A kind of imitation wood composite paint and preparation method thereof

A composite paint and imitation wood technology, applied in the field of paint, can solve the problems of poor weather resistance and flame retardancy, loss of "imitation wood" value, poor adhesion, etc., to achieve realistic real wood effects, improve anti-settling performance, and improve dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

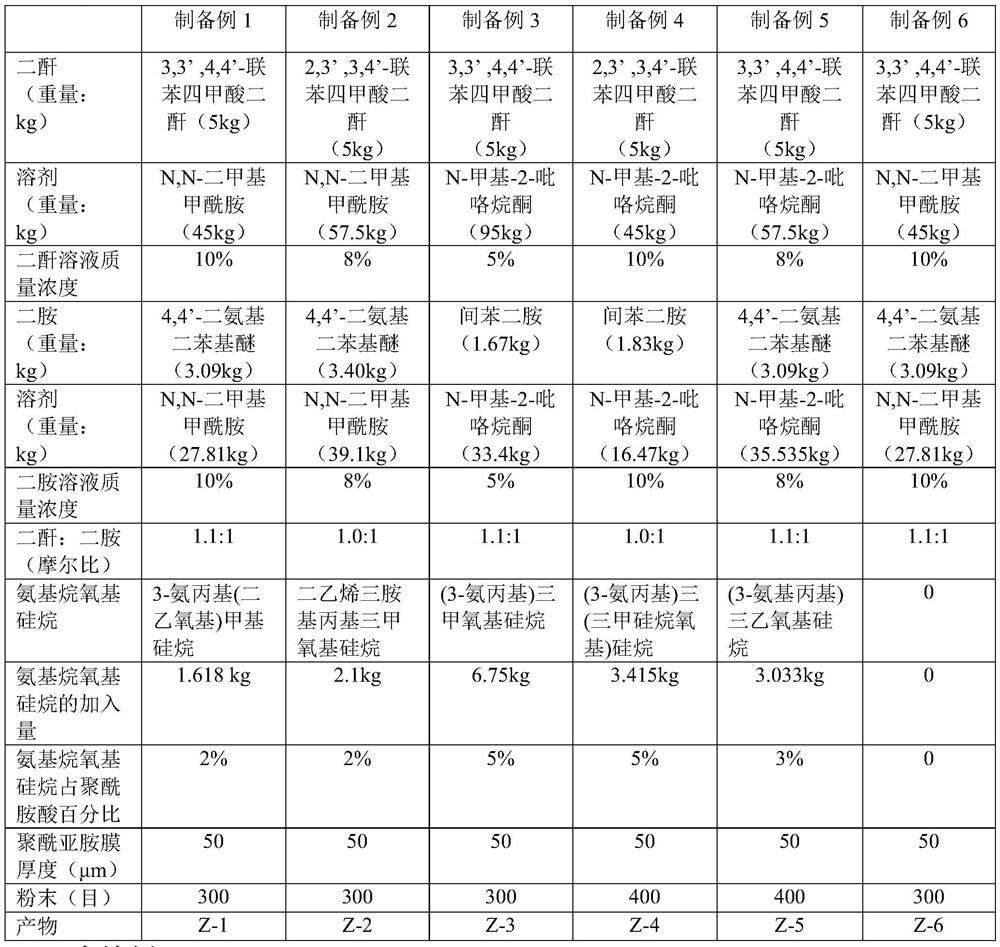

[0027] Silicone-modified polyimide powder was prepared according to the following steps (1)-(4), wherein the raw materials, proportions and reaction conditions are shown in Table 1.

[0028] (1) Dissolving the dianhydride in a solvent to prepare a dianhydride solution with a mass concentration of 5-10%, and adding dropwise a diamine solution of the same solvent with a mass concentration of 5-10% in the solution, wherein the dianhydride and the dianhydride The molar ratio of the amine is 1.0-1.1:1 to obtain a polyamic acid solution;

[0029] (2) After the reaction finishes, add 2-5% aminoalkoxysilane of polyamic acid solution quality, make it fully react;

[0030] (3) preparing the product of step (2) into an aminoalkoxy-modified polyimide film with a thickness of 5-80 μm by solution casting, salivation, or solution extrusion;

[0031] (4) Shear and pulverize the film to 400-500 mesh powder.

[0032] Table 1

[0033]

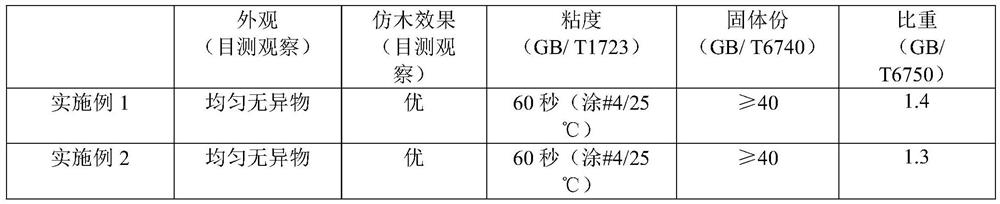

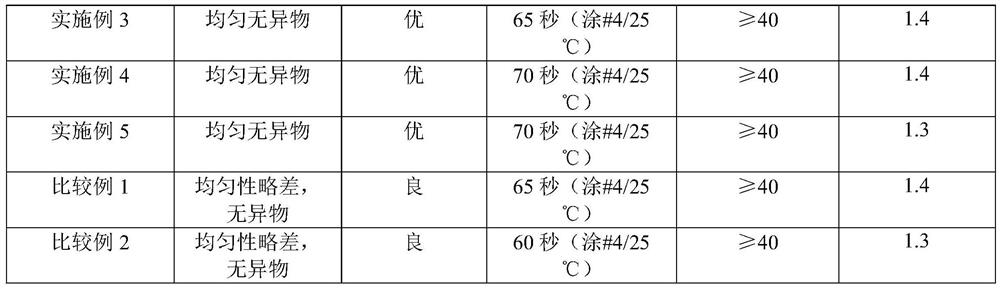

Embodiment 1

[0035] Dissolve 100kg of bisphenol A type epoxy resin (E-03 type) and 150kg of silicone modified polyimide powder Z-1 in 400kg of solvent (dimethyl carbonate: ethanol volume ratio 1:1), in 200 Mix at ℃ for 5 hours;

[0036]Each component (sodium pyrophosphate 64kg, trisodium phosphate 64kg, organobentonite 96kg, diatomite 64kg, hibiscus red colored sand 32kg, blue gray colored sand 18kg, snowflake white colored sand 12kg) as auxiliary agents was put all at 70°C The auxiliary agent is mixed and added to the above solvent mixture to obtain the imitation wood composite paint of the present invention.

Embodiment 2

[0038] Dissolve 150kg of bisphenol F epoxy resin (EP-4901E) and 150kg of silicone modified polyimide powder Z-2 in 600kg of solvent (ethanol: n-butanol volume ratio 1:2), at 200°C Mix for 5 hours;

[0039] All ingredients (sodium pyrophosphate 18kg, sodium metasilicate 18kg, organobentonite 27kg, mica powder 18kg, cherry red colored sand 9kg, blue gray colored sand 6kg, snowflake white colored sand 4kg) used as auxiliary agents were mixed at 70°C The auxiliary agent is mixed and added to the above solvent mixture to obtain the imitation wood composite paint of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com