Degradable curcumin derivative-polylactic acid-polyglycolic acid composite film, and preparation method thereof

A technology of curcumin derivatives and polyglycolic acid, which is applied in the direction of drug combination, medical preparations of non-active ingredients, drug delivery, etc., can solve the problem of curcumin derivatives-polylactic acid-polyglycolic acid copolymer composite film that has not yet been involved Preparation methods and other issues to achieve excellent two-photon fluorescence performance, good imaging of biological cells, and enhanced optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 2 grams of polylactic acid and 3 grams of polyglycolic acid are completely dissolved in 50 mL of chloroform;

[0033] (2) Heat, stir and control the temperature at 70°C, keep warm for 1.0h, evaporate the solvent under reduced pressure, wash and dry in vacuum to obtain white polylactic acid-polyglycolic acid (PLGA) powder;

[0034] (3) Weigh 0.2 grams of curcumin derivatives (L) and 1.8 grams of PLGA and dissolve them in 40 mL of chloroform, ultrasonically disperse them at 50°C for 1 hour and place them in a petri dish, and obtain uniform curcumin derivatives after the solvent evaporates - Polylactic acid-polyglycolic acid composite film (L-PLGA);

[0035] (4) The composite membrane was washed several times with ethanol and water respectively, and dried in a vacuum oven at 50° C. to obtain 10% solid object.

