Three-dimensional graphene/Fe3O4 magnetic nanometer adsorption material

An adsorption material and magnetic nano technology, which is applied in the direction of adsorption of water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult separation and low adsorption capacity, and achieve low cost and excellent preparation method Simple, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of 3D-MG

[0024] 40mg of graphene oxide was peeled off in deionized water for 20min by sonication to prepare graphene oxide dispersion, and then 110mg of FeCl was added 3 ·6H 2 O was ultrasonically dissolved, and 200mg of L-Cys was added, and 1mL of ammonia water was quickly added to adjust the pH of the reaction solution to alkaline; the reactant was stirred at 95°C for 3 hours to obtain a magnetic black precipitate; after cooling to room temperature, hysteresis separation , the black precipitate was repeatedly washed with deionized water and absolute ethanol and freeze-dried for 24 hours to obtain magnetic graphene powder.

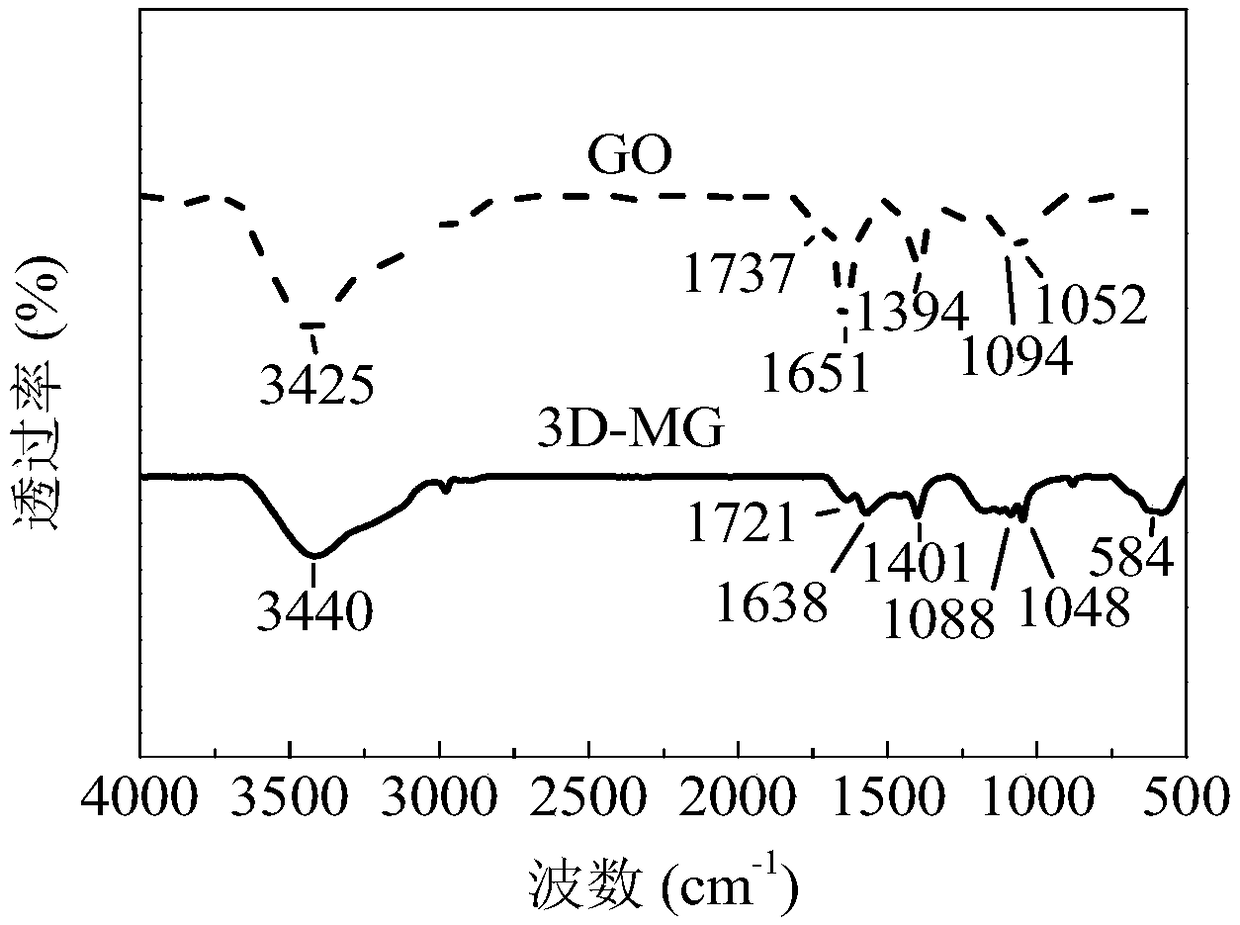

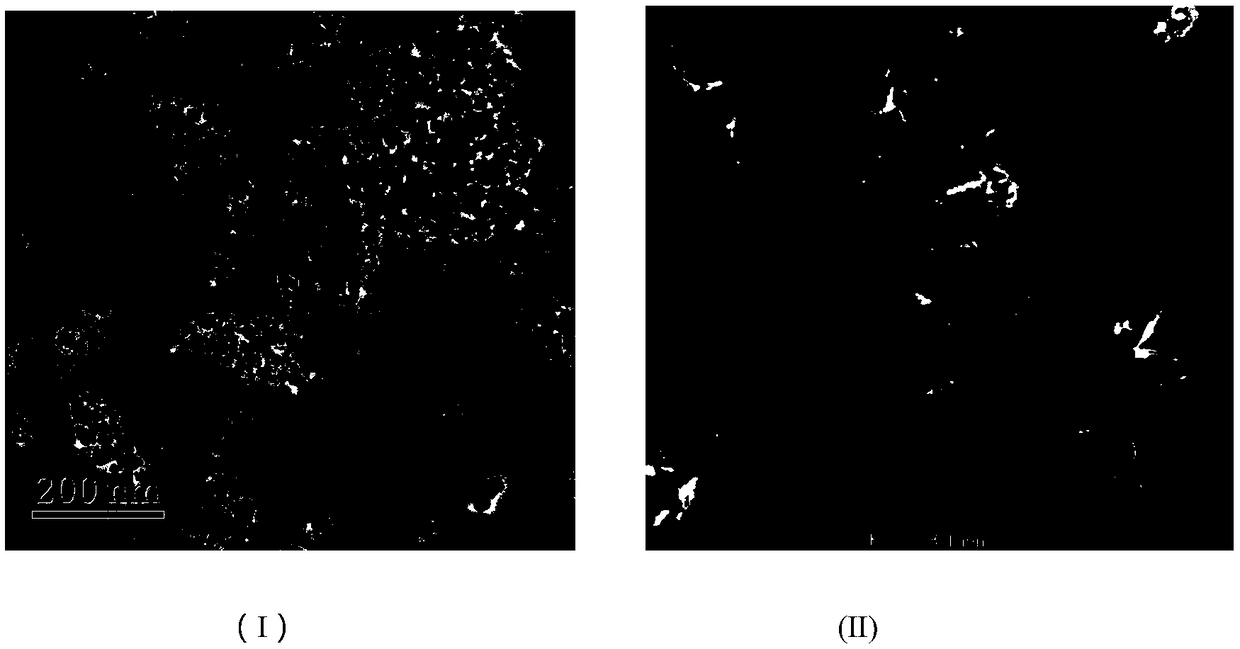

