effects of stable product quality, low production cost, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preserved strain of the present invention is isolated from farmland soil in Fengxian District, Shanghai, and separated by 6 generations of streaking to obtain the pure strain MF010. The biological characteristics of the strain are: the diameter of the colony is about 4.5cm; the mycelium is white, and a large number of light yellow to yellow spores grow on the surface of the colony after maturity; the colony is velvety, with radial grooves; no exudate; red. Conidia and conidiophores are yellow; conidia are nearly spherical and slightly rough; the surface of the colony is fully fertile; the optimum growth temperature is 28°C; aerobic; after molecular biological analysis of the 18sDNA conserved sequence of the strain, it was compared with GenBank Compared with the 18S rDNA sequence homology, it was found that the highest similarity with Aspergillus strains reached 99%, and it was identified as Aspergillus ochraceus. On April 25, 2018, the deposit number is CGMCC No.15...

Embodiment 2

[0030] (1) Incline cultivation

[0031]Draw a certain amount of bacterial solution evenly on the slant culture medium under aseptic operation to absorb the bacterial species preserved in the glycerol tube, and culture at a constant temperature of 28°C for 5-7 days. In the slant medium used, each liter of medium contains 200g of peeled potatoes, 20g of glucose, and 20g of agar, with a pH of 6.4-6.6; the above-mentioned medium is sterilized at 121°C for 30 minutes, and used after cooling.

[0032] (2) Seed cultivation

[0033] The seed medium used contained 8g of sucrose, 8g of yeast extract, and 2.0g of molasses per liter of medium, with a pH of 6.0; the above-mentioned medium was sterilized at 121°C for 30 minutes, and used after cooling.

[0034] Scrape the yellow spores from the slant bacteria in step (1) under aseptic operation and transfer them to sterile saline, and adjust the spore concentration to 4.0-7.0×10 8 spores / ml, then transferred to sterilized seed medium acco...

Embodiment 3

[0042] (1) Incline culture and seed culture

[0043] As in previous example 1

[0044] (2) Fermentation culture

[0045] The fermentation medium used contains 30g of sucrose, 20g of yeast extract, 8g of soybean powder, 1.0g of molasses, and 1.5g of K in every liter of medium. 2 HPO 4 , 1.4g MgSO 4 ·7H 2 O, 0.01 g FeSO 4 ·7H 2 O, 1.5 g NaH 2 PO 4 12H 2 O, pH 5.5; the above-mentioned medium was sterilized at 121°C for 30 minutes by moist heat, and then used after cooling.

[0046] Prepare 10 bottles of fermentation shake flasks with a volume of 250ml (each fermentation bottle contains 90ml sterile medium), in each fermentation shake flask, add a mass percent concentration of 20% hydrogen peroxide solution, add 0.8% per liter of culture medium The hydrogen peroxide solution of 1 ml, shake well, absorb 10 ml of the seed liquid cultivated in the step (2) and inoculate it in the fermentation shaker flask (10% inoculum size) aseptically, place it in a constant temperature s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com