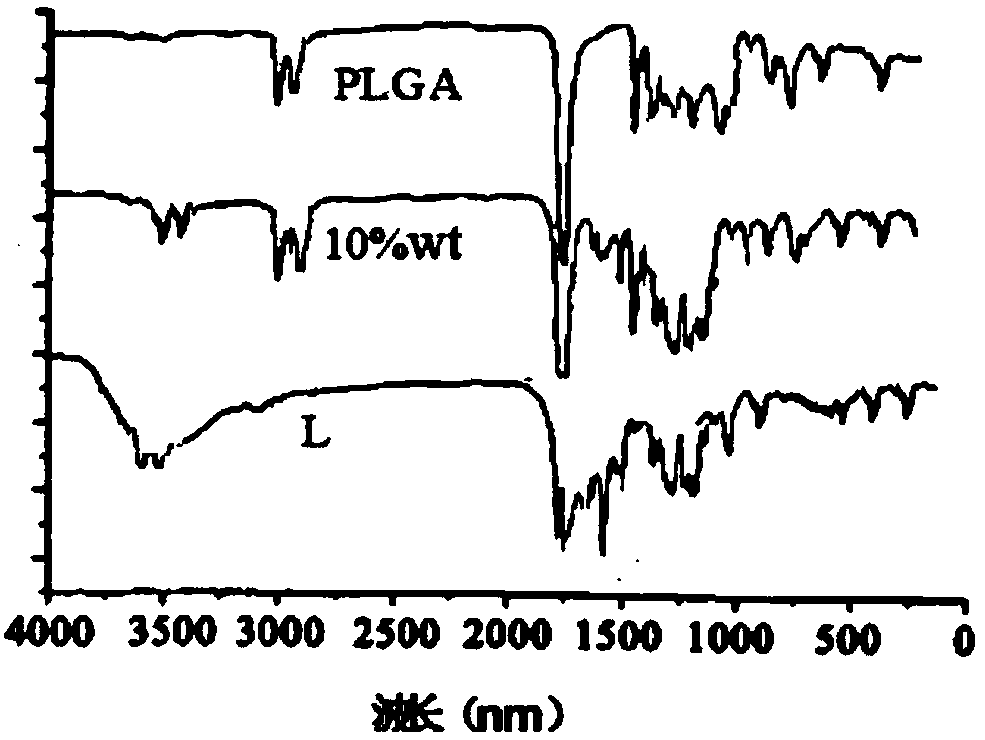

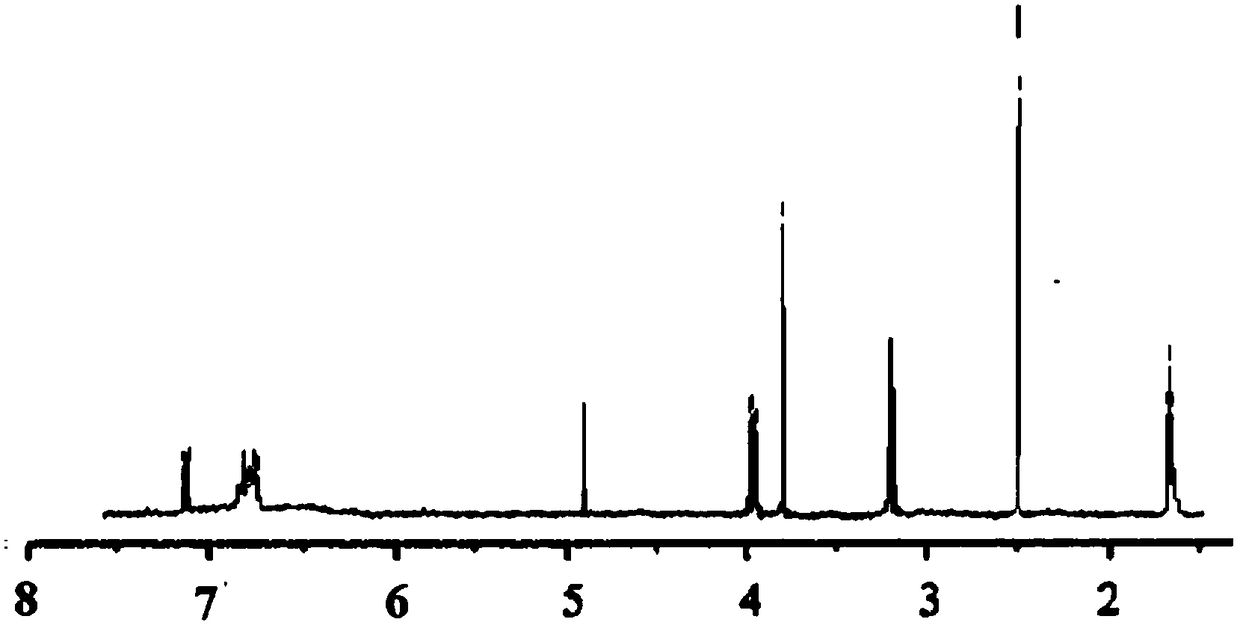

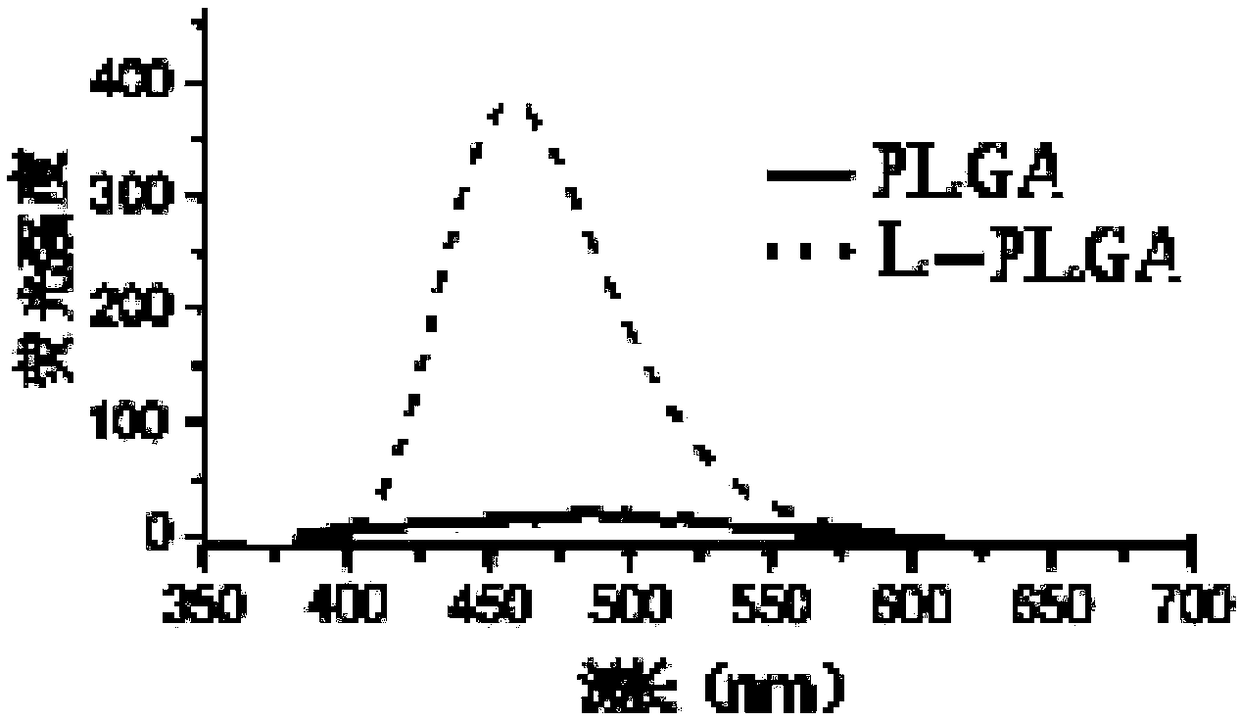

[0036] The experimental characteristics of the obtained target product refer to figure 1 — Image 6 As shown, specifically:

[0037] figure 1 The infrared ...

Embodiment 2

[0043] (1) 2 grams of polylactic acid and 3 grams of polyglycolic acid were completely dissolved in 50 mL of chloroform and 1,4-dioxane mixed solvent;

[0044] (2) Heat, stir and control the temperature at 60°C, keep warm for 1.5h, evaporate the solvent under reduced pressure, wash and dry in vacuum to obtain PLGA white powder;

[0045] (3) Weigh 0.4 g of curcumin derivative (L) and 3.8 g of PLGA, dissolve them in 80 mL of chloroform and 1,4-dioxane mixed solvent, and place them in a petri dish after ultrasonic dispersion at 60°C for 1.0 hour After the solvent evaporates, a uniform curcumin derivative-polylactic acid-polyglycolic acid composite film (L-PLGA) is obtained;

[0046] (4) The composite membrane was washed several times with ethanol and water respectively, and dried in a vacuum oven at 50° C. to obtain the solid object.

[0047] The experimental properties of the target product obtained in this embodiment 2 can also refer to Figure 1-Figure 6 Shown, not detailed....

Embodiment 3

[0049] (1) 3 grams of polylactic acid and 2 grams of polyglycolic acid are completely dissolved in 50 mL of tetrahydrofuran solvent;

[0050] (2) Heat, stir and control the temperature at 70°C, keep warm for 2.0 hours, evaporate the solvent under reduced pressure, wash and dry in vacuum to obtain PLGA white powder;

[0051] (3) Weigh 0.3 grams of curcumin derivatives (L) and 2.0 grams of PLGA and dissolve them in 40 mL of tetrahydrofuran solvent, and place them in a petri dish after reflux reaction at 80 ° C for 3.0 hours, and obtain uniform curcumin after the solvent evaporates Derivatives-polylactic acid-polyglycolic acid composite film (L-PLGA);

[0052] (4) The composite membrane was washed several times with ethanol and water respectively, and dried in a vacuum oven at 50° C. to obtain the solid object.

[0053] The experimental characteristics of the target product obtained in this embodiment 3 can also refer to Figure 1-Figure 6 Shown, not detailed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com