A kind of halogen-free flame-retardant polyethylene material and preparation method thereof

A technology of flame-retardant polyethylene and vinyltriethoxysilane, which is applied in the field of halogen-free flame-retardant polyethylene materials and its preparation, can solve the problems of low flame-retardant efficiency, large addition amount, and easy migration, and achieve good Antistatic properties, maintaining mechanical properties, and improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

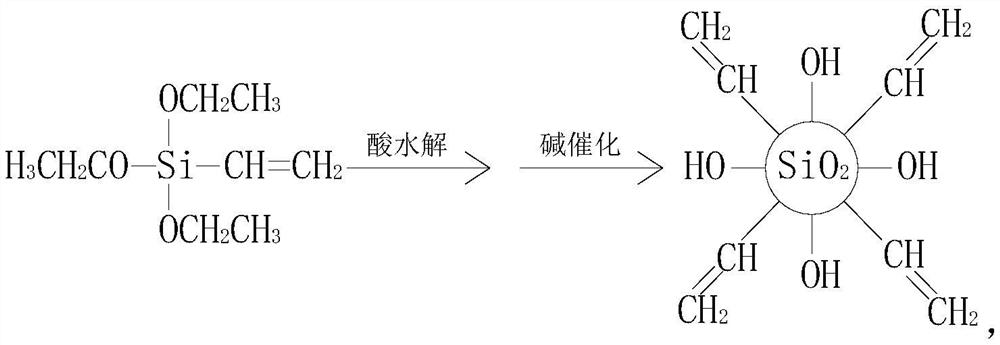

[0031] (1) Preparation of vinyl-containing hybrid silicon spheres: put 0.9 g of vinyltriethoxysilane (VTES) in a flask filled with 50 mL of distilled water, add hydrochloric acid to adjust the pH value of the solution in the flask to 3-5, Hydrolyze VTES for 1-3 hours; add ammonia water with a mass concentration of 25% to adjust the pH value of the liquid in the flask to 10-13, carry out alkali-catalyzed condensation reaction for 2-5 hours, and centrifuge the product for 5-20 minutes (2000-3000rpm), The lower precipitate was taken out and dried to obtain vinyl-containing hybrid silicon spheres.

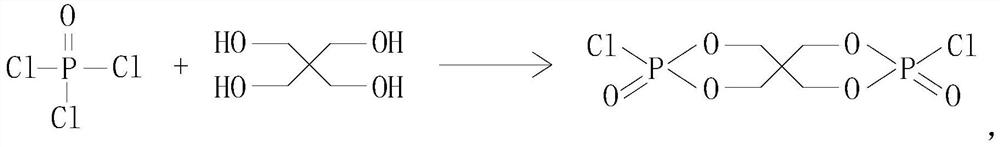

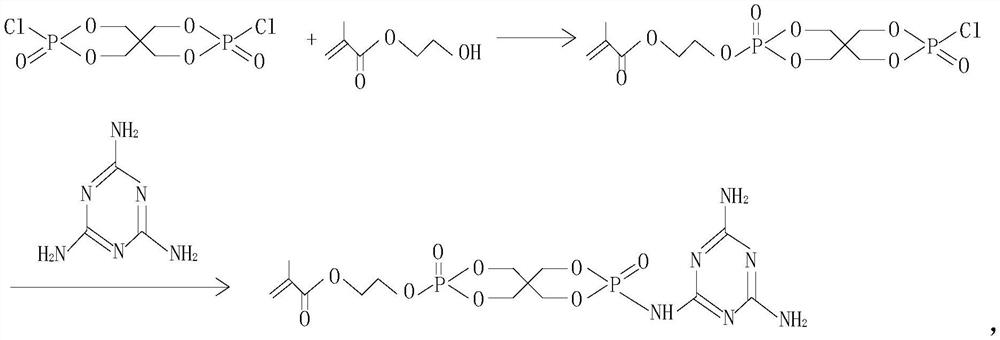

[0032](2) Preparation of EADP: ①Add pentaerythritol (PER) (63.00g, 0.5mol), phosphorus oxychloride (270m L, 3.0mol), stirred and heated slowly. When the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com