Preparation method of copper-based desulfurizer, copper-based desulfurizer and preparation system

A desulfurizer, copper-based technology, applied in the preparation of copper-based desulfurizers, copper-based desulfurizers and preparation systems, can solve the problems of material waste, acid rain, environmental pollution, etc., to ensure the safety of human life, good dispersion performance, The effect of enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

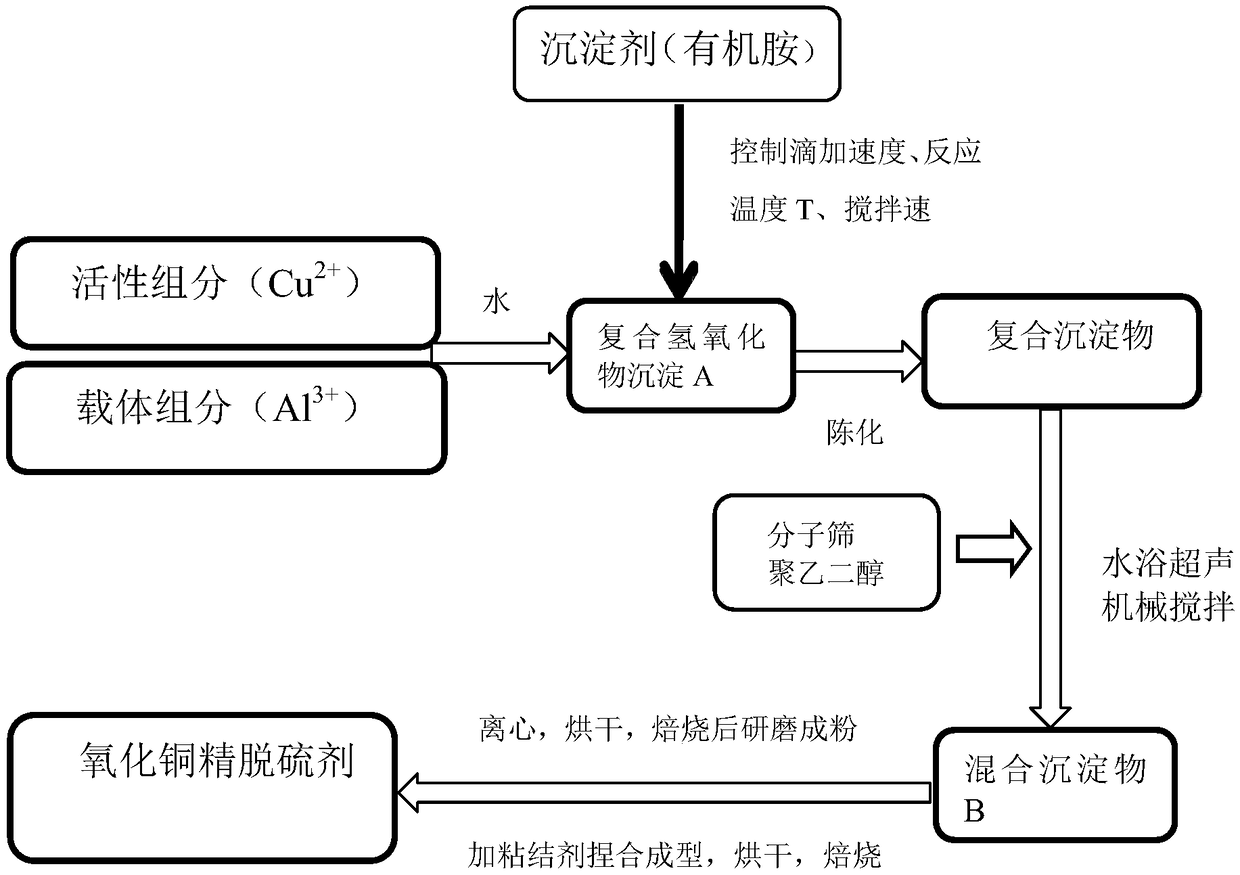

[0051] figure 1 , the preparation method of the copper-based desulfurizer provided by the embodiment of the present invention comprises:

[0052] S101: Select Cu 2+ As the source of active components, add a mixed solution prepared by one or several soluble salts of metal aluminum salts with a mass fraction of 30% to 70% relative to the main active component, and use organic amines such as alcohol amines , the polyene polyamine is used as a precipitating agent, the pH is controlled under the conditions of heating in a water bath and mechanical stirring, and a composite hydroxide precipitate A is obtained by coprecipitation;

[0053] S102: Aging the obtained composite colloid A to a stable state, then adding 1-10% molecular sieve as a channel aid, 1-10% polyethylene glycol as a dispersant, heating and stirring mechanically after ultrasonication in a water bath, and controlling 8<pH<11 , to obtain mixed precipitate B;

[0054] S103: The obtained mixed sediment B is centrifuged...

Embodiment 1

[0057] 1. Weigh 0.04mol of AlCl 3 .6H 2 O, 0.08mol of Cu(NO 3 ) 2 , configured as Cu(NO 3 ) 2 The solution A with a mass fraction of 10% was poured into a 500mL three-necked flask for later use.

[0058] 2. Weigh again 0.121 mol of diethylenetriamine (EDTA), and configure it into 10% lye B for later use.

[0059] 3. Will be loaded with Cu(NO 3 ) 2 Place the three-neck flask of solution A in a water bath at 70°C, start stirring at 400r / min, and add alkali solution B to Cu(NO 3 ) 2 In solution A, the dropping time is controlled at about 1.5h, and the control is 8

[0060] 4. After the dropwise addition was completed, continue to keep warm and stir for 1 hour, then stop the reaction, and place the obtained precipitate at the reaction temperature to age for 18 hours.

[0061] 5. After the aging is completed, add 5% 13X molecular sieve as a channel aid and 5% polyethylene glycol as a dispersant, ultrasonicate for 1 hour in a water bath at 70°C, and centrifuge and w...

Embodiment 2

[0066] 1. Weigh 0.06mol of AlCl 3 .6H 2 O, 0.08mol of Cu(NO 3 ) 2 , configured as Cu(NO 3 ) 2 The solution A with a mass fraction of 10% was poured into a 500mL three-necked flask for later use.

[0067] 2. Weigh again 0.147 mol of diethylenetriamine (EDTA), and configure it into 10% lye B for later use.

[0068] 3. Will be loaded with Cu(NO 3 ) 2 Place the three-neck flask of solution A in a water bath at 70°C, start stirring at 400r / min, and add alkali solution B to Cu(NO 3 ) 2 In solution A, the dropping time is controlled at about 1.5h, and the control is 8

[0069] 4. After the dropwise addition is completed, continue to keep warm and stir for 1 hour, then stop the reaction to obtain the obtained precipitate and age it at the reaction temperature for 18 hours.

[0070] 5. After the aging is completed, add 5% 13X molecular sieve as a channel aid and 5% polyethylene glycol as a dispersant, ultrasonicate for 1 hour in a water bath at 70°C, and centrifuge and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com