Complex plating solution, preparation method and application thereof

A composite electroplating and plating solution technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problems of short circuit system of electronic devices, affect device reliability, and easily produce tin whiskers, etc., achieve mature preparation process, release internal stress, reduce internal driving force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

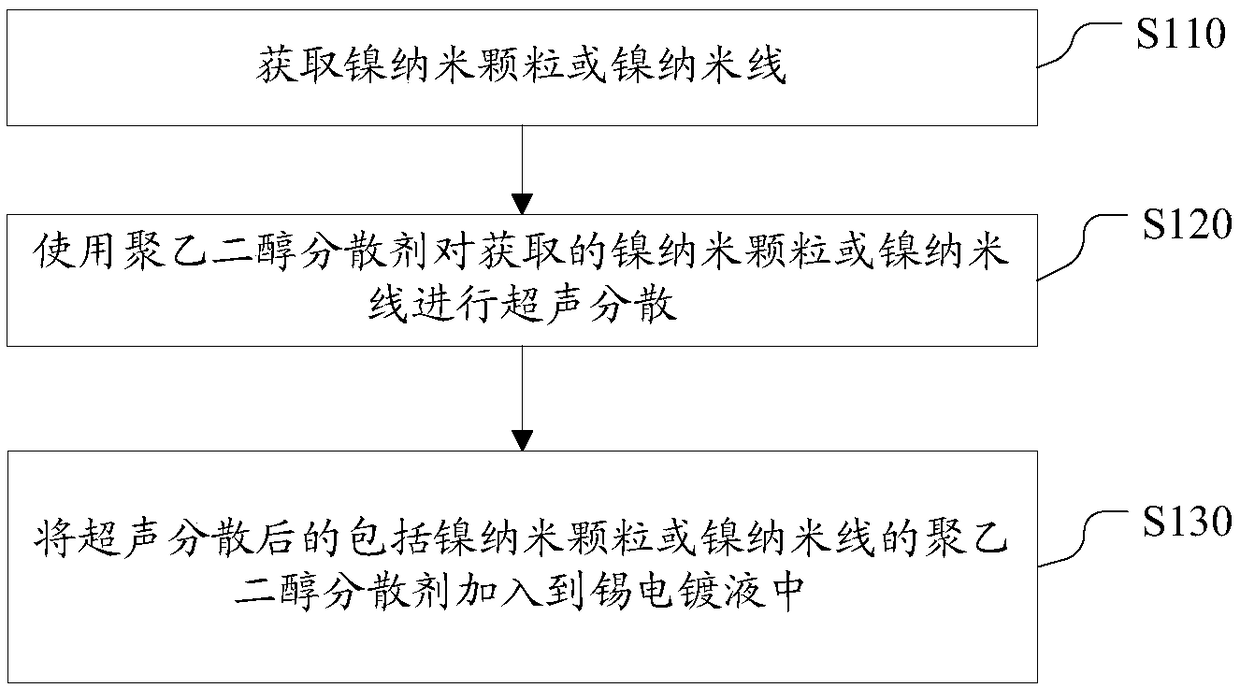

[0064] figure 1 It is a schematic flowchart of a method for preparing a composite electroplating solution provided by an embodiment of the present invention. Such as figure 1 Shown, the preparation method of this composite electroplating solution comprises:

[0065] Step S110, obtaining nickel nanoparticles or nickel nanowires.

[0066] In this embodiment, the obtained nickel nanoparticles or nanowires may be existing or prepared by using an existing process. Wherein, the nickel nanoparticle or nickel nanowire has a preset size.

[0067] Step S120, ultrasonically dispersing the obtained nickel nanoparticles or nickel nanowires using a polyethylene glycol dispersant.

[0068] In order to disperse the nickel nanoparticles or nickel nanowires uniformly so that they can be dispersed in the tin electroplating solution, in this embodiment, the nickel nanoparticles or nickel nanowires are ultrasonically dispersed using a polyethylene glycol dispersant. Specifically, the obtained...

Embodiment 1

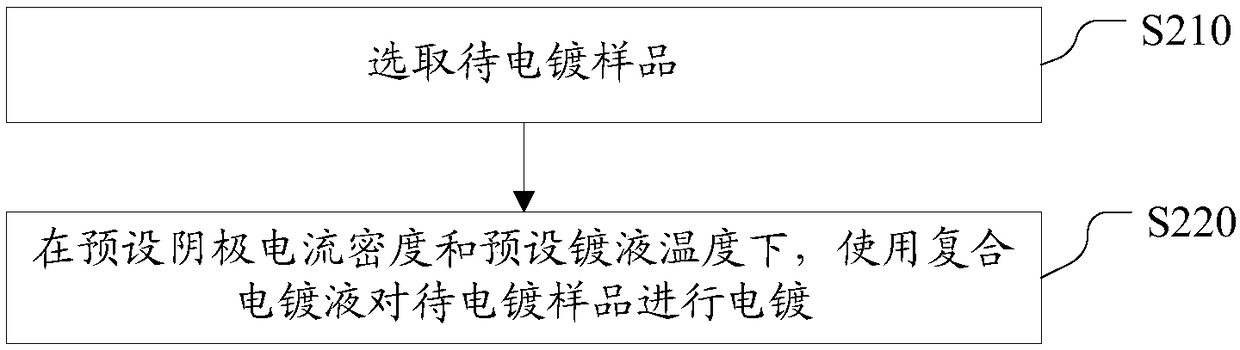

[0095] Select the TO220 lead frame as the electroplating sample, the substrate is copper alloy C194, and the process flow is to remove flash, high pressure water, chemical degreasing, deoxidation, activation, electroplating, neutralization, and hot water washing. Specifically, the time for flash removal is 1min, temperature 60 degrees Celsius, high pressure water pressure 200kg, chemical degreasing 20s, degreasing temperature 50 ℃, use 5% concentration of sodium persulfate solution for deoxidation, use 10% concentration of methanesulfonic acid solution for activation; The electroplating solution is a tin methanesulfonate matte plating solution with nickel nanoparticles added, and the composition of the plating solution is: 220ml / L of stannous methanesulfonate, 80ml / L of methanesulfonic acid, 50ml / L of additives, and the The mass concentration of nickel nanoparticles is 0.3%, the particle size of nickel nanoparticles is 200nm, the volume of the electroplating tank is 300L, the e...

Embodiment 2

[0097]The TO220 lead frame is selected as the electroplating sample, the base material is copper alloy C194, and the process flow is deflashing, high pressure water, chemical degreasing, deoxidation, activation, electroplating, neutralization, and hot water washing. Specifically, the time for de-flashing is 1min, the temperature is 60 degrees Celsius, the high-pressure water pressure is 200kg, the chemical degreasing is 20s, the degreasing temperature is 50°C, 5% sodium persulfate solution is used for deoxidation, and 10% sulfuric acid solution is used for activation. The composite electroplating solution that electroplating uses is the sulfuric acid system matte electroplating solution that adds nickel nanoparticle, and plating solution consists of: stannous sulfate 20g / L, sulfuric acid 160g / L, additive 40ml / L, the nickel nanoparticle in the composite electroplating solution The mass concentration is 0.3%, the particle size of nickel nanoparticles is 200nm, the volume of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com