A coal-water slurry dispersant

A technology of dispersant and coal-water slurry, which is used in fuel additives, liquid carbon-containing fuels, petroleum industry, etc. Increase the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

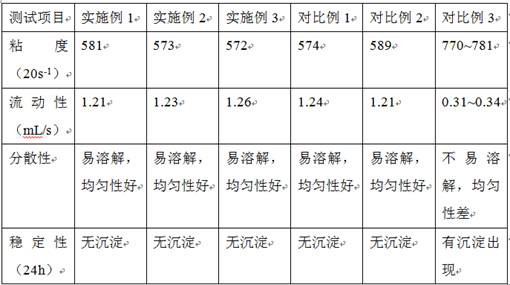

Examples

preparation example Construction

[0030] The preparation method of composite dispersion A includes the following steps:

[0031] (1) Mix potassium humate, KOH, and water at a mass ratio of 5~8:1:20~30, stir for 2~5h at 300~450r / min, stand for 20~24h, take the supernatant, use a concentration of 0.1 Adjust the pH of the mol / L HCl solution to 2~3, let stand for 20~24h, suction filter, take the filter residue and wash it with 2~5 times the mass of the filter residue with deionized water, then move it to 60~75℃ oven to dry to low water content Less than 5%, get dry matter;

[0032] (2) At 28~40℃, take acrylic acid according to the mass ratio of 3:2:30~40, add KOH, water and mix, magnetically stir at 250~400r / min for 25~40min, add 2~5 times the dry matter of acrylic acid to mix , Heat up to 75~85℃, add initiator with 15~20% of acrylic acid quality, heat preservation and react for 2~4h, cool to room temperature naturally, and discharge the material to obtain composite dispersion A.

[0033] The preparation method of comp...

Embodiment 1

[0042] Auxiliary agent: Mix carboxymethyl cellulose, sodium phosphate and maleic anhydride according to the mass ratio of 3:1:0.1 to obtain the auxiliary agent.

[0043] Dopamine solution: Mix dopamine hydrochloride, sodium carbonate, and calcium chloride according to a mass ratio of 6:1:0.1 to obtain a dopamine solution.

[0044] Surfactant: Mix the sodium dodecylbenzene sulfonate and sodium secondary alkyl sulfonate 4:1 in parts by mass to obtain the surfactant.

[0045] Excipients: Mix sodium alginate and dichloroethane according to a mass ratio of 4:3 to obtain auxiliary materials.

[0046] Initiator: ammonium persulfate.

[0047] Solvent A: Mix methanol and ethylenediamine at a mass ratio of 1:3 to obtain solvent A.

[0048] Solvent B: Mix formaldehyde, ammonium carbonate, and water at a mass ratio of 1:2:15 to obtain a solvent.

[0049] The preparation method of composite dispersion A includes the following steps:

[0050] (1) Mix potassium humate, KOH, and water according to the mas...

Embodiment 2

[0061] Additives: Mix carboxymethyl cellulose, sodium phosphate, and maleic anhydride in a mass ratio of 3:2:0.1 to obtain the additives.

[0062] Dopamine solution: Mix dopamine hydrochloride, sodium carbonate, and calcium chloride according to a mass ratio of 6:2:0.1 to form a dopamine solution.

[0063] Surfactant: Take 4:2 parts by mass and mix sodium dodecylbenzene sulfonate and sodium secondary alkyl sulfonate to obtain surfactant.

[0064] Excipients: Mix sodium alginate and dichloroethane according to the mass ratio of 4:6 to obtain auxiliary materials.

[0065] Initiator: sodium persulfate.

[0066] Solvent A: Mix methanol and ethylenediamine at a mass ratio of 4:3 to obtain solvent A.

[0067] Solvent B: Mix formaldehyde, ammonium carbonate, and water at a mass ratio of 1:5:20 to obtain a solvent.

[0068] The preparation method of composite dispersion A includes the following steps:

[0069] (1) Mix potassium humate, KOH, and water at a mass ratio of 8:1:30, stir at 450r / min for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com