Purification method of gypsum containing raw material

A purification method and raw material technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve problems such as poor economy, high energy consumption, and low gypsum value, and achieve improved purity and high product purity , The effect of thorough separation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

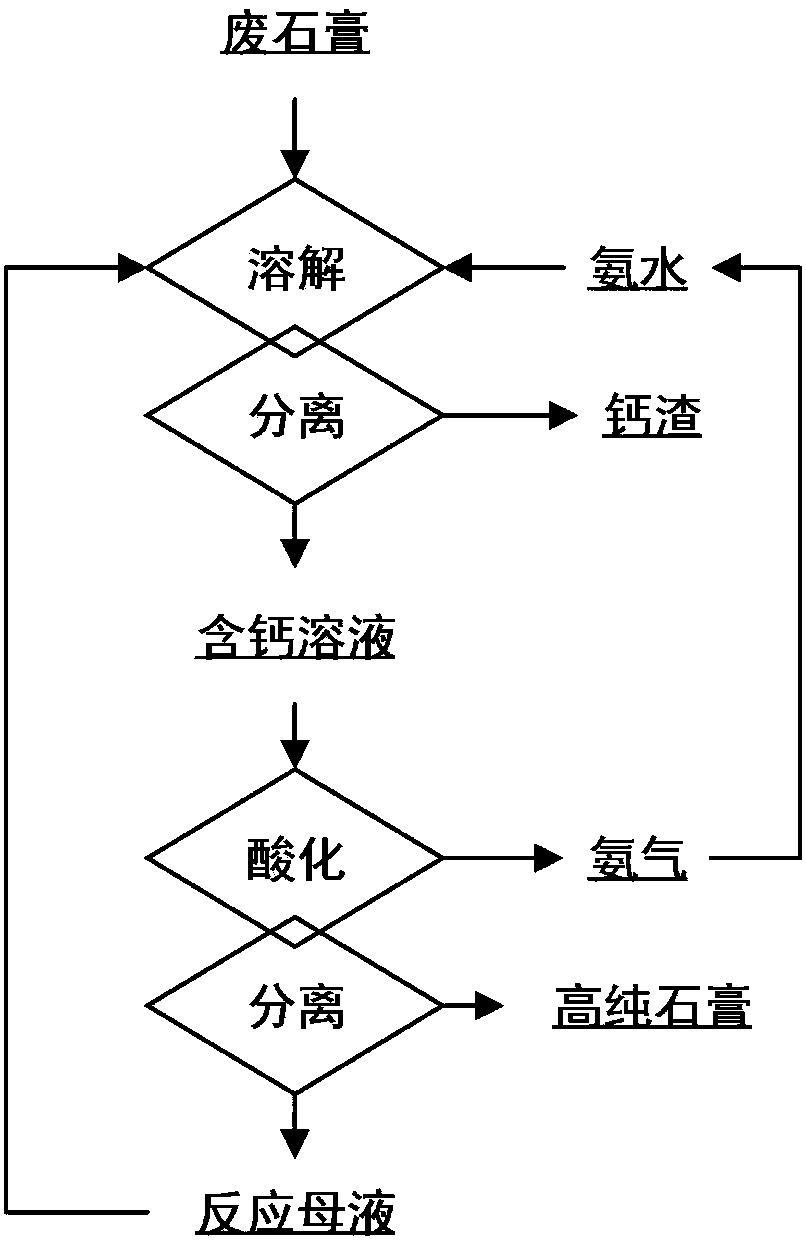

Image

Examples

Embodiment 1

[0055] 1) Configure 50L containing 1.5mol / L ethylenediamine, 0.5mol / L propylamine, 1.0mol / L histidine, 0.5mol / L ethanol, 0.5mol / L sodium sulfate, 0.8mol / L nickel sulfate, 0.5g / Add 4.3kg of phosphogypsum to an aqueous solution of L sodium lauryl sulfate at 90°C, use sodium hydroxide to maintain the pH value of the solution between 10.0-10.5, react for 3.0 hours, and filter to obtain a calcium-containing solution.

[0056] 2) Add 20% sulfuric acid solution to the calcium-containing solution obtained in step 1), so that the pH value is gradually reduced to below 7.0, during which the reaction temperature is controlled between 90-95° C., and the reaction time is 8 hours. After the reaction is completed, filter and wash , to obtain calcium sulfate and reaction mother liquor.

Embodiment 2

[0058] 1) Prepare 100L of reaction solution containing 1.5mol / L ethylenediaminetetraacetic acid, 0.2mol / L glutamic acid, 0.5mol / L sodium sulfate, 2.0mol / L copper nitrate, and 2.5mol / L sodium nitrate at 60°C Add 2.8 kg of desulfurized gypsum, use ammonia water to maintain the pH value of the solution between 9.0-9.5, react for 5.0 hours, and filter to obtain a calcium-containing solution.

[0059] 2) Transfer the calcium-containing solution obtained in step 1) to another reactor, reduce the pressure to 50kpa, volatilize the ammonia gas in the solution, and gradually reduce the pH value to below 6.0, during which the reaction temperature is controlled between 60-65°C After the reaction, filter and wash to obtain calcium sulfate and reaction mother liquor.

[0060] 3) The reaction mother liquid obtained in step 2) is adjusted to a pH value between 9.0-9.5 with ammonia water, and returned to step 1) as a reaction liquid for recycling.

Embodiment 3

[0062] 1) Configure 500L containing 1.0mol / L nitrilotriacetic acid, 0.1mol / L ethylenediamine diacetic acid, 1.0mol / L ethylenediamine, 0.2mol / L glycerol, 3.0mol / L ammonium sulfate, 0.8mol / L Add 56kg of phosphogypsum to the copper sulfate reaction solution at 80-85°C, use ammonia water to maintain the pH value of the solution between 10.4-11.0, react for 2.5 hours, and filter to obtain a calcium-containing solution.

[0063] 2) Transfer the calcium-containing solution obtained in step 1) to another reactor, and continuously feed air into it to volatilize the ammonia gas in the solution, and gradually reduce the pH value of the solution to below 8.0, during which the reaction temperature is controlled at 80-85 After the reaction is completed, filter and wash to obtain calcium sulfate and reaction mother liquor.

[0064] 3) Step 2) obtained reaction mother liquor, returns step 1) as reaction liquid and recycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com