Diatom ooze coating capable of degrading formaldehyde for indoor decoration

A technology for diatom mud coating and interior decoration, which is applied to coatings, inorganic raw material rayon, etc., can solve problems such as low utilization rate of visible light, and achieve the effects of solving poor degradation effect, improving adsorption capacity, and improving adsorption activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

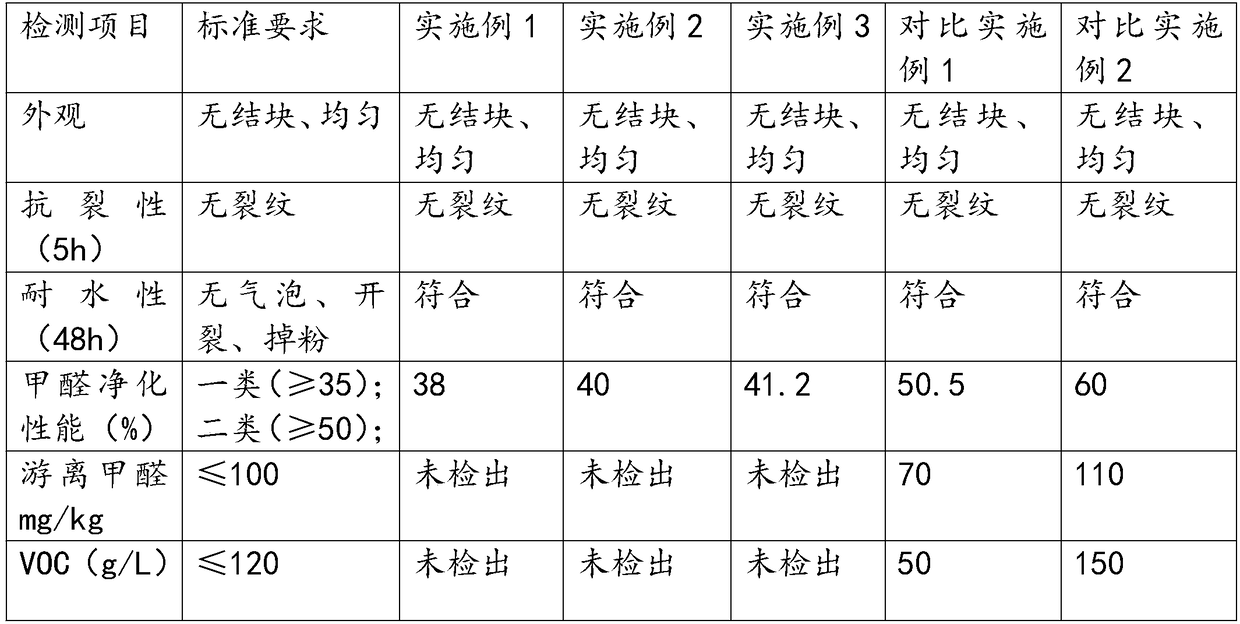

Examples

Embodiment 1

[0034] A formaldehyde-degradable diatom mud coating for interior decoration, each raw material composition (total mass 100kg): activated diatomite 15%, composite photocatalyst 10%, bamboo charcoal fiber 3%, polyacrylic resin 20%, ethylene-acetic acid Vinyl ester copolymer 10%, carborundum 5%, zinc stearate 0.5%, the balance is water;

[0035] The preparation method of the described activated diatomite is as follows: 100kg of diatomite is added to a ball mill for grinding and pulverizing, adding water to prepare a diatomite solution with a concentration of 30%, adding 45% concentrated nitric acid solution while stirring, and detecting The pH of the diatomite solution is 2.5, stop adding concentrated nitric acid, continue to stir for 15 minutes, measure the pH of the diatomite solution again to be 2.6, let it stand at 35°C for 3 hours, cool to room temperature, filter and wash until neutral, and dry The filter residue is put into a muffle furnace, calcined at 700°C for 5 hours, ...

Embodiment 2

[0044] A formaldehyde-degradable diatom mud coating for interior decoration, each raw material composition (total mass 100kg): activated diatomite 25%, composite photocatalyst 10%, bamboo charcoal fiber 6%, polyacrylic resin 30%, ethylene-acetic acid Vinyl ester copolymer 5%, carborundum 2%, zinc stearate 0.5%, the balance is water;

[0045] Preparation of Activated Diatomite and CeO 2 -WO 3 The preparation of composite photocatalyst is with embodiment 1;

[0046] A kind of preparation method of diatom ooze coating for interior decoration that can degrade formaldehyde, specifically comprises the following steps:

[0047] S1. After mixing the activated diatomite and the composite photocatalyst, add it to the ball mill, and mix it by mechanical extrusion for 5 hours, so that the composite photocatalyst is fully loaded in the activated diatomite layer, thereby reducing the particle size of the diatomite , while increasing the specific surface area of diatomite and composite ...

Embodiment 3

[0050] A formaldehyde-degradable diatom mud coating for interior decoration, each raw material composition (total mass 100kg): activated diatomite 20%, composite photocatalyst 12%, bamboo charcoal fiber 5%, polyacrylic resin 25%, ethylene-acetic acid Vinyl ester copolymer 6%, carborundum 4%, zinc stearate 1%, the balance is water;

[0051] Preparation of Activated Diatomite and CeO 2 -WO 3 The preparation of composite photocatalyst is with embodiment 1;

[0052] A kind of preparation method of diatom ooze coating for interior decoration that can degrade formaldehyde, specifically comprises the following steps:

[0053] S1. After mixing the activated diatomite and the composite photocatalyst, add it to the ball mill, and mix it by mechanical extrusion for 6 hours, so that the composite photocatalyst is fully loaded in the activated diatomite layer, thereby reducing the particle size of the diatomite , while increasing the specific surface area of diatomite and composite ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com