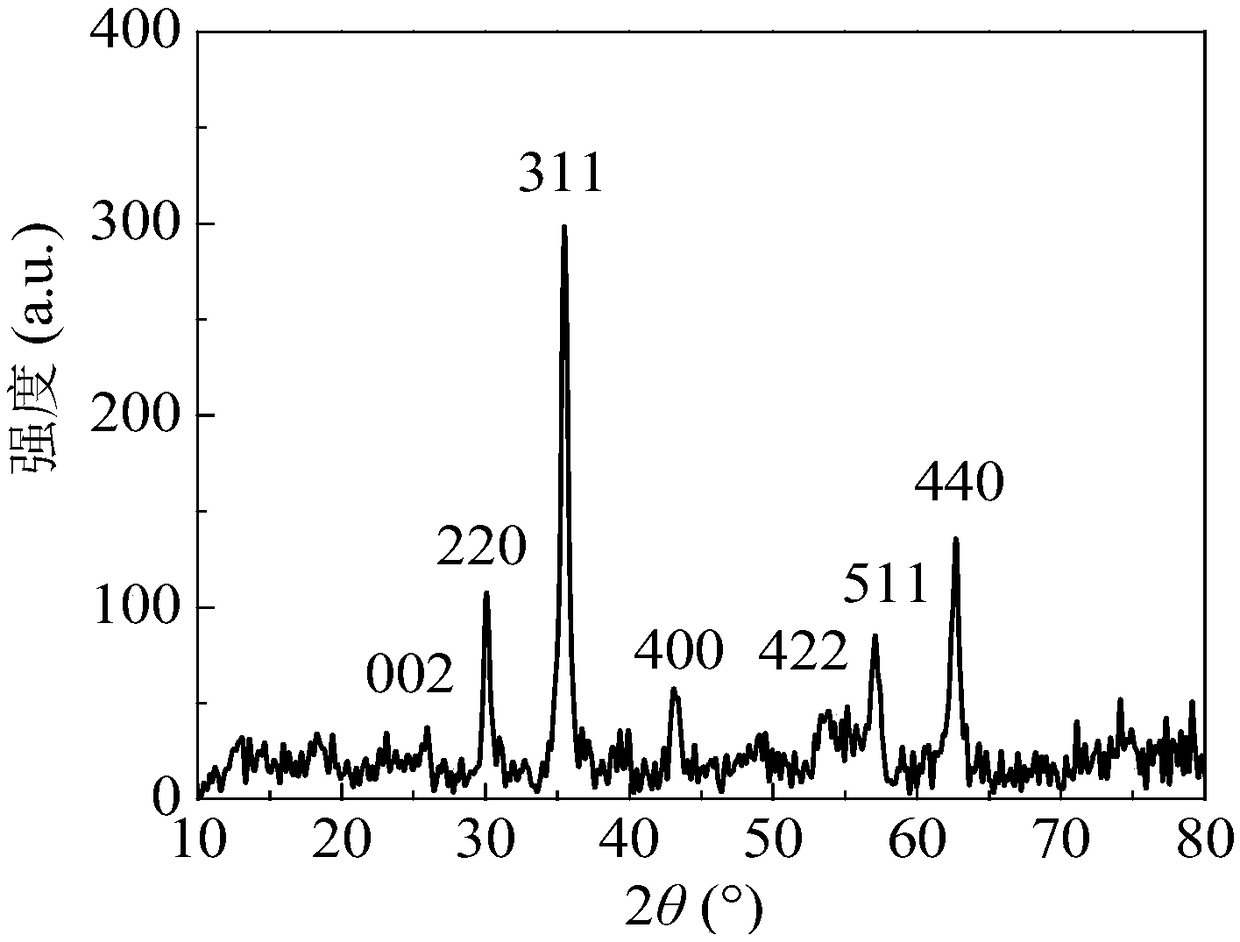

[0025] From figure 1 The infrared spectrum shows that in the infrared spectrum of GO, 3425cm -1 The strong broad peak corresponds to the stretching vibration of -OH, 1737cm -1 The corresponding peak at is the stretching vibration of C=O, 1651cm -1 The peak corresponds to the stretching vibration of aromatic C=C, 139...

Embodiment 2

[0032] Embodiment 2:3D-MG is to the adsorption of the dyestuff of different ionic type

[0033] (1) Effect of pH on the adsorption performance of 3D-MG

[0034] Determination of before and after adsorption of methylene blue, Congo red and neutral red (2×10-5M) by 3D-MG under pure water and different pH (3-10) (add 0.001mol / L NaCl, then adjust pH with HCl and NaOH) The absorbance of 3D-MG was investigated to explore the effect of pH on the adsorption performance of 3D-MG.

[0035] (2) Effect of ionic strength on the adsorption performance of 3D-MG

[0036] The absorbance of 3D-MG before and after adsorption of methylene blue, Congo red and neutral red in NaCl solution at different concentrations (0, 0.01, 0.1, 0.5, 1, 2mol / L) was measured to explore the effect of ionic strength on the adsorption performance of 3D-MG. influences.

[0037] (3) Standard curves and linear ranges of methylene blue, Congo red and neutral red

[0038] Prepare stock solutions (2×10-3M) of three dye...

Embodiment 3

[0049] Embodiment 3: investigation of desorption and reuse situation

[0050] The complex uses absolute ethanol as the eluent, after ultrasonic oscillation for 10 minutes, hysteresis separation, and then washes three times with secondary water and absolute ethanol respectively, and vacuum-dries at 60°C to obtain the desorbed magnetic nanocomposite, which is then recycled. use. This cycle was repeated three times, and the adsorption amounts of MB, CR, and NR by 3D-MG were calculated in each cycle.

[0051] Depend on Figure 12 It can be seen that after 3D-MG was reused 4 times, the adsorption capacity only decreased slightly, indicating that 3D-MG is a reusable dye adsorption material. It shows that the complex has a good application prospect in environmental water purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com